Silicone rubber cleaning and repairing agent and preparation method thereof

A technology of repairing agent and silicone rubber, which is applied in the direction of chemical instruments and methods, detergent compositions, non-surface active cleaning solvents, etc., to achieve the effect of penetration, high safety, and good volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

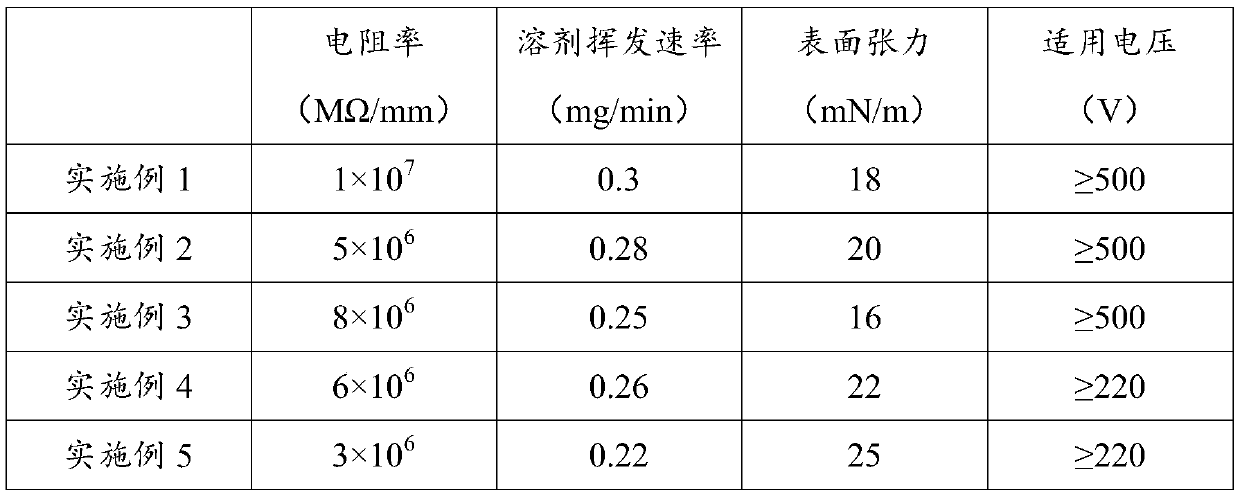

Examples

Embodiment 1

[0034] Silicone rubber cleaning and repairing agent is made of the following parts by weight: 7 parts of carboxyl silane coupling agent, 5 parts of octamethylcyclotetrasiloxane, Na 2 SiO 3 6 parts (particle size is 100nm), MgCl 2 10 parts (particle size is 100nm), 0.5 parts of nano-zinc oxide (particle size is 100nm), 0.25 parts of nano-magnesium oxide (particle size is 100nm), 2.75 parts of polydimethylsiloxane, 0.375 parts of acrylic acid, cerium nitrate 0.05 parts, 2.25 parts of nano-active calcium carbonate, 1.25 parts of vinyl siloxane, 0.55 parts of F-107, 450 parts of epoxy soybean oil.

[0035] The preparation method of silicone rubber cleaning repair agent, the steps are as follows:

[0036](1) 7 parts of carboxyl silane coupling agent, 5 parts of octamethylcyclotetrasiloxane, 0.55 part of F-107, 0.5 part of nano-zinc oxide (particle size is 100nm), 0.25 part of nano-magnesium oxide (particle size is 100nm), MgCl 2 10 parts (particle diameter is 100nm), 2.25 par...

Embodiment 2

[0042] Silicone rubber cleaning and repairing agent is made of the following parts by weight: 10 parts of epoxy silane coupling agent, 2 parts of octamethylcyclotetrasiloxane, Na 2 SiO 3 3 parts (particle size is 50nm), MgCl 2 15 parts (particle size is 100nm), 0.7 parts of nano-zirconia (particle size is 100nm), 0.3 parts of nano-titanium dioxide (particle size is 150nm), 3.6 parts of polydimethylsiloxane, 0.5 parts of acrylic acid, 0.02 parts of cerium nitrate 0.25 parts of nano-active calcium carbonate, 1.5 parts of vinyl siloxane, 0.2 parts of F-107, 450 parts of epoxy soybean oil.

[0043] The preparation method of silicone rubber cleaning repair agent, the steps are as follows:

[0044] (1) 10 parts of epoxy silane coupling agent, 2 parts of octamethylcyclotetrasiloxane, 0.2 parts of F-107, 0.7 parts of nano-zirconia (particle size is 100nm), 0.3 parts of nano-titanium dioxide (particle size is 150nm), MgCl 2 15 parts (particle size is 100nm), 0.25 part of nano-ac...

Embodiment 3

[0050] Silicone rubber cleaning and repairing agent is made of the following parts by weight: 5 parts of polyether silane coupling agent, 8 parts of octamethylcyclotetrasiloxane, Na 2 SiO 3 9 parts (particle size is 100nm), MgCl 2 8 parts (particle size is 50nm), 0.25 parts of nano-magnesium oxide (particle size is 200nm), 1.5 parts of polydimethylsiloxane, 0.15 parts of acrylic acid, 0.08 parts of cerium nitrate, 0.75 parts of nano-active calcium carbonate, vinyl 0.8 parts of siloxane, 0.8 parts of F-107, 450 parts of epoxy soybean oil.

[0051] The preparation method of silicone rubber cleaning repair agent, the steps are as follows:

[0052] (1) 5 parts of polyether silane coupling agent, 8 parts of octamethylcyclotetrasiloxane, 0.8 parts of F-107, 0.25 parts of nano-magnesium oxide (particle size is 200nm), 0.75 parts of nano-active calcium carbonate, MgCl 2 8 parts (particle size is 50nm), 0.8 parts of vinyl siloxane are added in the mixer and stirred evenly to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com