Preparation method of spring-shaped flux cored solder

A brazing material and spring-shaped technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of difficult large-scale popularization and application, low efficiency, and non-continuous production, etc., and achieves wide application range, convenient use, and excellent performance Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

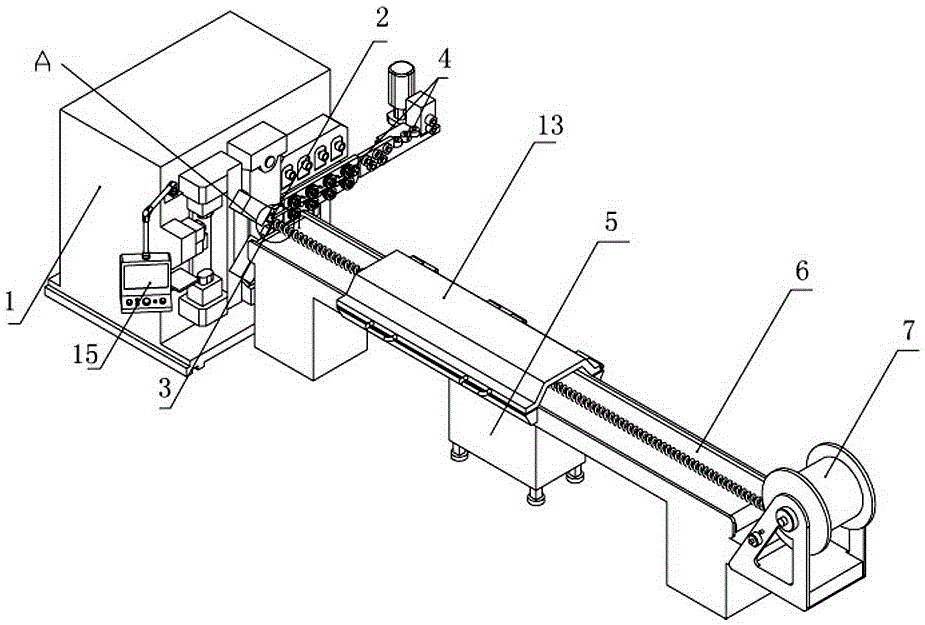

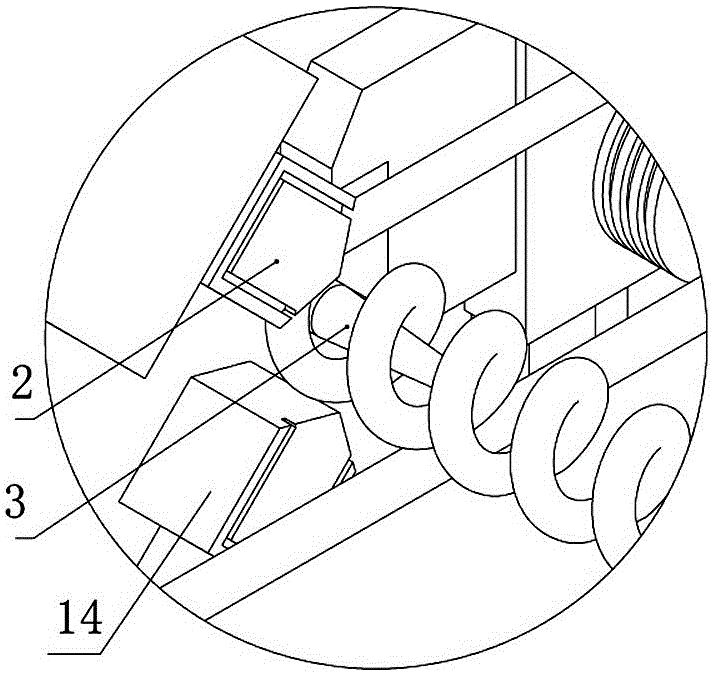

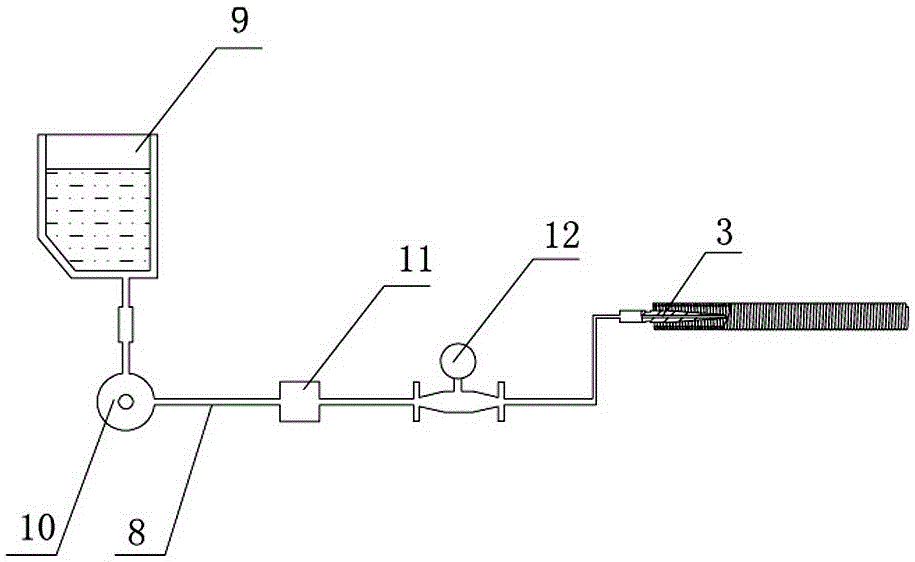

[0032] use figure 1 , 2 The method for producing reed-shaped flux-core solder with the special equipment shown includes the following steps: 1) Combine QJ308 copper flux, diethylene glycol monoethyl ether acetate, and organic binder (the carbon residue after burning is below 10ppm) The flux paste prepared by a certain weight ratio with the toughening agent is placed in the paste flux storage box 9 for use; 2) the wire-shaped BCu58Zn38Mn4 solder with a diameter of 0.8mm is led from the wire feed wheel group 4 to the reed-top knife 2 places; 3) Input the diameters of the solder spring and solder wire on the CNC screen 15 as 2.0mm and 0.7mm respectively (the diameter of the solder spring not explained is the middle diameter of the solder spring by default); 4) Set the core Flux filling flow is 2.8×10 -2 ml / s; 5) Set the temperature of the drying system to 110°C and the wind speed to 0.5m / s; 6) Start the equipment, feed wire, make springs, fill the core with flux, and send it to...

Embodiment 2

