Method for preventing gray mold in lily flower cutting facility production in winter and heating air blowing equipment

A technology of gray mold and equipment, applied in the field of planting, can solve the problems of lily production loss, gray mold occurrence, poor ventilation conditions, etc., achieve low installation and use costs, improve the quality of cut flowers, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

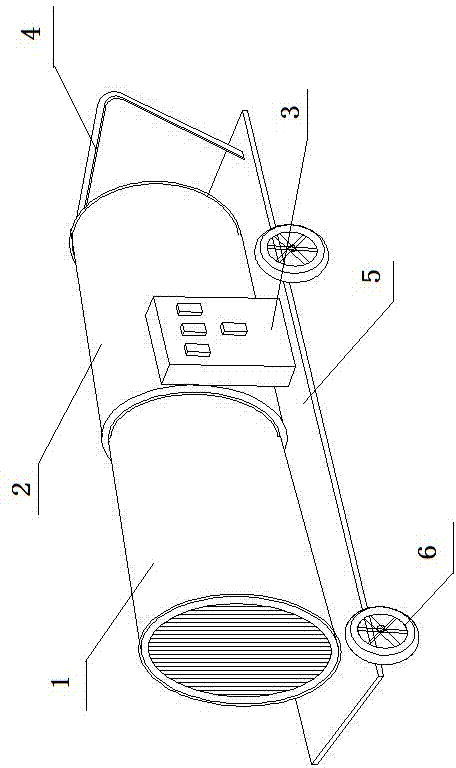

Image

Examples

Embodiment 1

[0019] Embodiment 1, a method for preventing botrytis cinerea in the production of lily cut flower facilities in winter, installs heating and blowing equipment in the lily cut flower cultivation facility, and circulates the heated air through the heating and blowing equipment; the installation position of the heating and blowing equipment is installed according to the wind direction In the downwind position, there is a facility air outlet in the cultivation facility on the other side where the heating and blowing equipment is installed; the outlet air temperature of the heating and blowing equipment is 20°C; the operating cycle of the heating and blowing equipment is 3 times / week, and the running time is 40min / time; the distance between the air outlet of the heating and blowing equipment and the lily plant is 1m; when the relative humidity in the cultivation facility reaches 60%, stop the operation of the heating and blowing equipment.

Embodiment 2

[0020] Embodiment 2, a method for preventing gray mold in the production of lily cut flower facilities in winter, installs heating and blowing equipment in the lily cut flower cultivation facility, and circulates the heated air through the heating and blowing equipment; the installation position of the heating and blowing equipment is installed according to the wind direction In the downwind position, there is a facility air outlet in the cultivation facility on the other side where the heating and blowing equipment is installed; the outlet air temperature of the heating and blowing equipment is 35°C; the operating cycle of the heating and blowing equipment is 5 times / week, and the running time is 60min / time; the distance between the air outlet of the heating and blowing equipment and the lily plant is 2m; when the relative humidity in the cultivation facility reaches 70%, stop the operation of the heating and blowing equipment.

Embodiment 3

[0021] Embodiment 3, a method for preventing gray mold in the production of lily cut flower facilities in winter, install heating and blowing equipment in the lily cut flower cultivation facility, and circulate the heated air through the heating and blowing equipment; the installation position of the heating and blowing equipment is installed according to the wind direction In the downwind position, there is a facility air outlet in the cultivation facility on the other side where the heating and blowing equipment is installed; the outlet temperature of the heating and blowing equipment is 25°C; the operating cycle of the heating and blowing equipment is 4 times / week, and the running time is 50min / time; the distance between the air outlet of the heating and blowing equipment and the lily plant is 1.5m; when the relative humidity in the cultivation facility reaches 65%, stop the operation of the heating and blowing equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com