Determination method for interface heat transfer coefficient in casting process

A technology of interface heat transfer coefficient and measurement method, applied in the direction of material thermal development, etc., can solve the problem that the interface heat transfer coefficient is difficult to determine accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

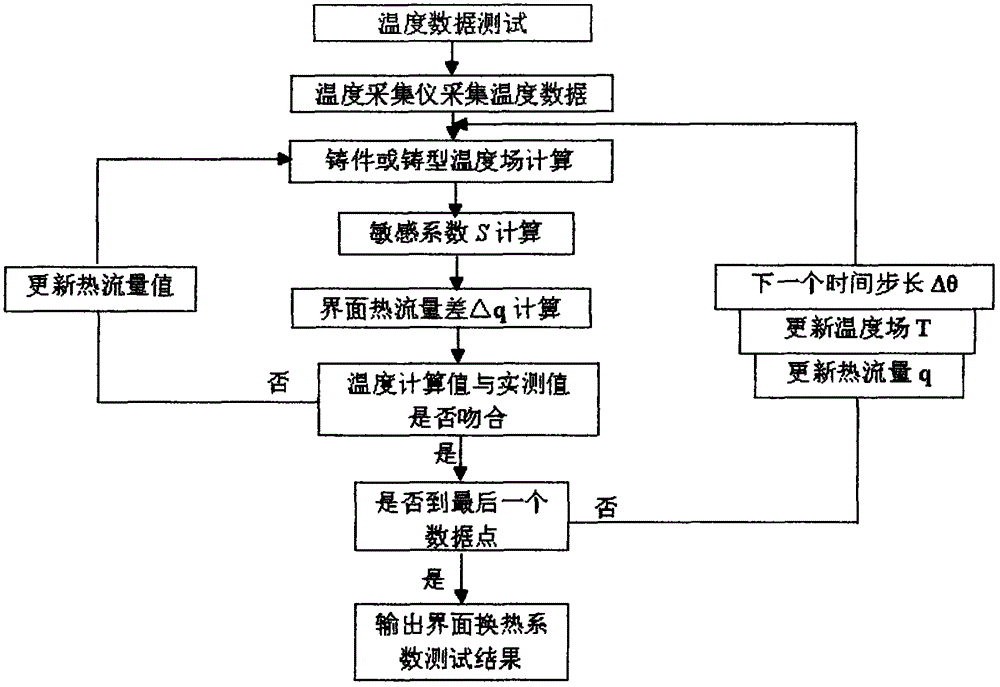

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

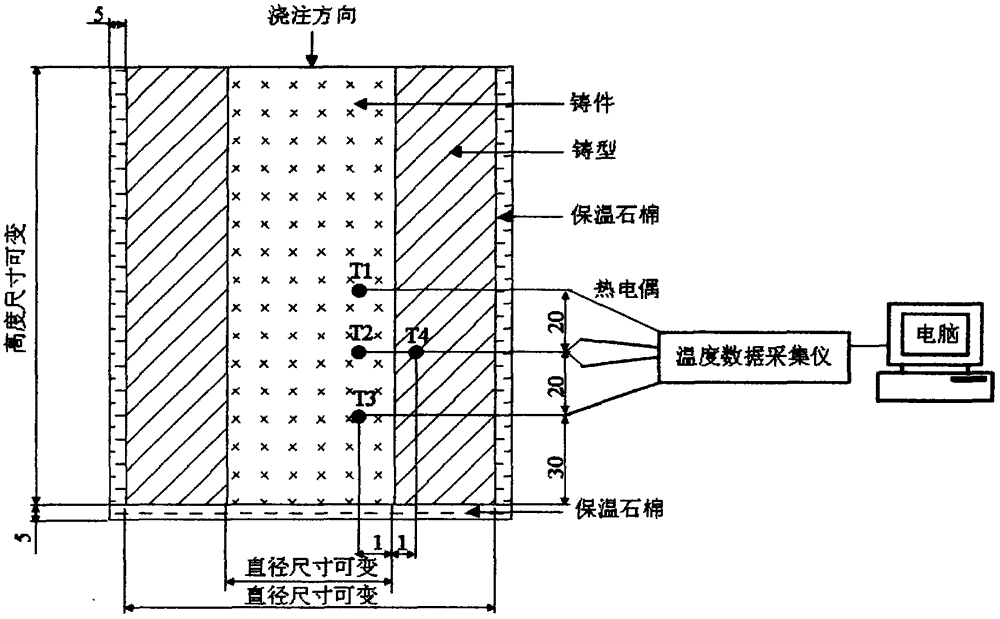

[0041] The present invention is applied in gray cast iron lost foam casting experiment, and the position that thermocouple is placed in experiment process is as follows figure 2 as shown, figure 2 In T1, T2 and T3 are the positions of temperature measurement during the experiment, respectively. In the experiment scheme, the initial mold temperature is 25°C, and the pouring temperature during the experiment is 1350°C. Considering that during lost foam casting, when the foam encounters molten metal, the gas generated by combustion will escape through the pores of the sand mold, and the asbestos used for heat insulation was removed from the outer surface of the mold during the experiment. In the casting experiment plan, the thickness of the castings is 50mm and 70mm respectively, while