A kind of Tibetan paper and its production method

A production method and technology for Tibetan paper, applied in the field of Tibetan paper, can solve problems such as incompatibility and insufficient finish of Tibetan paper, and achieve the effects of optimizing uniformity and quality, improving finish, and being widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

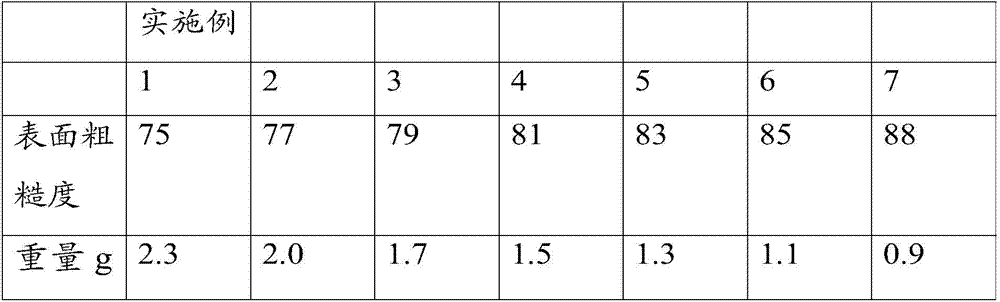

Examples

Embodiment 1

[0037] A method for making Tibetan paper, comprising the following steps:

[0038] Soaking: Soak 10 catties of chamaejasba root system in stream water to remove the outer layer of brown bark and soil. After soaking for about 3 days, the paper material is dried in the sun to prevent the bast in the middle of the rhizome from rotting. The rhizomes of chamaejasma chamaejasma after soaking and drying are put into sacks for later use.

[0039] Picking up the skin: put the soaked and dried rhizome of chamaejasma chamaejasma on a large disc-shaped stone, pound it with a hammer, the degree of pounding is based on the degree of pounding the outer layer of brown skin, and remove the outer brown skin and inner core. Only the bast in the middle of the rhizome is left, and then the bast of the rhizome is torn off along the fiber direction, while constantly picking out the brown bark and other sundries left in the paper material.

[0040] Cooking material: put the paper material beaten in...

Embodiment 2

[0046] A method for making Tibetan paper, comprising the following steps:

[0047] Soaking: Soak 10 catties of chamaejasba root system in stream water to remove the outer layer of brown bark and soil. After soaking for about 3 days, the paper material is dried in the sun to prevent the bast in the middle of the rhizome from rotting. The rhizomes of chamaejasma chamaejasma after soaking and drying are put into sacks for later use.

[0048] Picking up the skin: put the soaked and dried rhizome of chamaejasma chamaejasma on a large disc-shaped stone, pound it with a hammer, the degree of pounding is based on the degree of pounding the outer layer of brown skin, and remove the outer brown skin and inner core. Only the bast in the middle of the rhizome is left, and then the bast of the rhizome is torn off along the fiber direction, while constantly picking out the brown bark and other sundries left in the paper material.

[0049] Cooking material: put the paper material beaten in...

Embodiment 3

[0056] A method for making Tibetan paper, comprising the following steps:

[0057] Soaking: Soak 10 catties of chamaejasba root system in stream water to remove the outer layer of brown bark and soil. After soaking for about 3 days, the paper material is dried in the sun to prevent the bast in the middle of the rhizome from rotting. The rhizomes of chamaejasma chamaejasma after soaking and drying are put into sacks for later use.

[0058] Picking up the skin: put the soaked and dried rhizome of chamaejasma chamaejasma on a large disc-shaped stone, pound it with a hammer, the degree of pounding is based on the degree of pounding the outer layer of brown skin, and remove the outer brown skin and inner core. Only the bast in the middle of the rhizome is left, and then the bast of the rhizome is torn off along the fiber direction, while constantly picking out the brown bark and other sundries left in the paper material.

[0059] Cooking material: put the paper material beaten in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com