Polycarboxylic acid resin and epoxy resin composition

A polybasic carboxylic acid and epoxy resin technology, applied in the direction of electrical components, circuits, electrical solid devices, etc., can solve the problems of cured product characteristic deviation, difficult to withstand long-term lighting, peeling, etc., to achieve improved operability, excellent transparency, Excellent light fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

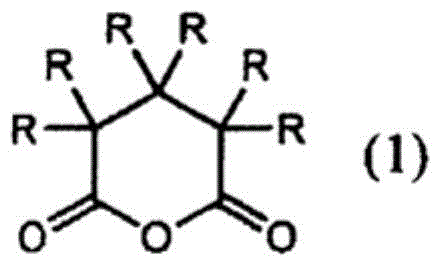

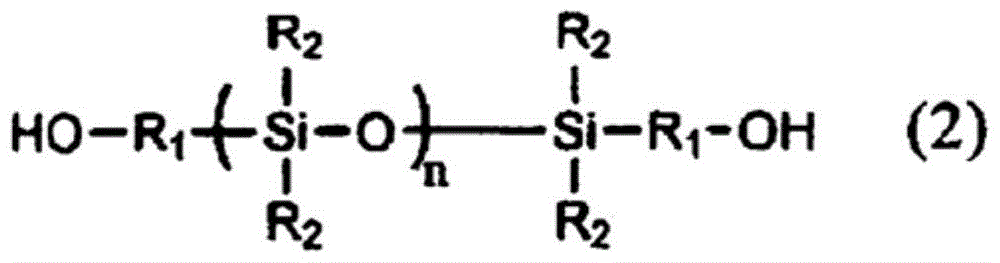

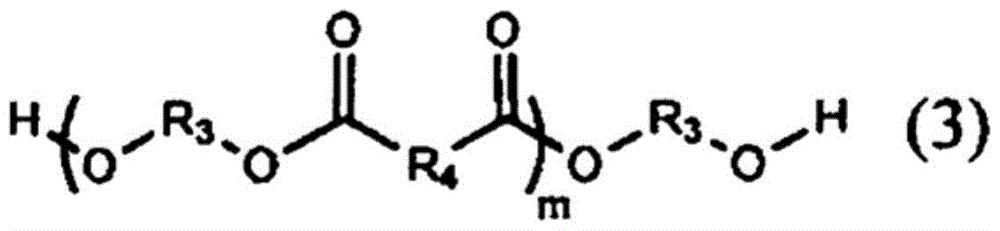

[0194] Into a flask equipped with a stirring device, a condenser, and a thermometer, 58.8 parts of methanol-modified polysiloxane X22-160AS (manufactured by Shin-Etsu Chemical Co., Ltd.) at both ends, tricyclodecane dimethanol (manufactured by TCD Alcohol DM OXEA) ) and 33.9 parts of 2,4-diethylglutaric anhydride (YH-1120 manufactured by Mitsubishi Chemical Corporation), were reacted at 100°C for 8 hours, at 120°C for 4 hours, and at 140°C for 1 hour to obtain 99 parts of polyhydric carboxylic acid resin (A-1) of this invention. The acid value of the obtained compound was 123 mgKOH / g, the viscosity was 988 mPa·s, and the appearance was a colorless transparent liquid.

Embodiment 2

[0196]Into a flask equipped with a stirring device, a condenser, and a thermometer, 58.8 parts of methanol-modified polysiloxane X22-160AS (manufactured by Shin-Etsu Chemical Co., Ltd.) at both ends, 2,4-diethyl-1,5- 6.4 parts of pentanediol (Kyowajiol PD-9 manufactured by Kyowa Hakka Chemical Co., Ltd.), 34.8 parts of 2,4-diethylglutaric anhydride (YH-1120 manufactured by Mitsubishi Chemical Co., Ltd.), reacted at 100°C for 10 hours, and reacted at 120°C It reacted for 2 hours, and obtained 99 parts of polyhydric carboxylic acid resin (A-2) of this invention. The acid value of the obtained compound was 120 mgKOH / g, the viscosity was 532 mPa·s, and the appearance was a colorless transparent liquid.

Embodiment 3

[0198] Into a flask equipped with a stirring device, a condenser, and a thermometer, 58.8 parts of methanol-modified polysiloxane X22-160AS (manufactured by Shin-Etsu Chemical Co., Ltd.) at both ends, ditrimethylolpropane (Di-TMP Hiroei 5.4 parts of Perstorp Co., Ltd., 35.9 parts of 2,4-diethylglutaric anhydride (YH-1120, manufactured by Mitsubishi Chemical Corporation), reacted at 100° C. for 8 hours, and reacted at 120° C. for 10 hours. It was made to react at 140 degreeC for 2 hours, and 99 parts of polyvalent carboxylic acid resin (A-3) of this invention were obtained. The acid value of the obtained compound was 118 mgKOH / g, the viscosity was 1229 mPa·s, and the appearance was a colorless transparent liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com