Chemical pretreatment method and device thereof for treating high-salinity wastewater

A pretreatment device and high-salt technology, which is applied in the field of water treatment, can solve the problems of large consumption of chemicals, easy dust pollution in the surrounding environment, and difficulty in controlling the dosage of chemicals, and achieves complete reaction, high hardness removal efficiency, and economical savings. The effect of drug cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

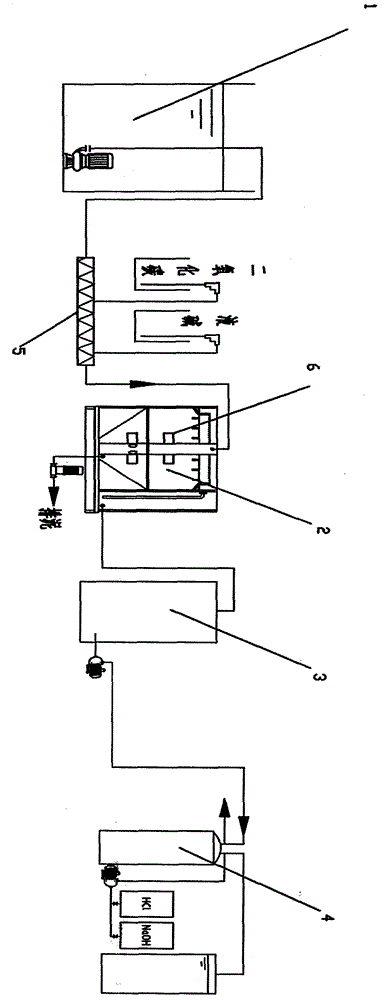

[0033] In conjunction with accompanying drawing, the present invention is described further:

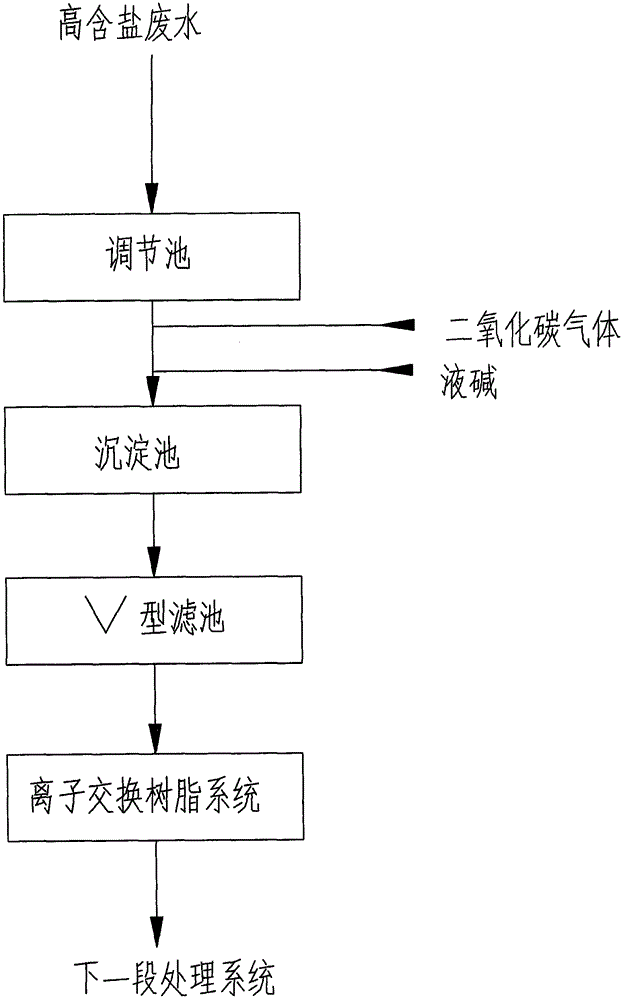

[0034] like figure 1 and figure 2 As shown, the following takes the industrial park saline wastewater treatment project as an example to introduce.

[0035] A chemical pretreatment device for treating high-salt wastewater, comprising: a regulating tank 1, a pipeline mixer 5, a sedimentation tank 2, a V-shaped filter tank 3 and an ion exchange resin 4, wherein:

[0036] Regulating pool 1 collects high-salt wastewater in the industrial park through pipelines;

[0037] The pipeline mixer 5 is installed on the connecting pipeline between the regulating tank 1 and the sedimentation tank 2. One end of the pipeline mixer 5 communicates with the output pipeline of the regulating tank 1 through a pipeline, and the other end communicates with the water inlet pipeline of the sedimentation tank 2. The pipeline The mixer 5 is provided with an air inlet pipe and a medicine feeding pipe;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com