Volute mixed flow water turbine unit special for cooling tower

A technology of mixed flow and hydraulic turbines, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of large floating water loss, inability to guarantee, and affect cooling effect, etc., and achieve small floating water loss, simple structure, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

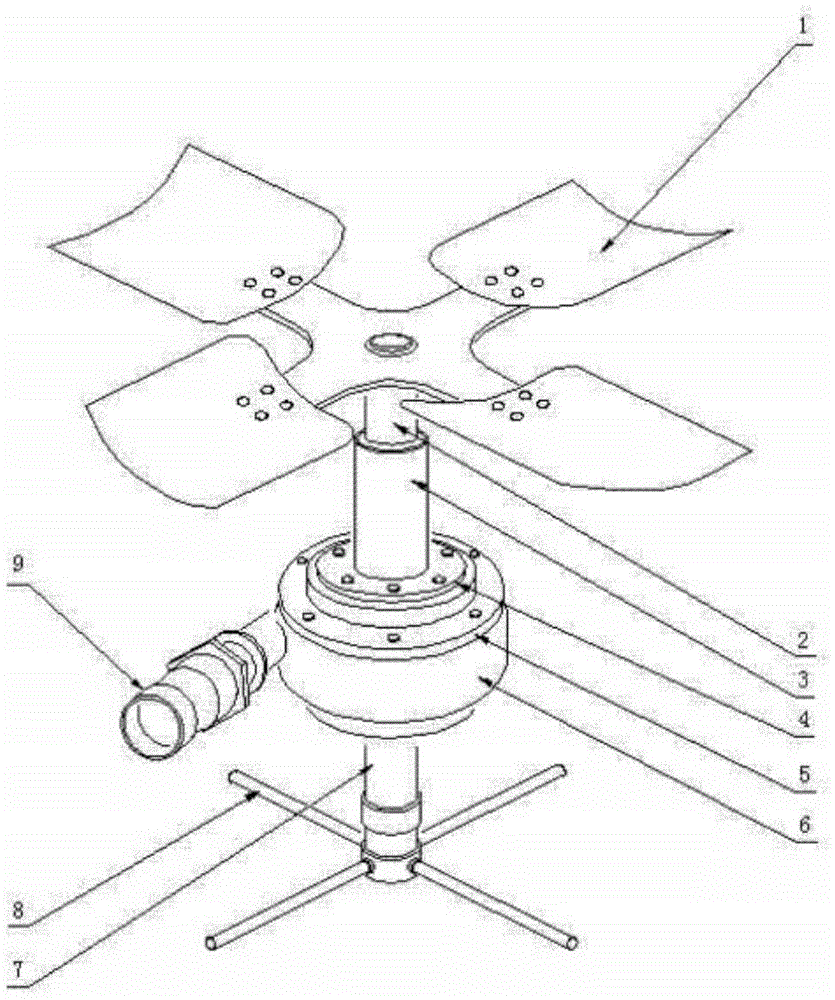

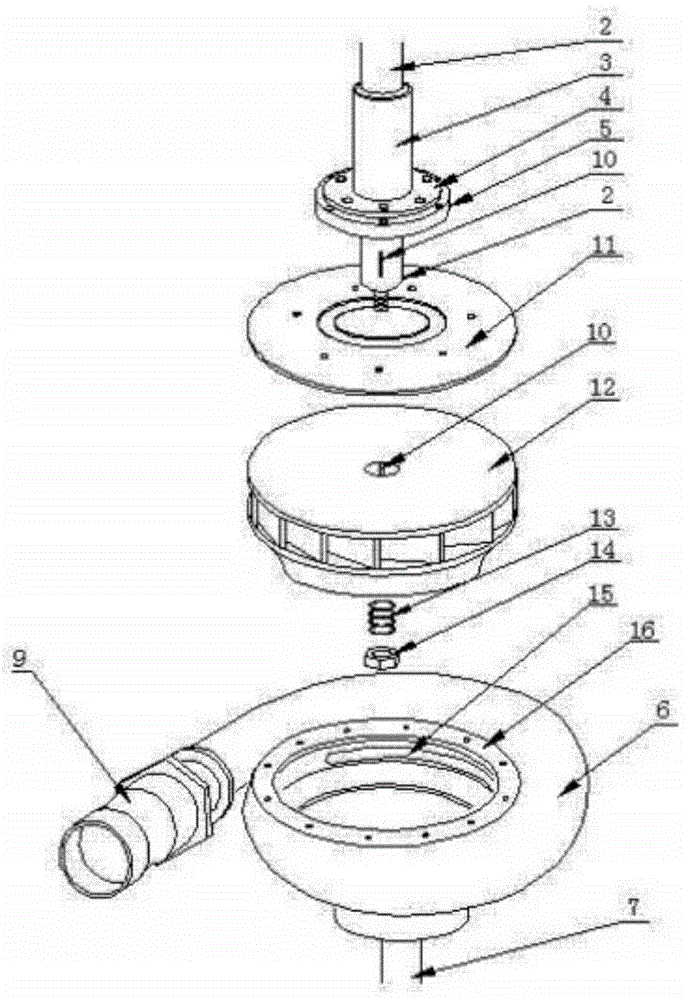

[0010] See figure 1 with figure 2 As shown, the special volute Francis turbine unit for cooling tower is composed of three parts: the volute Francis turbine in the middle, the fan 1 in the upper part, and the water distributor 8 in the lower part. The volute Francis turbine consists of two parts: a horizontal cavity volute 6 and a wheel fan system installed in the central cavity. Volute 6 protruding part is cavity water inlet pipe 9, and from this pipe and volute 6 tangent intersects, has horizontal water outlet narrow mouth 15 on the inner wall of ring volute 6 housings. The water inlet pipe 9 communicates with the draft pipe of the central air-conditioning circulating water system. The upper and lower end surfaces of the volute 6 are connected with a connecting disk 16 . The wheel fan system consists of a fan shaft 2, a shaft sleeve 3 that passes through it from top to bottom, upper, middle and lower flanges 4, 5, 11, a circular wheel fan blade 12 with a hole in the cent...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap