Design method for property balance of high viscosity and high elastic stress dissipative materials

A stress-dissipating, high-viscosity technology, applied in the field of road asphalt pavement material manufacturing, can solve problems such as low service life and impact, and achieve reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A new type of high-viscosity and high-elastic stress dissipation material is composed of the following components according to the mass ratio: high-viscosity asphalt binder: aggregate: polyester fiber = 7 ~ 11: 100: 0.03; the aggregate has a particle size of 5 ~ 8mm basalt, machine-made sand with a particle size of 3-5mm, natural sand and mineral powder are composed according to a certain ratio; the aggregate ratio is 8:60:29:3.

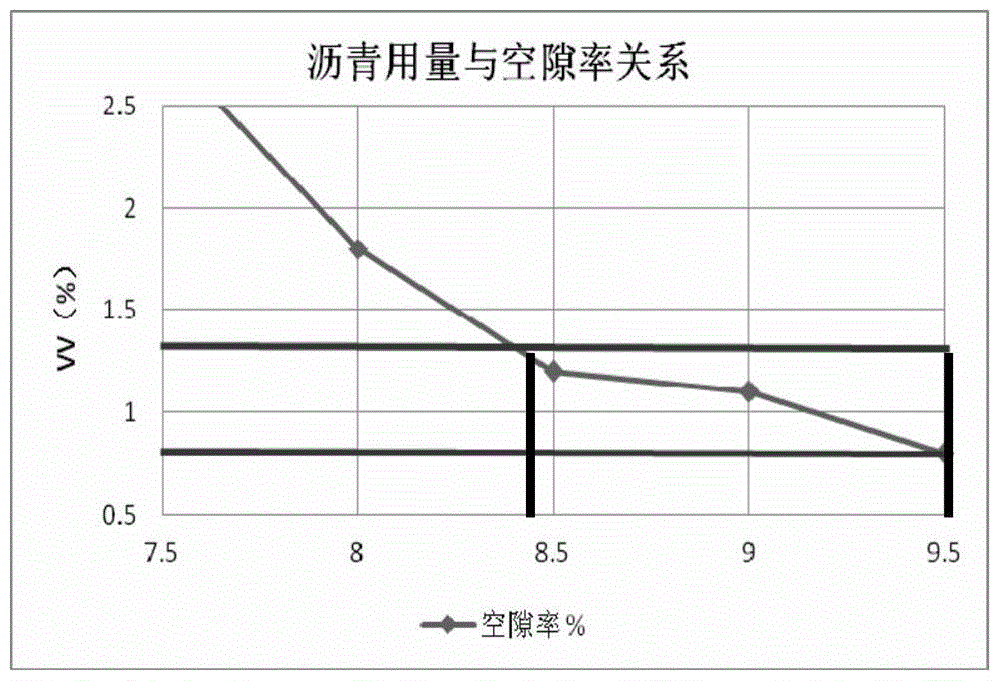

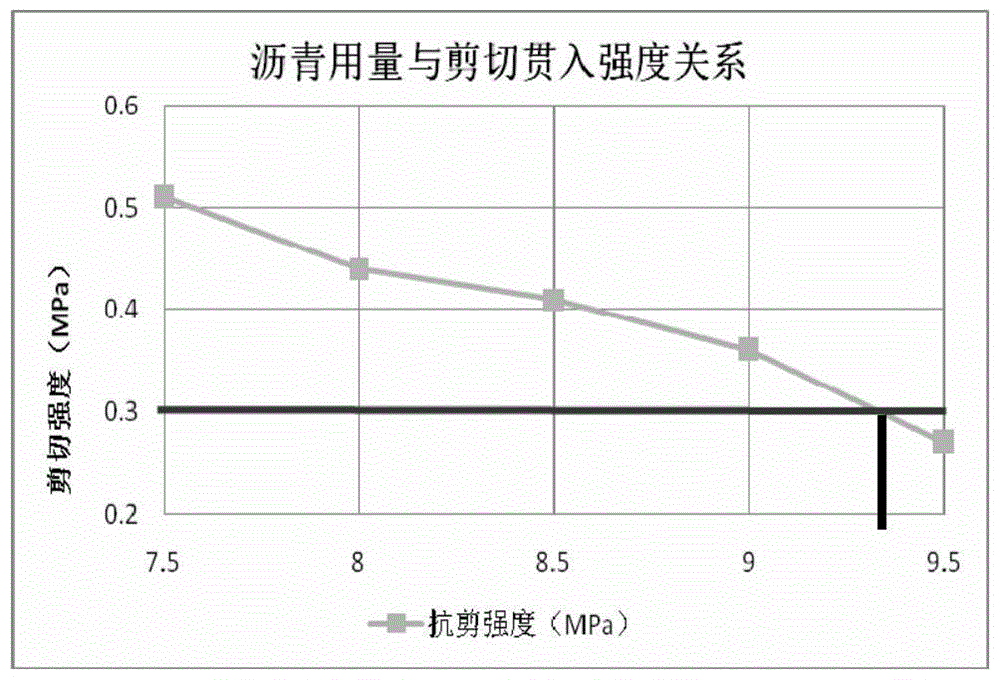

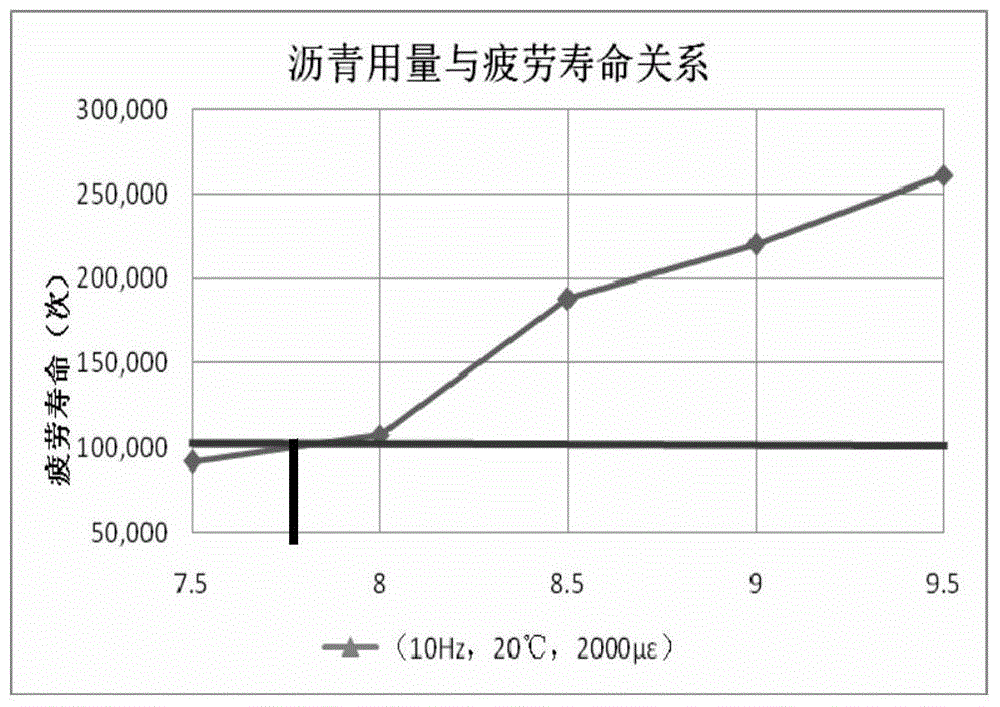

[0035] Estimate the appropriate asphalt content OAC of asphalt mixture based on engineering experience 0 , the estimation method is the same as the method for determining the asphalt ratio of hot mix asphalt mixture, the estimated asphalt dosage is 8.5%, and the volume index and Performance index, according to the range requirements of the volume index and performance index, comprehensively determine the optimal amount of asphalt. Among them, the volume index needs to measure the porosity when the number of rotary compaction is 100 times, and t...

Embodiment 2

[0050] A new type of high-viscosity and high-elastic stress dissipation material is composed of the following components according to the mass ratio: high-viscosity asphalt binder: aggregate: polyester fiber = 7 ~ 11: 100: 0.03; the aggregate has a particle size of 5 ~ 8mm basalt, machine-made sand with a particle size of 3-5mm, natural sand and mineral powder are composed according to a certain ratio; the aggregate ratio is 9:59:30:2.

[0051] Estimate the appropriate asphalt content OAC of asphalt mixture based on engineering experience 0 , the estimation method is the same as the method for determining the asphalt ratio of hot mix asphalt mixture, the estimated asphalt dosage is 8.5%, and the volume index and Performance index, according to the range requirements of the volume index and performance index, comprehensively determine the optimal amount of asphalt. Among them, the volume index needs to measure the porosity when the number of rotary compaction is 100 times, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com