Novel hollow plate hinge joint structure and construction method thereof

A construction method and technology of hollow slabs, applied to bridge parts, erection/assembly of bridges, bridge materials, etc., can solve problems such as damaged bridges, and achieve the effects of improving crack resistance, simple construction methods, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

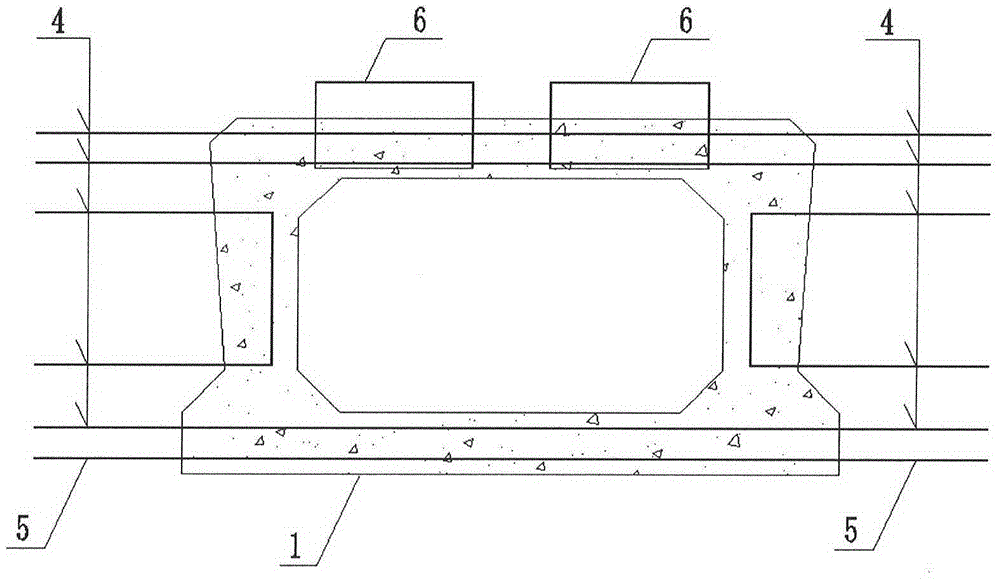

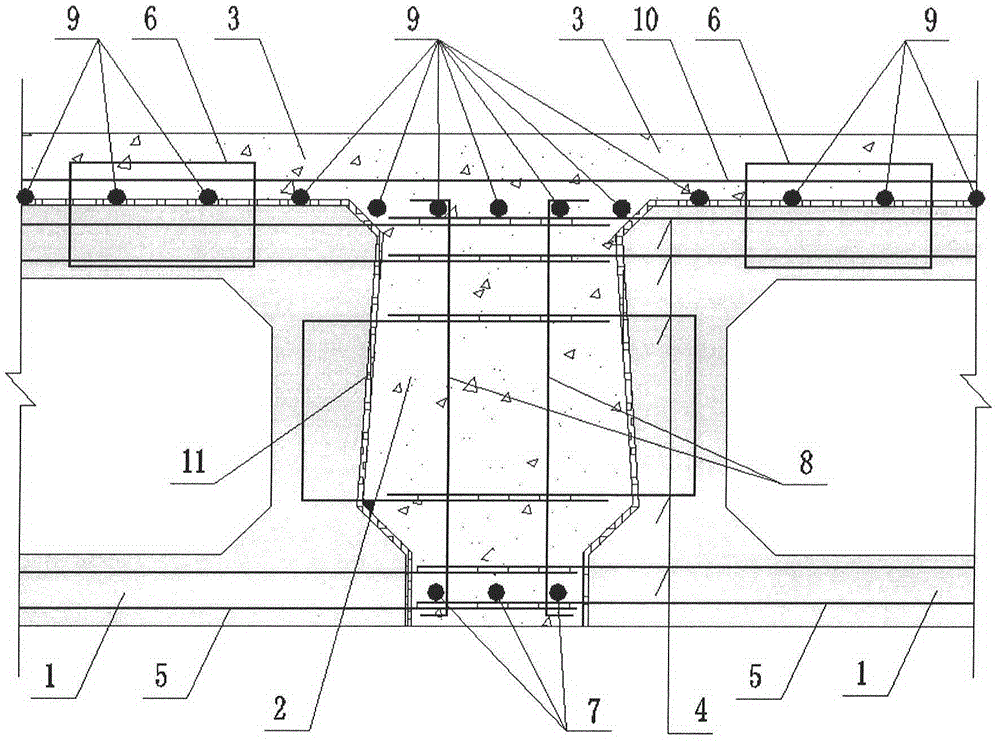

[0039] In this embodiment, the dimensions of the hollow slab 1 of the bridge are 1296×124×75 cm in length, width and height, and there are hinge joints 2 for pouring concrete between the hollow slabs 1 , and above the hollow slab 1 and the hinge joint 2 is the cast-in-place layer 3 of the bridge deck. , Hinge 2 width K=35cm.

[0040] In this specific implementation, the hollow slab is firstly prefabricated: the concrete of the hollow slab 1 is poured with a formwork, and the anchoring steel bar 6 is pre-embedded on the top surface of the hollow slab 1. The diameter of the horizontal lapping steel bars 4 is 16mm, and the longitudinal spacing is 12.5cm; the diameter of the transverse bending steel bars 5 pre-buried on the side of the hollow slab 1 is 28mm, and the longitudinal spacing is 10cm. After the prefabricated hollow panels 1 are hoisted in place piece by piece, as figure 2As shown, the chemical adhesive 11 epoxy resin is applied on the side and top surface of the hollo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bar diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com