Thermoplastic water-swellable elastomer and preparing method and application thereof

A water-swelling and elastic body technology, which is applied in chemical instruments and methods, and other chemical processes, can solve problems such as the fields that limit the application of water-swelling rubber, the decline in mechanical properties, and the degradation of product performance, and achieve good batch preparation feasibility, Ease of processing and good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

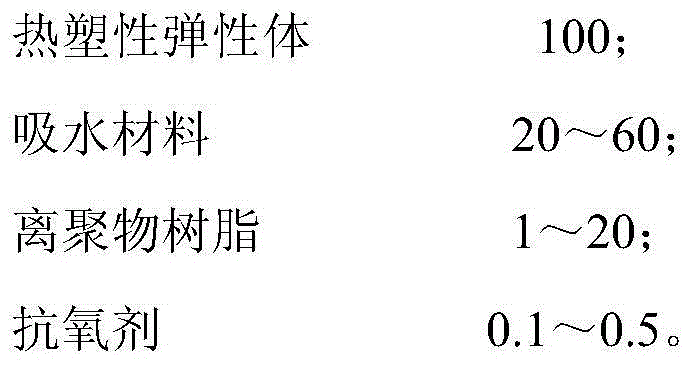

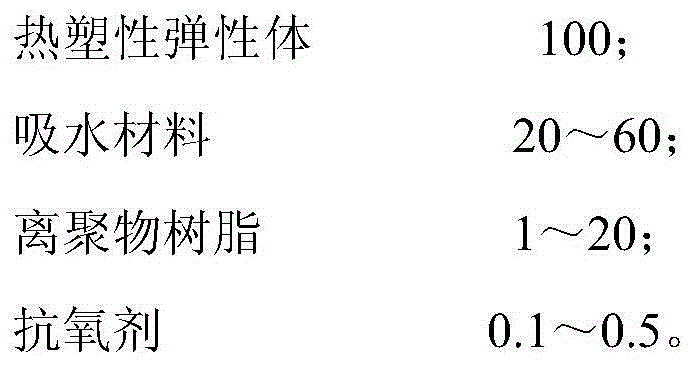

Method used

Image

Examples

Embodiment 1

[0022] (1) Before the experiment, 100 parts by weight of thermoplastic elastomer, 30 parts by weight of sodium polyacrylate water-absorbing material and 5 parts by weight Bake W 501NC ionomer resin at 90°C for 4 hours.

[0023] (2) At room temperature, 100 parts by weight of thermoplastic elastomer and 0.5 part by weight of antioxidant were mixed in a high-speed mixer for 5 minutes at a speed of 800 rpm to obtain an initial mixture.

[0024] (3) The premix was then added to an internal mixer at 180°C for 20 minutes of melt mastication, followed by adding 5 parts by weight of ionomer resin W 501NC melted and sheared for 10 minutes; finally added 30 parts by weight of sodium polyacrylate and kneaded for 15 minutes to obtain a kneaded product; the kneaded product was added to a single-screw extruder again for secondary plasticization and cooling and cutting pellets at a temperature of 180° C. and a rotational speed of 60 rpm to obtain a high-performance thermoplastic water-swe...

Embodiment 2

[0037] (1) Before the experiment, 100 parts by weight of thermoplastic elastomer, 30 parts of sodium polyacrylate water-absorbing material and 7 parts Bake W 501NC ionomer resin at 90°C for 4 hours.

[0038] (2) At room temperature, 100 parts by weight of thermoplastic elastomer and 0.5 part by weight of antioxidant were mixed in a high-speed mixer for 5 minutes at a speed of 900 rpm to obtain an initial mixture.

[0039] (3) Then add the premix into the internal mixer at 180°C for 20 minutes of melt mastication, then add 7 parts of ionomer resin AMPLIFY IO 3701 for 10 minutes of melt shearing; finally add sodium polyacrylate 30 Parts by weight, mixed for 15 minutes to obtain a mixed rubber; the mixed product was added to the single-screw extruder again for secondary plasticization and cooling and pelletizing, the temperature was 180 ° C, and the rotational speed was 60 rpm to obtain high-performance thermoplastic Water-swellable elastomer.

[0040](4) Inject the sample str...

Embodiment 3

[0051] (1) Before the experiment, 100 parts by weight of thermoplastic elastomer, 30 parts of sodium polyacrylate water-absorbing material and 10 parts Bake W 501NC ionomer resin at 90°C for 4 hours.

[0052] (2) At room temperature, 100 parts by weight of thermoplastic elastomer and 0.5 part by weight of antioxidant were mixed in a high-speed mixer for 5 minutes at a speed of 1000 rpm to obtain a primary mixture.

[0053] (3) Then add the premix into the internal mixer at 195°C for 20 minutes of melt mastication, then add 10 parts of ionomer resin AClyn for 10 minutes of melt shearing; finally add 30 parts by weight of sodium polyacrylate , mixed for 15 minutes to obtain a mixed rubber; the mixed product was added to the single-screw extruder again for secondary plasticization and cooled and pelletized at a temperature of 190 ° C and a rotational speed of 60 rpm to prepare a high-performance thermoplastic water expandable elastomer.

[0054] (4) Inject the sample strips fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| draft ratio | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com