Bioflavonoid impregnated materials

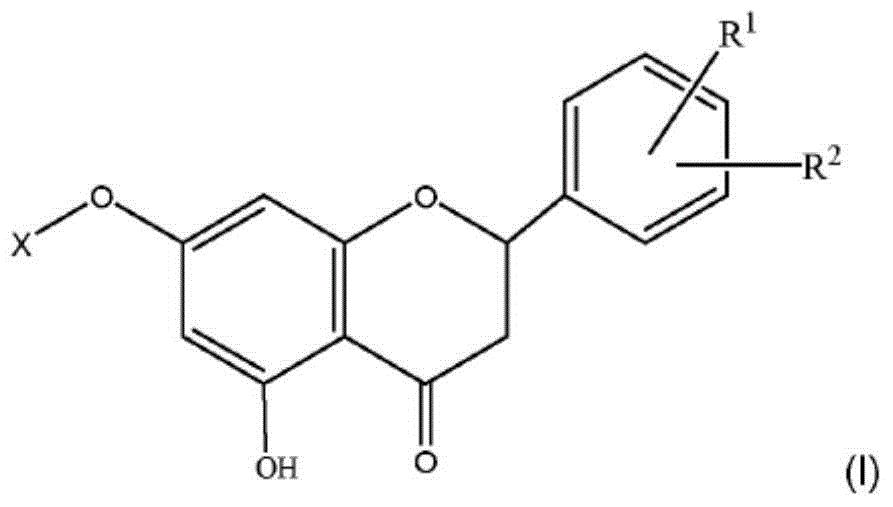

A bioflavonoid, bamboo material technology, applied in the direction of biocide-containing paint, biocide, physical treatment, etc., can solve the problem of impregnating fibers and materials without prompting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: minimum inhibitory concentration (MIC) and minimum bactericidal concentration (MBC)

[0067] program

[0068] Pure cultures of single microorganisms are grown in appropriate broths. Cultures were normalized to have a concentration very close to one million cells / ml using standard microbiological techniques. The microbial cultures are also standardized, the more reproducible the test results. Dilute the antimicrobial reagent multiple times (1:1) with sterile diluent. Following dilution of the antimicrobial agent, a volume of standardized inoculum corresponding to the volume of the diluted antimicrobial agent was added to each dilution vessel to achieve a microbial concentration of approximately 500,000 cells / ml. The inoculated serial dilutions of the antimicrobial agent are incubated at an appropriate temperature for a predetermined time (typically 18 hours) for the organism under test. Following incubation, the serially diluted vessels are observed f...

Embodiment 2

[0080] Example 2: Time kill test

[0081] program

[0082] All timed kill tests were performed using standard viable count procedures. Reference NB X34689. The following neutralizing solutions were used in all kill tests.

[0083]

[0084]

[0085] Fundamental

[0086] The timed kill test evaluates the amount of time required to kill a predetermined population of microorganisms. A wide variety of microorganisms are killed by Citrox BC actives. An important first step in characterizing such actives for antimicrobial towels is to identify the kill requirements. Efficacy claims are based on the number of bacteria killed within a predetermined time frame. The most stringent requirements are those established for food contact, where the active must achieve a 5-log reduction of the challenge organism within 30 seconds.

