A kind of capacitive pressure sensor and preparation method thereof

A pressure sensor and capacitive technology, which is applied in fluid pressure measurement, instruments, and force measurement using capacitance changes, can solve the problems of poor mass production capacity and large capacitor volume, and achieve high Young's modulus, simplified circuits, Avoid the effects of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

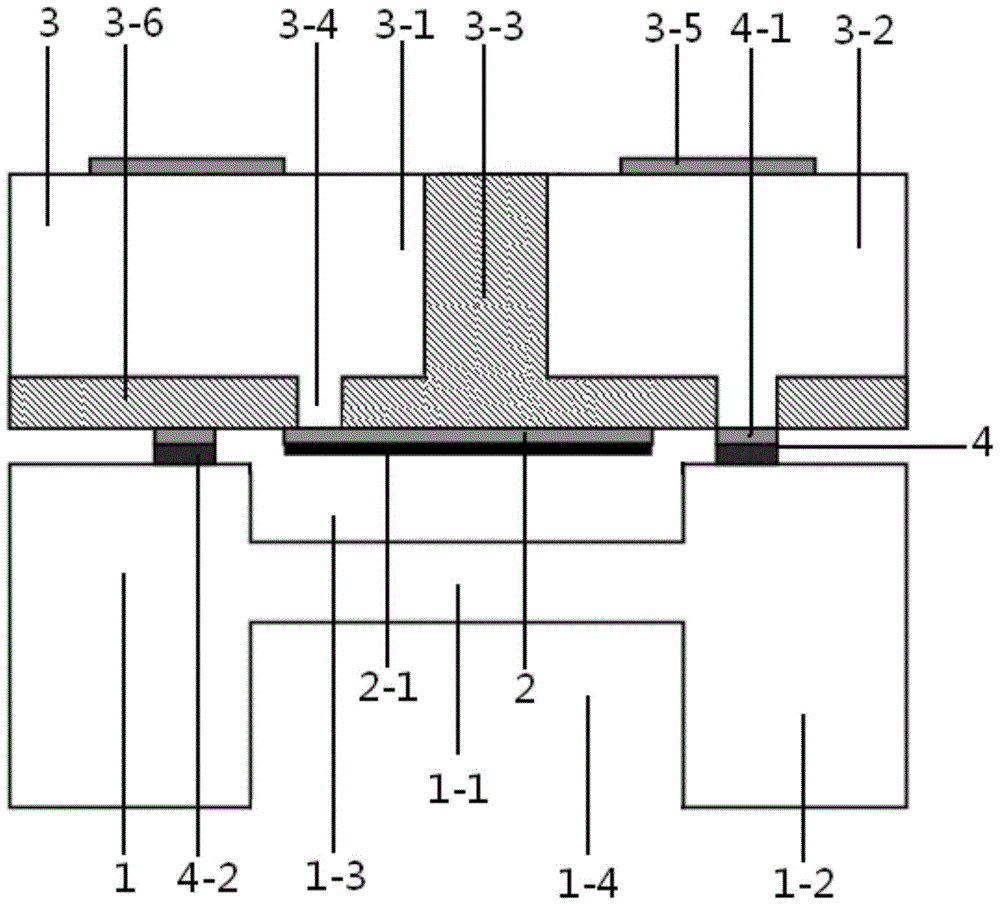

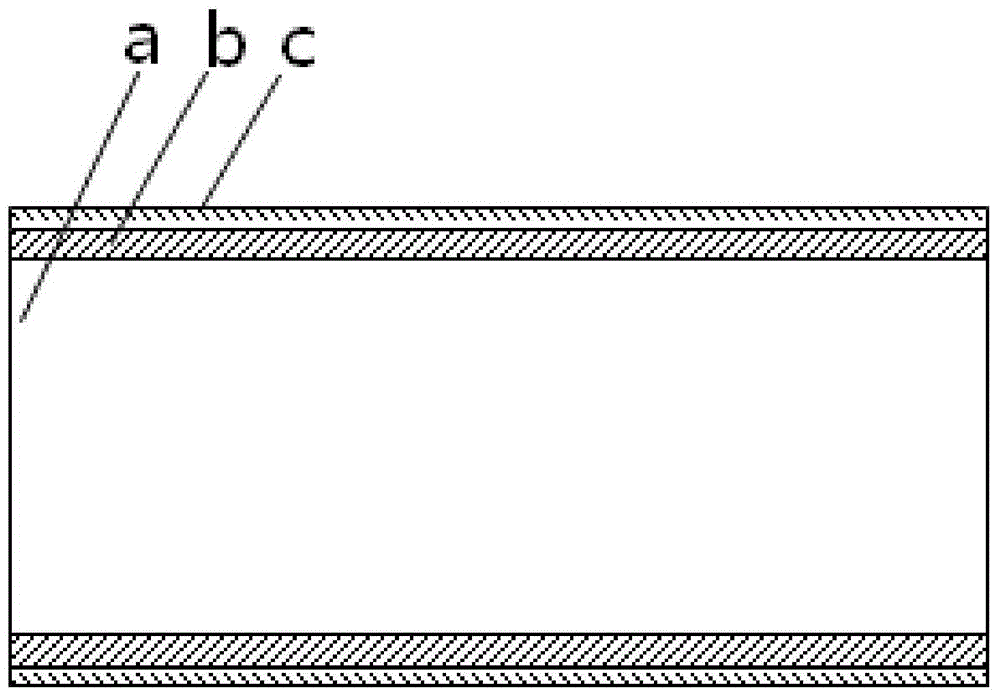

[0058] Such as figure 1 As shown, the capacitive pressure sensor of this embodiment includes a plate capacitance composed of a conductive monocrystalline silicon movable electrode plate 1 and a metal fixed electrode 2, and also includes a conductive monocrystalline silicon substrate 3 and a movable monocrystalline silicon substrate. The conductive support structure 4 between the electrode plate 1 and the conductive single crystal silicon base 3, the movable electrode plate 1 of the conductive single crystal silicon, the conductive single crystal silicon base 3 and the conductive support structure 4 form a closed chamber in the middle, and the metal The fixed electrode 2 is arranged on the conductive single crystal silicon substrate 3 inside the airtight chamber; the conductive single crystal silicon substrate 3 includes a plurality of conductive single crystal silicon blocks insulated from each other, each of the plurality of conductive single crystal silicon blocks All of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com