Method for thermal runaway protection of power battery pack by virtue of heat pipe technology

A power battery pack and thermal runaway technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as inability to isolate a single cell, damage to thermal runaway cell modules, and safety hazards for drivers and passengers. , to achieve the effect of simple structure, delaying cell fire, and facilitating engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

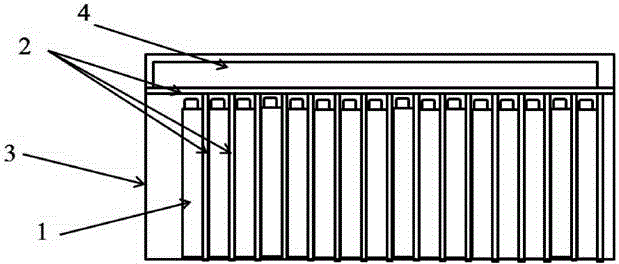

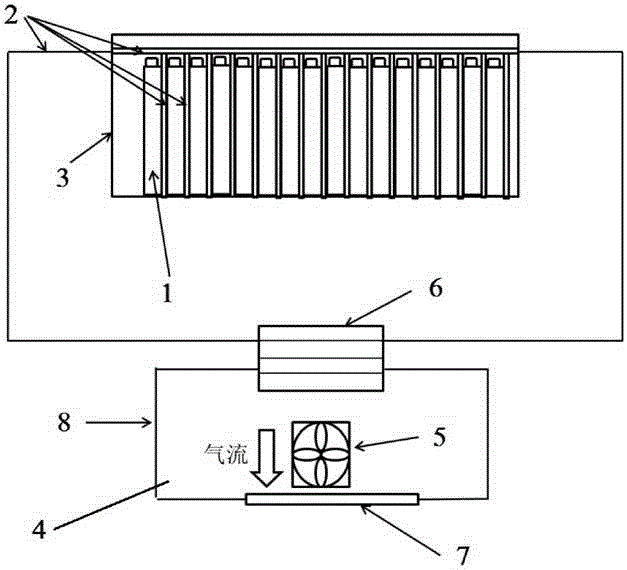

[0028] The heat pipe is connected with the heat dissipation fins, and a fan can be installed on the box body at a position equivalent to the height of the heat dissipation fins. When the fan is turned on, forced convection can be formed on the surface of the heat dissipation fins to enhance the heat dissipation effect. The fan can adopt two forms of blowing or sucking, and the air outlet (inlet) is on the side opposite to the fan on the surface of the box. If there is no fan, the heat is dissipated through the natural convection between the fins and the external environment. The second part of the heat pipe and the box form an airtight battery compartment, which can seal the battery module in the battery compartment to ensure the protection level of the space where the battery module is located in the box.

[0029] The heat pipe inside the box is connected to the heat pipe outside the box, and the heat pipe outside the box is connected to the external heat exchanger. radiator...

Embodiment 2

[0031] Use heat pipe technology to realize the protection of power battery pack cells from thermal runaway;

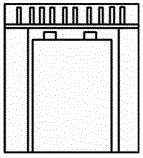

[0032] The heat pipe consists of 2 to 3 parts. The first part of the heat pipe is inserted into the gap of the electric core, the second part of the heat pipe connects the first part of the heat pipe and the cooling fins, or the second part of the heat pipe connects the first part of the heat pipe and the third part of the heat pipe, and the third part Part of the heat pipe is connected to the heat exchanger outside the battery box;

[0033] The cooling fins can be dissipated by forced air cooling, or by heat pipes and heat exchangers;

[0034] If forced air cooling is used to dissipate heat from the cooling fins, the box body and the second part of the heat pipe form a sealed battery compartment to ensure the protection level of the battery compartment;

[0035] If the heat is dissipated through the heat exchanger, the battery box is a closed battery compartment to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com