A new type of rotating plate resistance type high-efficiency power generation device

A power generation device, resistance-type technology, applied in the field of new rotating plate resistance-type high-efficiency power generation devices, can solve the problems of not maximizing the force difference, different forces on the blades on both sides of the central shaft, and poor power generation effect, etc., to achieve It has a wide range of applications and the effect of improving the utilization rate of wind energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

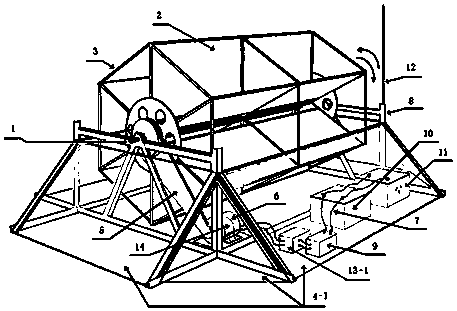

[0057] Embodiment 1: When used for wind power generation, the central axis is placed horizontally on the ground, and the whole machine support is placed under the central axis. The whole machine has a stable structure like a pyramid, and the drainage plate (4-1) is placed under the central axis. The whole machine support One or more sides (the diversion plate plays the role of blocking the wind from blowing to the blades below the central axis and allowing the wind to only blow to the blades above the central axis, and also slows down the impact of the wind on the whole machine and guides part of the wind to turn blowing to the blades rotating to a position above the central axis). When the wind blows, the blades below the central axis of the machine are covered by the deflector plate, so the force is almost zero, and only the blades that turn to the part above the central axis receive the impact of wind energy, generate rotating mechanical motion, and drive power generation th...

Embodiment 2

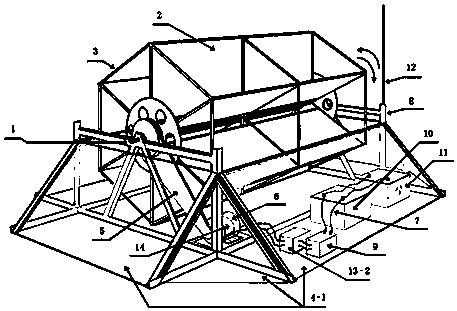

[0058] Embodiment two: the wind power generator of embodiment one form, change its generating unit into alternator: when the electric energy output unit of connection comprises AC-DC converter (13-2), output controller, cable, when storage battery , the generated power can be used by electrical appliances using direct current. When the connected electric energy output unit includes an AC-DC converter (13-2), an output controller, a cable, a storage battery, and an inverter, the generated power can be used for alternating current The use of electrical appliances (see the attached instructions for the form) figure 2 ); can also be incorporated into the external network.

Embodiment 3

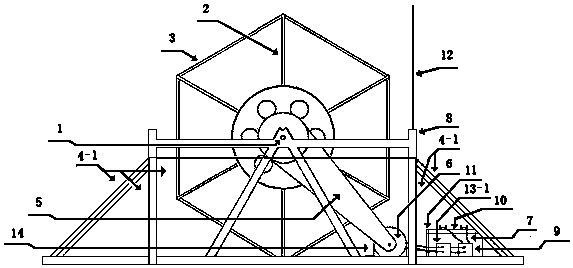

[0059] Embodiment 3: Turn the machine in the form of Embodiment 1 upside down, put the part below the central axis into the water, connect the bracket of the whole machine with the embankment or bridge and fix it, then it can be used as a hydroelectric generator (the lightning rod needs to be changed to become a whole machine highest point)

[0060] (see the attached manual for the form) Figure 9 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com