Anode flow field plate of methanol fuel cell

A methanol fuel cell and anode flow field technology, applied in fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of large volume and low fuel utilization rate, achieve high structural strength, improve fuel utilization rate, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

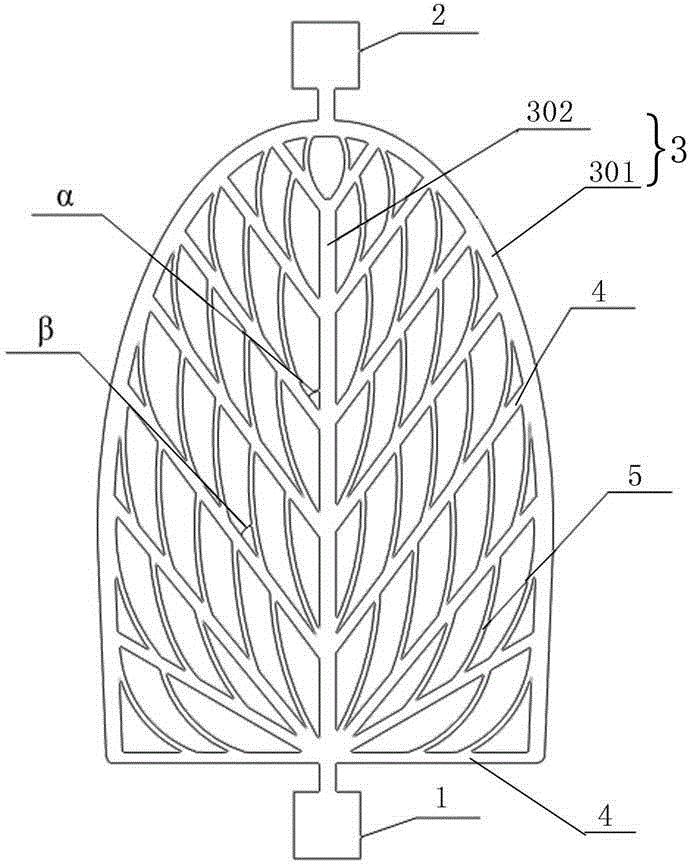

[0018] Using the disclosed MEMS technology, the anode flow field plate channel with a depth of 100 μm is etched on the silicon base structure. According to the vein structure of leaves in nature, three levels of flow channels were designed. The diameter of the primary flow channel 3 is 200 μm, the diameter of the secondary flow channel 4 is 160 μm, and the diameter of the third level flow channel 5 is 120 μm.

[0019] The primary flow channel includes an outer flow channel 301 and an intermediate flow channel 302 , the intermediate flow channel 302 is arranged along the center line of the outer flow channel 301 , and the feed port 1 is connected to the front end of the intermediate flow channel 302 . The outer flow channel 301 is a semi-elliptical structure, and the discharge port 2 is set on the top of the semi-elliptical structure. The size of feed port 1 and discharge port 2 is 1x1mm.

[0020] A number of linear secondary flow channels 4 are symmetrically arranged on both ...

Embodiment 2

[0023] The difference from Example 1 is that SU-8 is used as the flow field plate material, and the anode flow field plate channel with a depth of 200 μm is etched on the substrate of this material. The diameter of the primary flow channel is 200 μm, the diameter of the secondary flow channel 4 is 140 μm, and the diameter of the tertiary flow channel 5 is 98 μm.

Embodiment 3

[0025] The difference from Example 1 is that PDMS glue is used as the material of the flow field plate, and the anode flow field plate channel with a depth of 150 μm is etched on the substrate of the material. The diameter of the primary flow channel is 200 μm, the diameter of the secondary flow channel 4 is 160 μm, and the diameter of the tertiary flow channel 5 is 128 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com