Device and technology for manufacturing prefabricated components of curved-surface cement products for building

A technology for cement products and construction, which is applied in the field of devices for manufacturing curved cement product pre-components for construction. It can solve the problems of inability to meet the original design requirements and construction progress, high labor intensity, rough surface quality of products, etc., and achieve wood saving. Mold and metal mold resources, engineering construction cost reduction, accurate effect of curved surface formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention provides a device and process for manufacturing curved surface cement product pre-components for construction. The specific implementation methods are introduced as follows in combination with the drawings in the description:

[0035] like Figure 1a-Figure 1d As shown, the traditional curved surface cement board products for construction are all made by manual pouring of wooden models or machine-added metal molds. The specific manufacturing steps of this method are as follows:

[0036] like Figure 1a As shown, step one: prepare wood / metal blank;

[0037] like Figure 1b As shown, step 2: milling the model cavity to form a wooden / metal mold 6;

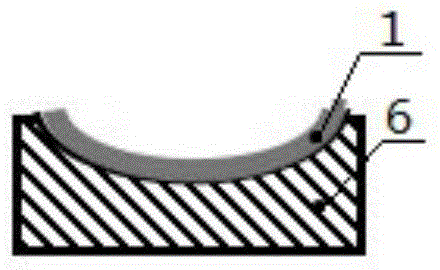

[0038] like Figure 1c As shown, step 3: manually pour and spread the cement slurry in the wooden / metal mold 6;

[0039] like Figure 1d As shown, Step 4: demoulding and trimming the finished product.

[0040] Concerning the shortcomings of the traditional production process of curved cement board products f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com