Efficient drying treating system for sample gas

A drying treatment and high-efficiency technology, applied in the field of high-efficiency drying and treatment systems for sample gas, can solve the problems of complex structure and uneconomical, and achieve the effect of expanding the injection volume, simple structure, and improving sensitivity and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

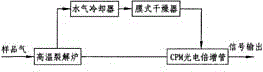

[0015] Embodiment: A high-efficiency drying treatment system for sample gas, said system is composed of a high-temperature cracking furnace, a water-gas cooler, a membrane dryer and a CPM photomultiplier tube connected in sequence. Wherein, the membrane dryer has built-in nanofiber bundles, and sealing plugs are provided at both ends of the nanofiber bundles. The water-air cooler adopts a semiconductor cooling module. The semiconductor cooling module has a built-in gas-liquid separator surrounded by insulation materials. The center of the left side of the gas-liquid separator is equipped with a semiconductor cooling device. There is an exhaust fan for cooling. A biofilter is also provided between the high temperature cracking furnace and the water-air cooler, the upper end of the biofilter is provided with a feeding port, the lower end of the biofilter is provided with a discharge port, and the biofilter is filtered by nano photocatalysis. device and activated carbon layer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com