Flashing liquid-separation integration device

An integrated device and liquid separation technology, which is applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as high operating cost, fast liquid discharge speed, and increased liquid volume in liquid separation tanks, so as to improve reliability Sex and stability, shorten the construction period, and reduce the effect of land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In order to overcome the existing problems of slow liquid discharge, easy blockage, insufficient liquid storage capacity, and high labor cost, the present invention provides a flash liquid separation integrated device, which has a combined device for flash evaporation, venting liquid separation, and reduces investment. Reduce land occupation and shorten the construction period, and realize automatic liquid drainage under normal operating conditions of the gas gathering station, and emergency liquid drainage capabilities under slug flow conditions, so as to improve the reliability and stability of station operation.

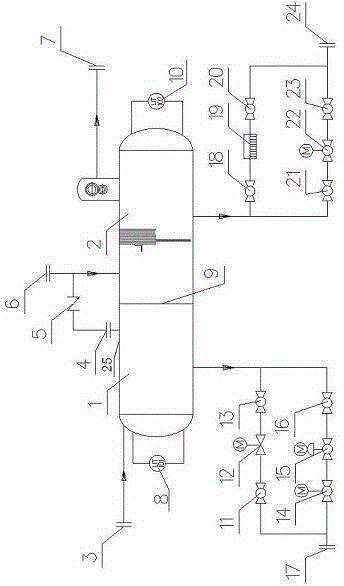

[0026] Such as figure 1 As shown, a flash liquid separation integrated device includes a tank body 25, and the tank body 25 is divided into a flash chamber 1 and a liquid separation chamber 2 through a blockage 9 along the vertical direction;

[0027] One end inlet of the flash chamber 1 communicates with the first liquid inlet 3 through a pipeline, the upp...

Embodiment 2

[0039] On the basis of Embodiment 1, a first electric ball valve 12 connected in parallel with the fourth electric ball valve 15 is also provided between the lower outlet of the flash chamber 1 and the first liquid discharge port 17, and the first electric ball valve 12 is electrically connected to the first liquid level gauge 8, and a first manual ball valve 11 and a second manual ball valve 13 are respectively arranged on the pipelines at both ends of the first electric ball valve 12.

[0040]When the amount of liquid coming from the upstream is large, slug flow occurs in the gas production pipeline, and the liquid volume increases significantly in a short period of time, the third electric ball valve 15 cannot discharge enough liquid, and when the liquid level reaches a high level, start emergency liquid discharge. The first electric ball valve 12 starts to discharge liquid, and when the liquid level is discharged to a low liquid level, the first electric ball valve 12 is cl...

Embodiment 3

[0043] Based on the above two embodiments, a fourth electric ball valve 22 connected in parallel with the steam trap 19 is also provided between the lower outlet of the liquid separation chamber 2 and the second liquid discharge port 24. The pipelines at both ends of the ball valve 22 are respectively provided with a sixth manual ball valve 21 and a seventh manual ball valve 23 .

[0044] The function of the steam trap 19 is to discharge the condensed water, air and carbon dioxide gas in the steam system as soon as possible; at the same time, it can automatically prevent the leakage of the steam to the greatest extent. In this embodiment, after two gas-liquid separations, the liquid is discharged through the trap 19, and the trap 19 liquefies the gas carried in the liquid to ensure the safety of the liquid discharge and prevent the gas from leaking downward.

[0045] When the emergency liquid volume in the gas-gathering station increases significantly, the drain valve 19 does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com