Microwave mixing heating and pressing device

A pressurization device and microwave technology, applied in the field of hybrid heating and pressurization equipment, can solve the problems of inability to maintain the uniformity of the temperature field in the curing process of composite components, reverse external temperature difference, and fast external heat dissipation, so as to ensure the quality of finished products and reduce The effect of temperature difference between inside and outside to ensure the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

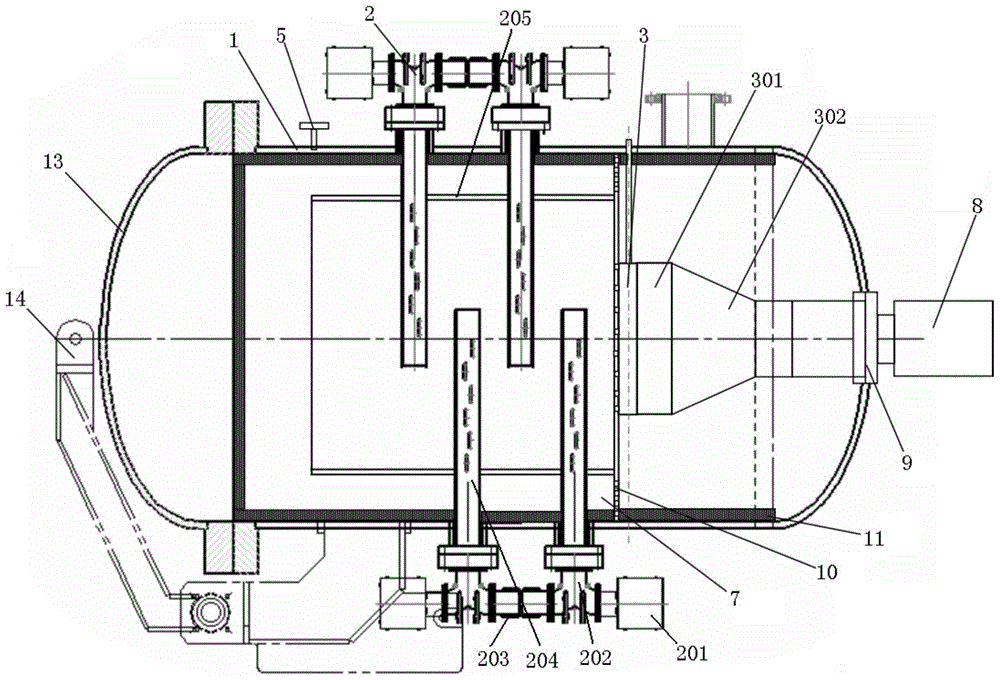

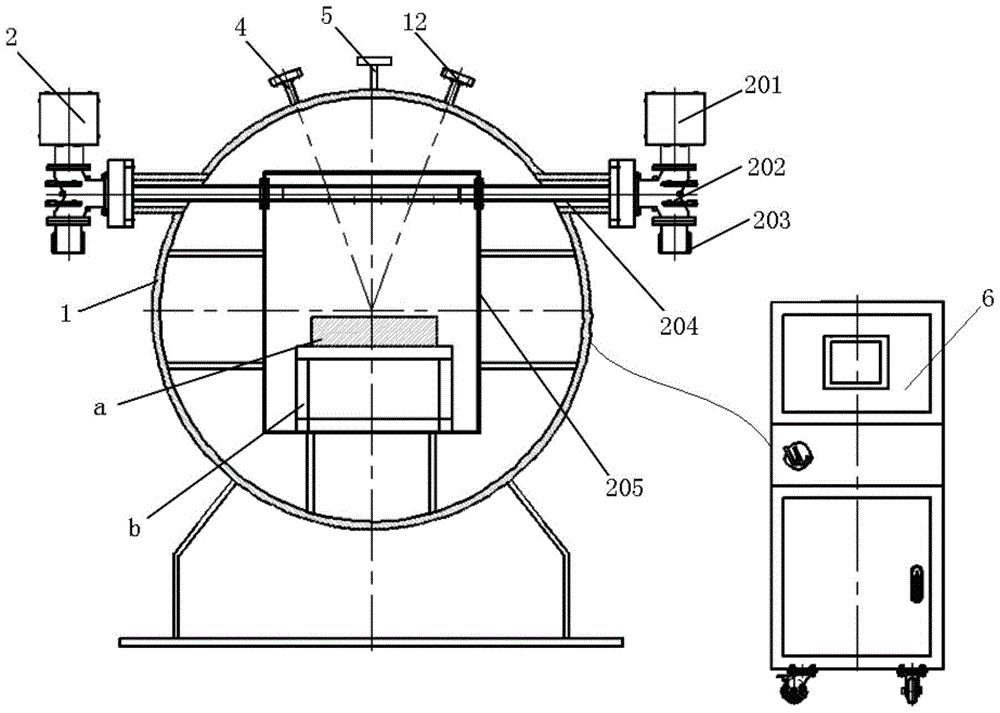

[0027] figure 1 It is one of the structural schematic diagrams of the microwave mixing heating and pressing device in the preferred embodiment of the present invention; figure 2 It is the second structural diagram of the microwave mixing heating and pressing device in the preferred embodiment of the present invention.

[0028] like figure 1 and figure 2As shown, the microwave mixing heating and pressurizing device of this embodiment includes a tank body 1, and the tank body 1 is provided with a microwave generator for feeding microwaves into the inner cavity of the tank body 1 and making the materials in the tank body 1 generate self-heating. 2. A fluid auxiliary temperature regulating device 3 for feeding auxiliary temperature regulating fluid into the inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com