Biomass boiler and method for using heat energy by biomass boiler

A biomass boiler and biomass fuel technology, which is applied in the direction of combustion methods, lighting and heating equipment, and fuel burned in a molten state, can solve the problem of insufficient research on the characteristics of biomass fuel, which affects the safe and economical operation of boilers, and the volatile content of biomass Advanced problems, to achieve the effect of compact structure, eliminating potential safety hazards, and improving fuel burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

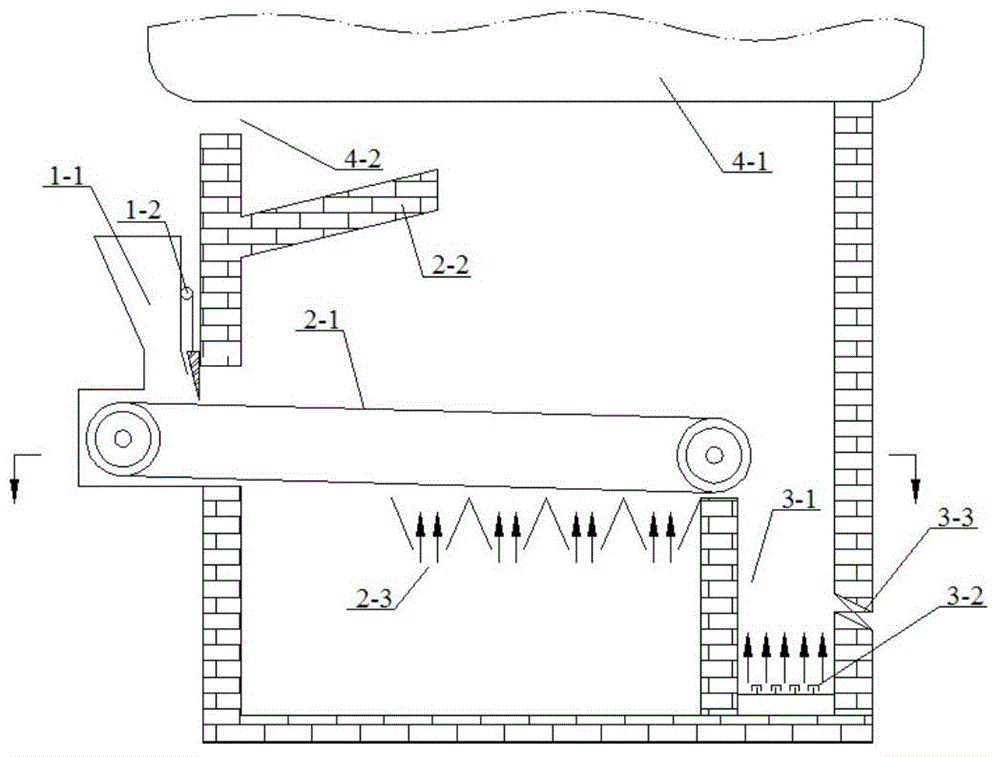

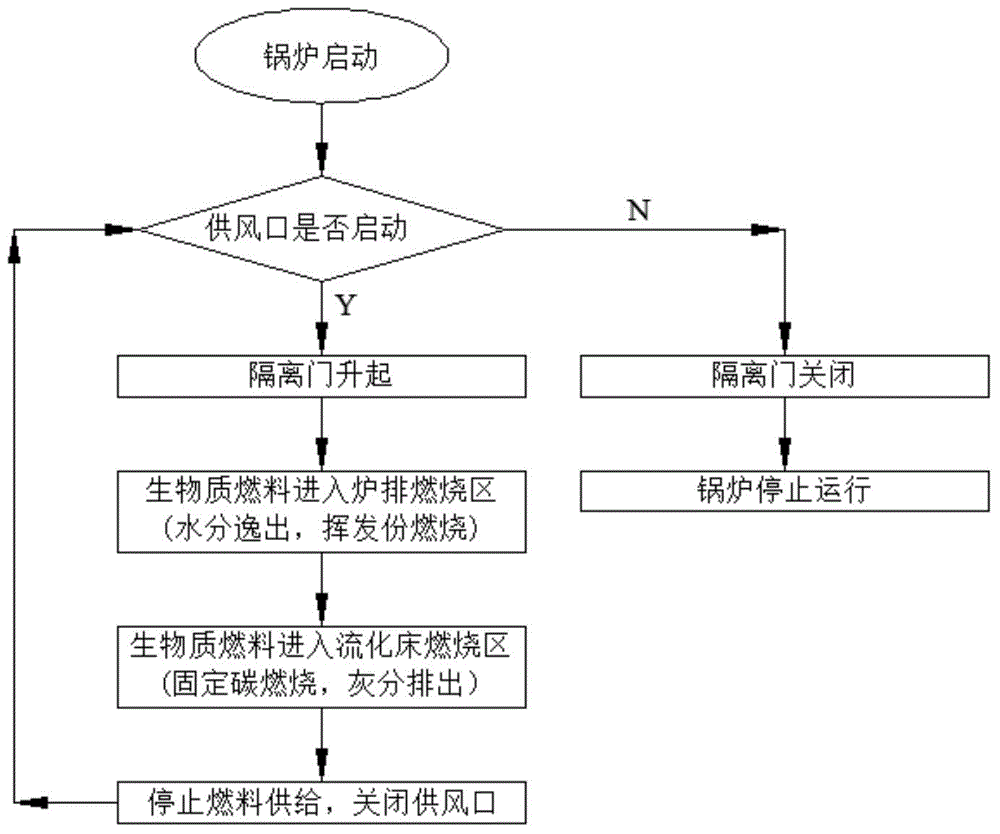

[0031] like figure 1 As shown, the biomass fuel falls into the fire grate from the feed hopper 1-1 and moves in the furnace along with the fire grate. After the air supply port is activated, the isolation door 1-2 rises so that the isolation door rises, and the biomass fuel can move forward into the furnace. When the air supply port is not activated, the isolation door descends under the action of gravity to close the isolation door, preventing further feeding of biomass fuel into the furnace. If the biomass fuel continues to be delivered to the furnace under the condition of insufficient air supply, the biomass fuel will escape volatile matter under the high-temperature radiation of the furnace, and the escaping volatile matter will accumulate in the furnace due to no combustion or insufficient combustion. It is easy to cause flashover accidents; therefore, the isolation door ensures that the biomass fuel is sent into the furnace only when there is air supply in the furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com