[0087] Discussion of results

[0088] Example 2(a): Timed kill test: 10 minutes contact time

Embodiment 3

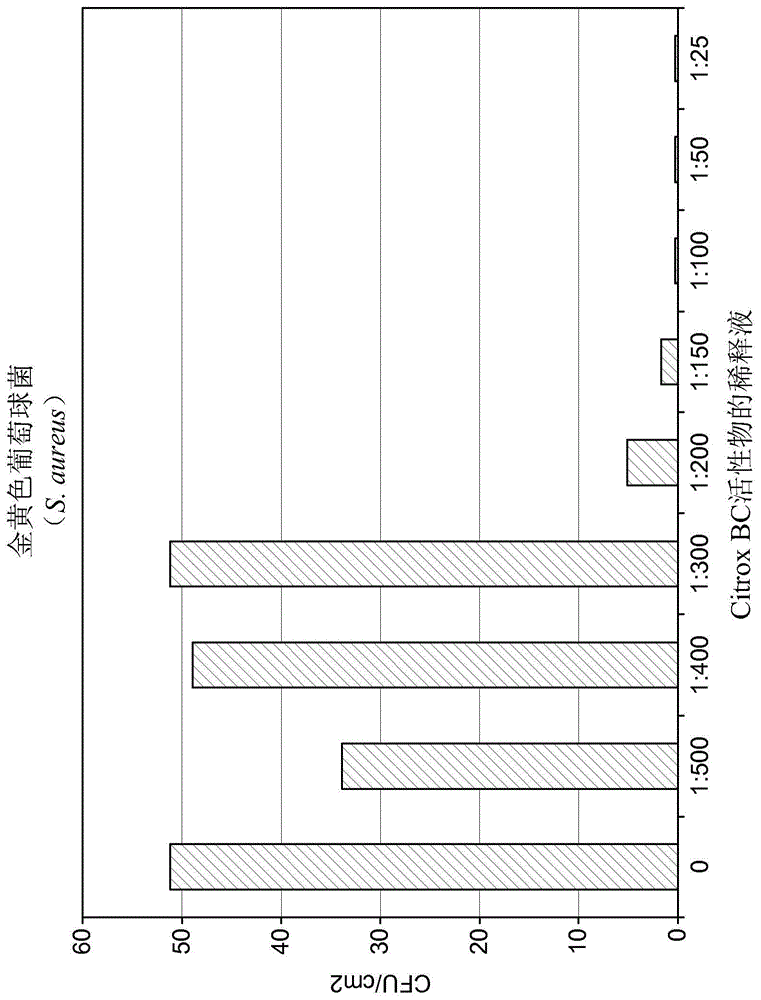

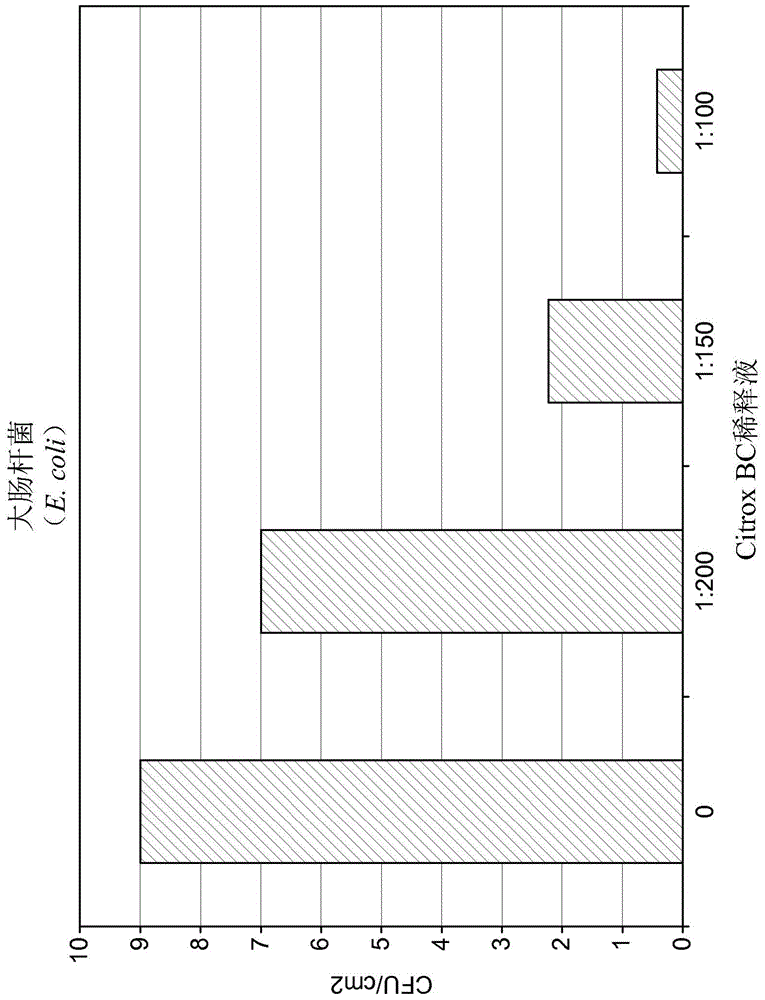

[0101] Example 3: Surface testing using paper towels impregnated with Citrox BC active

[0102] 1) Procedure: Add Citrox BC to paper towels

[0103] ("Bounty" is a registered trademark of Procter & Gamble) brand paper towels were used to make dry antimicrobial towels. The tissue is a conventional commercially available tissue product. Dilute Citrox BC Active Concentrate to desired concentration. Submerge a paper towel completely in the diluted active and wring it out by hand. Let the paper towels dry overnight.

[0104] 2) Procedure: Weight of Citrox BC active dry on brand paper towels

[0105] Will Brand paper towels were dried in an oven at 54°C to constant weight. exist Various dilutions of Citrox BC active were dried on paper towels, as described above. The paper towels were dried overnight at room temperature. The treated tissue was then dried to constant weight at 54°C. The difference in weight between the untreated tissue and the treated tissue is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com