Radiation shielding composite material including radiation absorbing material and method for preparing the same

A radiation-absorbing and radiation-shielding technology, applied in the field of radiation-shielding composite materials, can solve problems such as increased costs and unsuitable shielding components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation method of radiation absorbing material

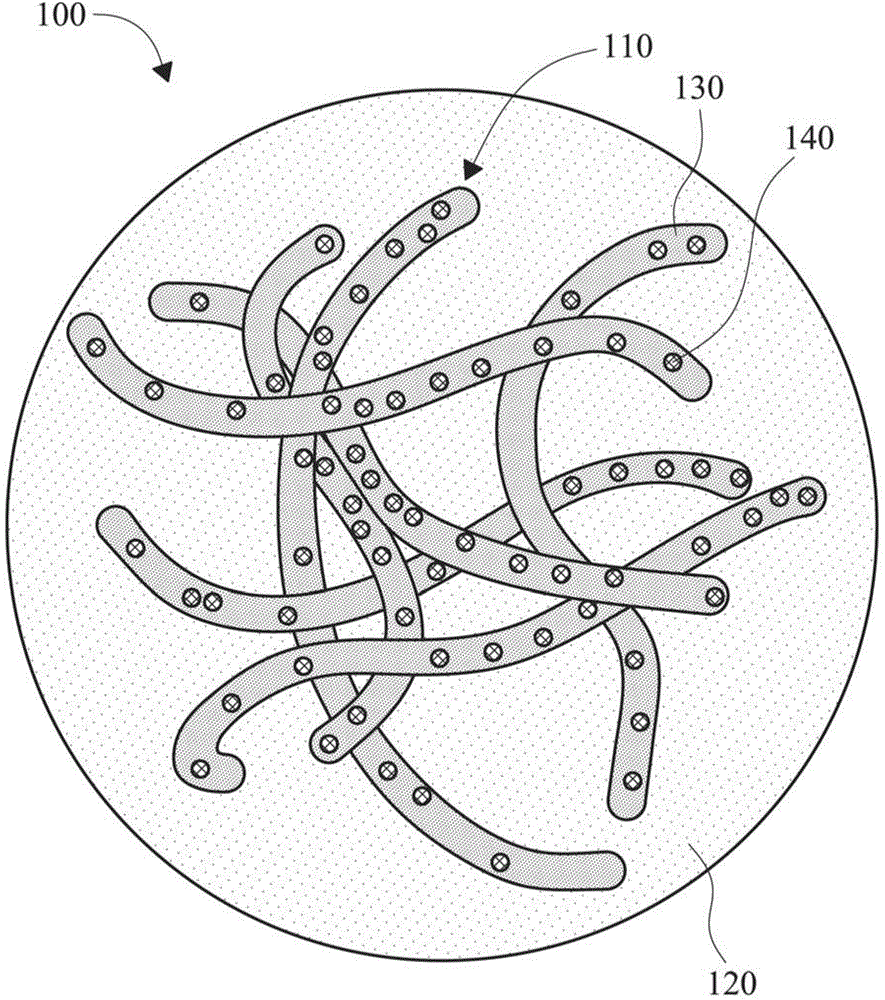

[0041] Figure 5 For the preparation of exemplary embodiments figure 1 A flowchart of a method of radiation absorbing material 110 is shown. In this embodiment, the foreign element 140 is boron. In addition, the carrier 130 of this embodiment is carbon nanotubes.

[0042] When the heterogeneous element 140 is boron, at least one of the following methods can be used to form boron: solid boron precursor, liquid boron precursor, and gaseous boron precursor. Examples of solid boron precursors include boron oxide (B 2 o 3 ), boron carbide (B 4 C), boron nitride (BN), boric acid (H 3 BO 3 ), or any other boron-containing compound. Examples of liquid boron precursors include aqueous boric acid (H 3 BO 3(aq) ), triethyl borate (C 6 h 15 BO 3 ), or the like. Examples of gaseous boron precursors include triethylborane ((C 2 h 5 ) 3 B), boron trichloride (BCl 3 ), diborane (B 2 h 6 ),etc.

[0043] When the ...

Embodiment 1

[0065] Embodiment 1 (preparation of boron-doped carbon nanotubes)

[0066] For sample preparation without pretreatment, first mix boron oxide (B 2 o 3 ) powder and pristine multi-walled carbon nanotubes (MWCNTs) to prepare reactants. The molar ratio of boron to carbon in the reactants may be between 1 and 10. If the molar ratio of boron to carbon is less than 1, boron cannot be effectively doped into MWCNT. If the molar ratio of boron to carbon is greater than 10, most boron is wasted due to insufficient MWCNTs.

[0067] For sample preparation with pretreatment process, first dissolve boron oxide into deionized water at 80°C for pretreatment process. Then pristine MWCNTs were slowly added into deionized water to form a slurry solution. The molar ratio of boron to carbon in the slurry solution can be between 1 and 10. The solution was continuously and uniformly stirred with a magnet, and the rotation speed of the magnet was 450 rpm. The solution containing pristine MWCNT...

Embodiment 2

[0078] Embodiment 2 (preparation of boron-doped nanomaterials)

[0079] The preparation method of this example is similar to Example 1, the difference is that the MWCNT carrier is replaced by various other carriers. Table 2 summarizes samples 30 to 35 prepared using different nanomaterials as supports.

[0080] Table 2

[0081]

[0082] Samples 30, 33, 34, and 35 have very high boron content (greater than 30 at%) and are suitable for neutron absorption and shielding applications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com