the thickness of the mold is 80mm, and the time interval of data collection is 0.2 seconds. Type K thermocouple wire. image 3 and Figure 4 are the measurement results of the interfacial hea...

Embodiment 2

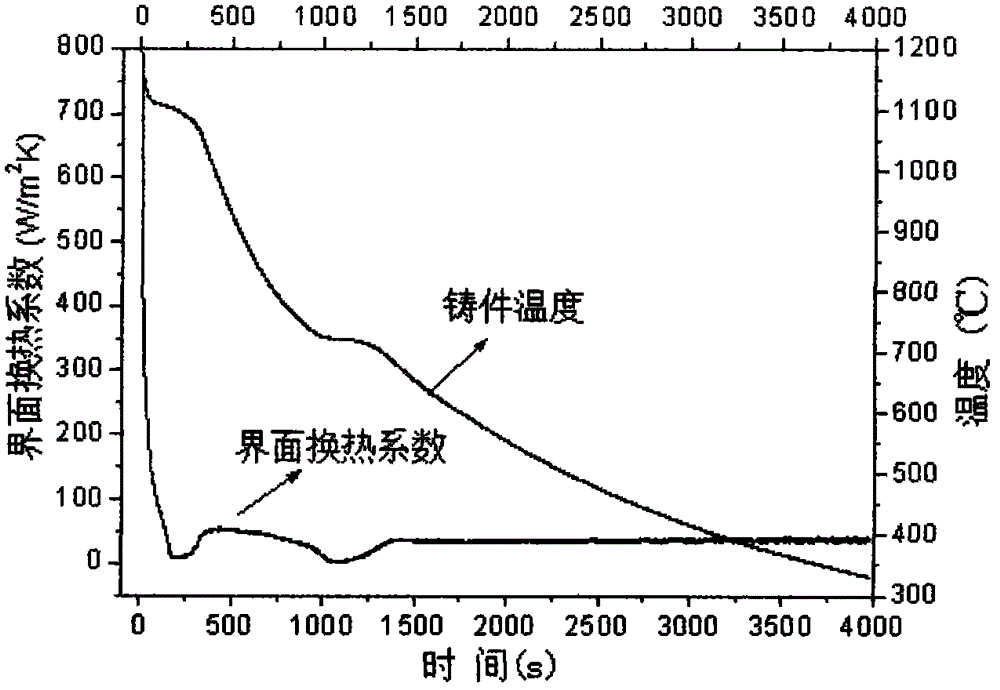

[0043] The present invention is applied to the aluminum alloy metal mold gravity casting experiment. During the experiment, the placement position of the thermocouple is as follows: figure 2 as shown, figure 2 In T1, T2 and T3 are the temperature measurement positions during the experiment, respectively. In the experiment scheme, the pouring temperature is 730°C, and the initial mold temperature is 350°C. In order to accurately measure the heat transfer coefficient of the interface between the casting and the mold, and to avoid the influence of the external environment on the measurement accuracy when the casting is cooled and solidified, the outer surface of the mold is insulated with thermal insulation asbestos during the experiment. K-type thermocouple wire when measuring The time step of collecting data is 0.2 seconds. like Figure 5 Shown are the measured results of the interfacial heat transfer coefficient for a casting with a thickness of 50 mm. from Figure 5 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com