Process for lifting asphalt pavement inspection well and lifting structure

An asphalt pavement and inspection well technology, which is applied to underwater structures, infrastructure engineering, roads, etc., can solve the problems of asphalt concrete cracking, shortening the service life, affecting the appearance, etc. cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

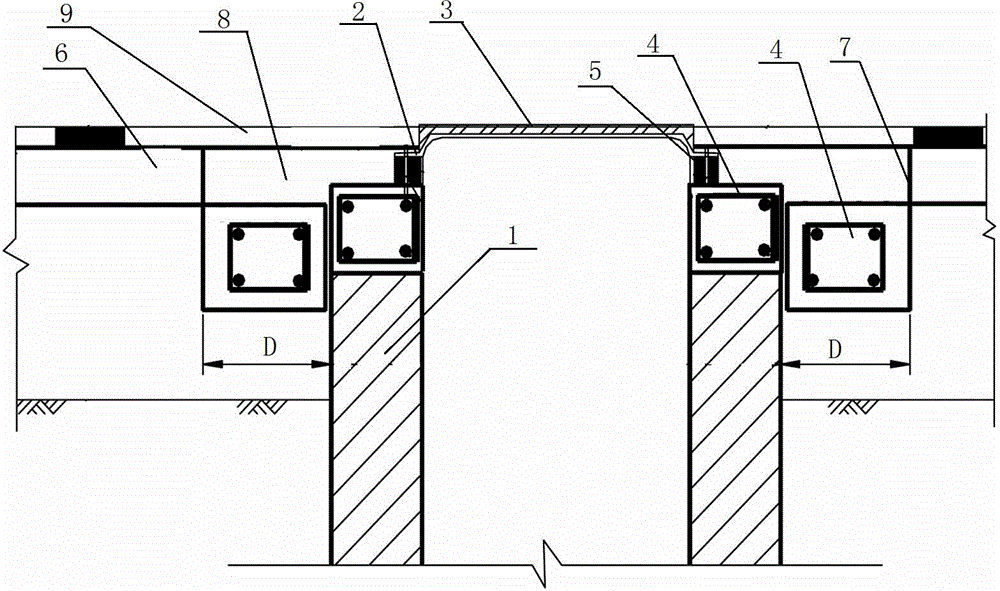

[0031] A process for lifting an asphalt pavement inspection well, characterized in that the specific steps are:

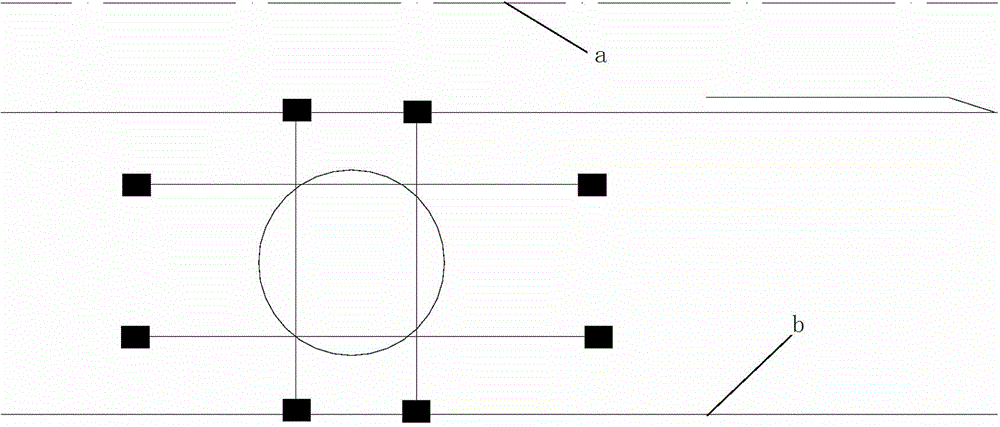

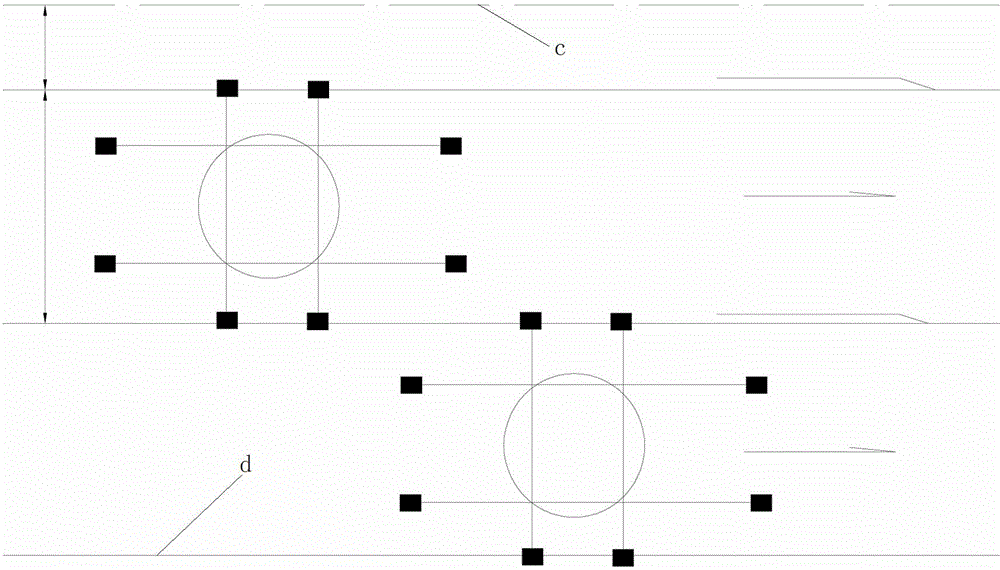

[0032] 1) Use a steel plate to cover and fix the wellhead of the inspection well, pave the underlayer of asphalt concrete on the road surface of the inspection well to be lifted, and remove the underlayer of asphalt concrete above and around the inspection well in reverse, remove the steel plate, and make the inspection well A circular groove is left between the periphery and the lower layer of asphalt concrete;

[0033] 2) Clean the circular groove, then place the steel keel, and pre-fix the well seat according to the height of the well seat, and then set up the inner mold in the inspection well, and finally install it in the circular groove Pour fine stone quick-hardening high-strength concrete until it is flush with the lower layer of asphalt concrete, so as to completely cover the entire well base, and maintain it to standard strength;

[0034] 3) Brush a laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com