Rotary mechanical fault diagnosis method based on analytical modal decomposition

An analytical modal decomposition, rotating machinery technology, applied to vibration measurement in solids, testing of machine/structural components, and vibration measurement, etc., can solve problems affecting mechanical equipment performance, abnormal equipment vibration, equipment damage, etc., to achieve shortened Processing time, amplitude increase, effect of single frequency component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

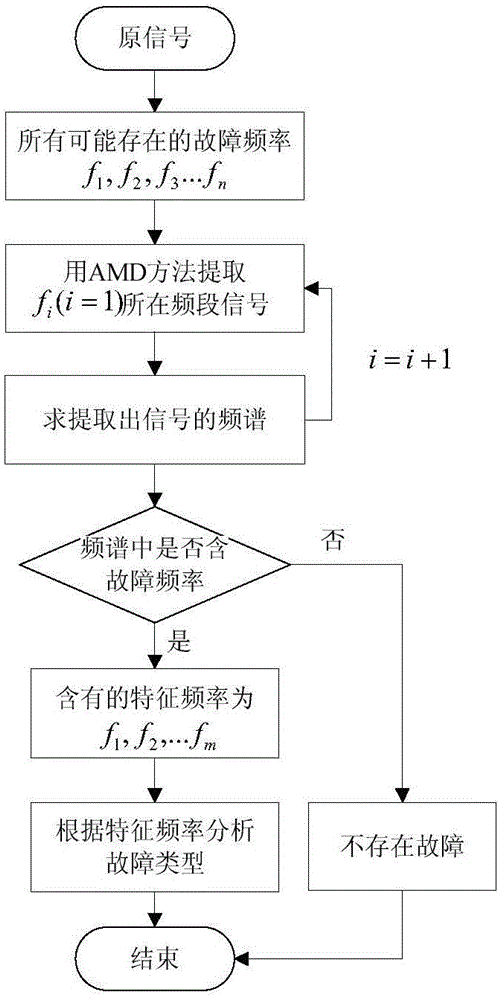

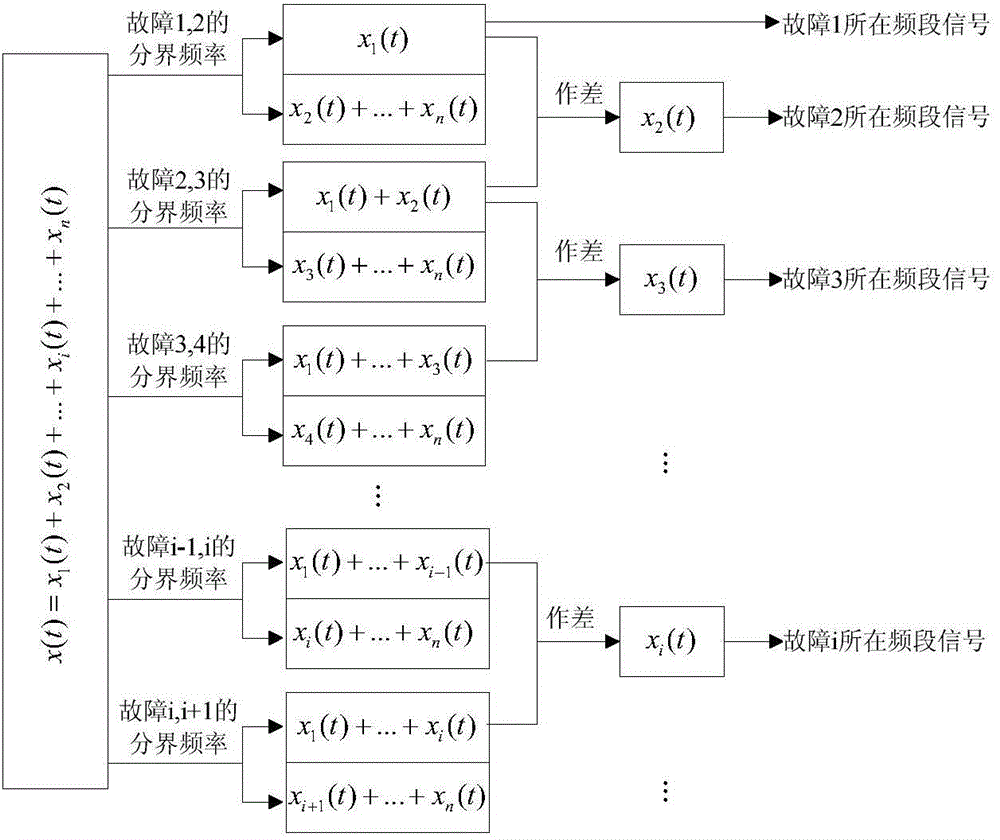

Method used

Image

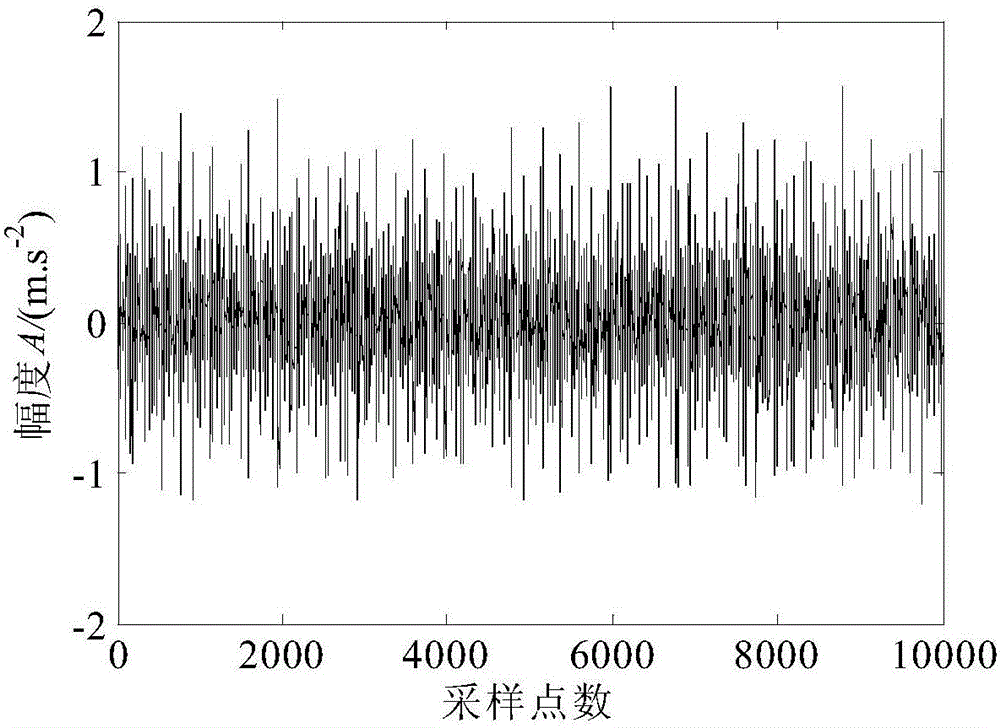

Examples

Embodiment 1

[0059] Rolling bearings are generally composed of inner rings, outer rings, rolling elements and cages. If a rolling bearing fails, its failure frequency is predictable. Assuming that the outer ring of the rolling bearing is fixed, the inner ring rotates with the working shaft, the rotating speed of the working shaft is N (r / min), the pitch diameter of the bearing is D (mm), the diameter of the rolling element is d (mm), and the contact angle is β (rad) , and the number of rolling elements is n, the characteristic frequencies of different faults are as follows:

[0060] Eigenfrequency when bearing outer ring is defective:

[0061] f o = nN 120 d ( 1 - d cos β D )

[0062] Eigenfrequency when bearing inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com