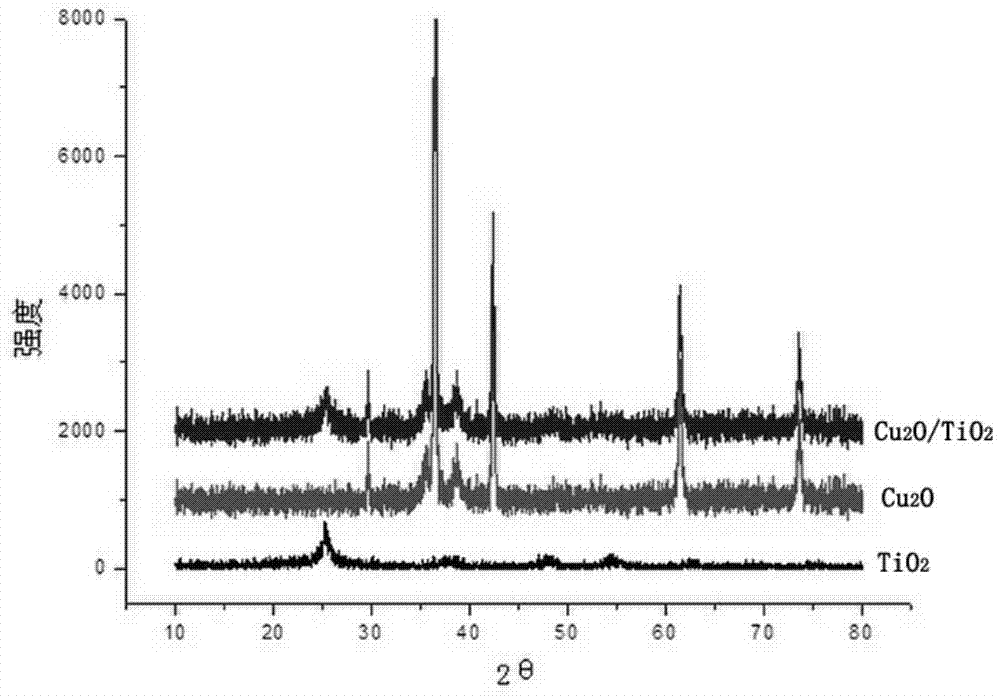

Preparation method for Cu2O/TiO2 composite photo-thermal catalyst

A technology of catalyst and composite light, which is applied in the field of preparation of Cu2O/TiO2 composite photothermal catalyst, can solve problems such as weak penetration of excitation light, difficult separation at the nanometer level, and restrictions on practical application, so as to shorten the sol time and simplify the preparation process , The effect of delaying the hydrolysis-polycondensation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] (2) Nano-TiO 2 Preparation of Catalyst Powder

[0025] Preparation of reaction material raw materials: butyl titanate, absolute ethanol, butyl titanate hydrolysis buffer, distilled water;

[0026] At a temperature of 15°C-35°C, put butyl titanate and absolute ethanol in a pear-shaped separatory funnel, and mix thoroughly to obtain the butyl titanate component, which is denoted as X component; distilled water and hydrolysis buffer Put it in a pear-shaped separating funnel and mix evenly to obtain the distilled water component, which is recorded as Z component; take 20ml-50ml butyl titanate hydrolysis buffer solution into a beaker, and place the beaker under a mechanical stirrer for stirring. The butyl titanate hydrolysis buffer system is obtained, which is recorded as the Y component; the X component and the Z component are added dropwise to the Y component to obtain the butyl titanate hydrolysis system, and the hydrolysis-polycondensation reaction of the butyl titanate...

Embodiment 1

[0033] Example 1Cu 2 Cu with 20% O loading 2 O / TiO 2 Preparation of Composite Photothermal Catalyst

[0034] Process 1: Nano TiO 2 Preparation of Catalyst Powder

[0035] At a temperature of 35°C, put 10ml of butyl titanate and 10ml of absolute ethanol in a pear-shaped separatory funnel and mix thoroughly to obtain the butyl titanate component, which is denoted as X component; 2.1ml of distilled water and 5ml of hydrolyzed Put the buffer solution in a pear-shaped separating funnel and mix thoroughly to obtain the Z component; take 20ml of the hydrolysis buffer solution and put it in a beaker, and place the beaker under a mechanical stirrer for stirring to obtain the hydrolysis buffer solution system, denoted as Y components. Put the Y component under the mechanical stirrer, start the stirring, and add the X component and Z component to the Y component dropwise at the same time. Strictly control the dropping speed of X and Z components during dropping. The dropping speed ...

Embodiment 2

[0038] Example 2Cu 2 Cu with 40% O loading 2 O / TiO 2 Preparation of Composite Photothermal Catalyst

[0039] Process 1: same as embodiment 1 process 1

[0040] Process 2: Cu 2 Cu with 40% O loading 2 O / TiO 2 Preparation of Composite Photothermal Catalyst

[0041] Prepare 1L of CuSO with a concentration of 0.5mol / L 4 solution, take 100mL and add it to a 250mL round bottom flask, and accurately weigh 1g of prepared nano-TiO 2 Put the catalyst powder into the round-bottom flask, place the round-bottom flask on the magnetic stirrer, turn on the magnetic stirring for 30 minutes, and ultrasonically disperse for 30 minutes after stirring; then turn on the magnetic stirring again, and add 1mol / L of NaOH solution, adjust the pH value to 10 to obtain suspension A, place the obtained suspension A in a water bath, heat it in a water bath at 90°C for 40min, and then add 10ml of hydrazine hydrate solution with a concentration of 1mol / L dropwise until no After bubbles were generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com