Internal clamp

An internal counterpart and integrated technology, applied in auxiliary devices, gas/liquid distribution and storage, applications, etc., can solve the problems of unsatisfactory welding conditions and long axial length, etc., to reduce size and shorten axial length , good calibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in conjunction with accompanying drawing and specific embodiment:

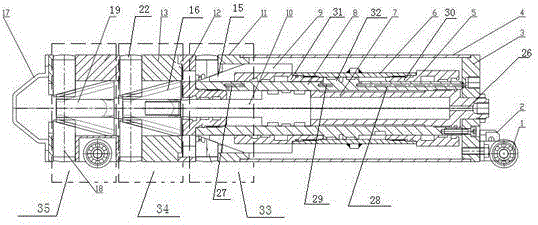

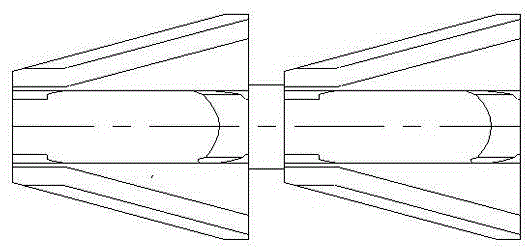

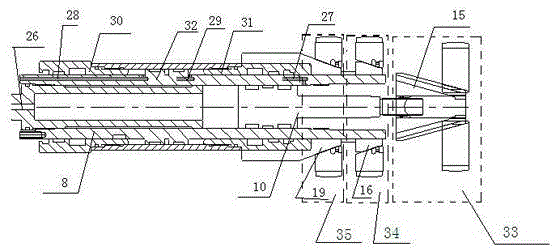

[0025] Such as figure 1 As shown, a short pipe joint internal counterpart, said internal counterpart includes a frame, tensioning mechanism I33, tensioning mechanism II34, tensioning mechanism III35, traveling wheel II25 and traveling wheel I1; said machine The frame includes a base 3 and an outer cover 4; the base 3 is provided with a pull ring 2, which is used for hanging wire rope traction equipment during the welding process, and is screwed on the base 3, and can also be directly welded or made into an integral structure with the base 3 ; The tensioning mechanism I33, tensioning mechanism II34, and tensioning mechanism III35 are coaxially arranged and arranged adjacent to each other in the axial direction; the tensioning mechanism II34 and tensioning mechanism III35 are a group, and they are located in the same In the pipeline; the tension mechanism II34 and tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com