Wide-spectrum Shack-Hartmann wave-front sensor absolute calibration device and method

A calibration device and calibration method technology, applied in the field of optics, can solve the problem that the radius of curvature of the spherical wave to be measured is difficult to accurately measure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

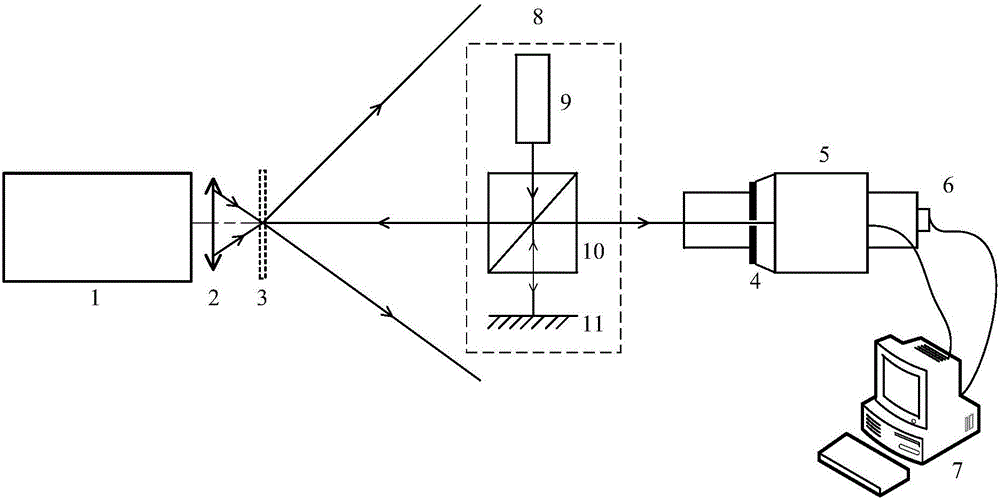

[0064] The technical solution adopted in the present invention is as follows

[0065] Such as figure 1 As shown, the present invention consists of a monochromator 1, a converging mirror 2, a point diffraction plate 3, an orifice plate 4, a Shaker-Hartmann wavefront sensor 5, a high-precision translation stage 6, an acquisition and control computer 7, and optical axis positioning It consists of 8 modules. The optical axis positioning module 8 is composed of a He-Ne laser 9 , a beam splitter 10 and a plane mirror 11 . The black solid line in the figure is the fixed device, and the dotted line is the replaceable device. The conical orifice plate is fixed on the front end of the Shaker-Hartmann wavefront sensor to be calibrated; the center of the conical hole of the conical orifice plate coincides with the center of the target surface of the Shaker-Hartmann wavefront sensor to be calibrated; the Xiaker-Hartmann wavefront sensor to be calibrated The K-Hartmann wavefront sensor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com