Immobilized enzyme conversion preparation method for allyl isothiocyanate

A technology of isothiocyanate and immobilized enzyme, applied in the direction of immobilization on or in inorganic carrier, fermentation, etc., can solve the problems of different hydrolyzed products, complex synthesis process, high toxicity of reagents, etc., to improve the application value and technology Advanced, method-unique effects

Inactive Publication Date: 2015-06-03

BEIJING UNIV OF AGRI

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most of the isothiocyanates are prepared by chemical synthesis in the market. This product has certain chemical hazards and cannot be directly used in food preservation. It is an inevitable trend to replace chemically synthesized preservatives with natural food preservatives.

The artificially synthesized allyl isothiocyanate is very risky in the food industry due to its complex synthesis process and high toxicity of reagents.

However, in the natural conversion process of allyl isothiocyanate, there are defects such as uncontrollable, low yield, and high cost, and the hydrolyzed products vary with conditions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

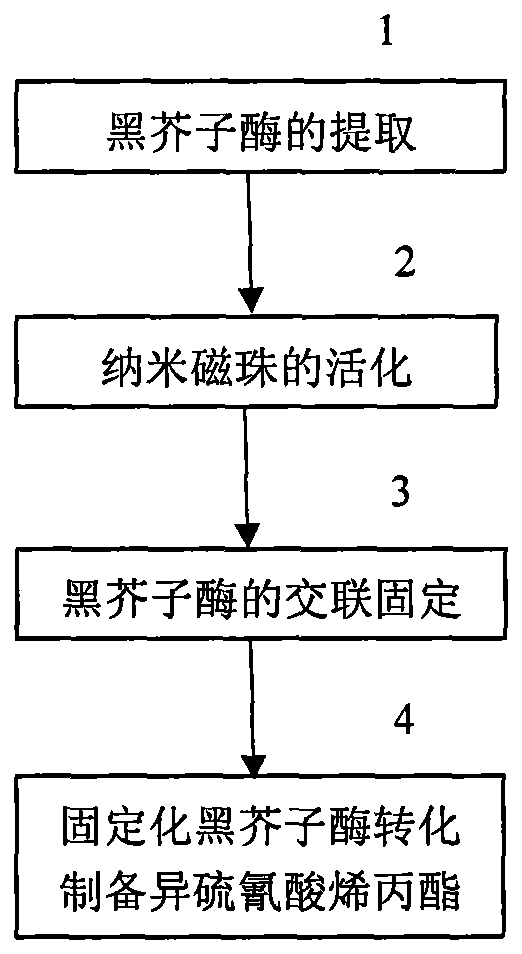

[0007] Specific examples are given by the legends. The legend shows the process flow chart of extracting myrosinase from horseradish, which includes extraction of myrosinase 1, cross-linking and immobilization of myrosinase 2, activation of nano-magnetic beads 3, conversion of immobilized myrosinase to prepare iso Allyl Thiocyanate 4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an immobilized enzyme conversion preparation method for allyl isothiocyanate, and belongs to the technology of preparation. The preparation method comprises the following steps: extracting myrosinase; performing magnetic bead activating; performing cross-linking immobilizing on the myrosinase; converting the immobilized myrosinase to prepare allyl isothiocyanate. The problems that degradation products are uncontrollable, the conversion rate of a target product is low, the cost is high and the like in the natural conversion process of allyl isothiocyanate are solved; the reutilization of an enzyme is realized; the application value of the enzyme is greatly improved; the requirements on environment friendliness and safety are really met; meanwhile, the production cost is low; the method is high in practicability and generalization performance.

Description

technical field [0001] The invention relates to a method for preparing an immobilized enzyme of allyl isothiocyanate, which belongs to the preparation technology. Background technique [0002] Allyl isothiocyanate (AITC for short) is the main flavor substance of mustard oil. Due to its unique taste and antibacterial properties, recent studies have found that it can inhibit the growth of cancer cells, and it can also replace methyl bromide as soil in agriculture. Disinfectants, so allyl isothiocyanate has a wide range of applications in food additives, food antibacterial and antiseptic, medical anticancer and soil disinfection. At present, most of the isothiocyanates are prepared by chemical synthesis in the market. This product has certain chemical hazards and cannot be directly used in food preservation. It is an inevitable trend to replace chemically synthesized preservatives with natural food preservatives. Due to the complex synthesis process and high toxicity of the re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12P13/00C12N11/14

Inventor 丁轲陈湘宁许丽刘佳李斌军杜斌张海英韩涛赵瑞雪

Owner BEIJING UNIV OF AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com