[0034] use figure 1 , 2 The method for producing reed-shaped flux-cored solder with the special equipment shown includes the following steps: 1) Flux prepared by a certain weight ratio of QJ103 flux, dimethyl carbonate and organic binder (the carbon residue after combustion is below 10ppm) The paste is placed in the paste flux storage box 9 for use; 2) Lead the wire-like solder with a diameter of 0.4mm from the wire feed wheel group 4 to the reed top knife 2; 3) Input the solder on the numerical control screen 15 The diameters of the spring and the solder wire are 3.0mm and 0.4mm respectively (the diameter of the solder spring without explanation is the middle diameter of the solder spring by default); 4) Set the flux filling flow rate of the core to 16.8×10 -2 ml / s; 5) Set the temperature of the drying system to 100°C and the wind speed to 0.6m / s; 6) Start the equipment, feed wire, make springs, fill the core with flux, and send it to the drying device 15 through the conveyo...

Embodiment 3

[0036] use figure 1 , 2 The method for producing reed-shaped flux-cored solder with the special equipment shown includes the following steps: 1) Prepare the solder with QJ308 flux, acetone, toughening agent and organic adhesive (the carbon residue after burning is below 10ppm) according to a certain weight ratio. The paste is placed in the paste flux storage box 9 for use; 2) Lead the wire-like solder with a diameter of 0.5 mm from the wire feed wheel group 4 to the reed knife 2; 3) Input the brazing on the numerical control screen 15 The diameters of the material spring and the solder wire are 2.5mm and 0.5mm respectively (the diameter of the solder spring without explanation is the middle diameter of the solder spring by default); 4) Set the flow rate of the core flux filling to 8.4×10 -2 ml / s; 5) Set the temperature of the drying system to 120°C and the wind speed to 0.6m / s; 6) Start the equipment, feed wire, make springs, fill the core with flux, and send it to the drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com