High-efficiency coated solder with strong adhesion

A technology with strong adhesion and brazing material, applied in the direction of manufacturing tools, welding/cutting media/materials, welding media, etc., can solve the problems of increased process and operation time, long heating time, and easy-to-corrosion joints, etc., to facilitate transportation and storage , the connector is precise and bright, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the high-efficiency sheath solder with strong adhesion of the present invention is:

[0024] a) Mix silver, copper, zinc, and tin according to the ratio of 34:36:27.5:2.5 and melt them, cast them into Φ50 mm rod-shaped solder alloy ingots, cut off the risers and turn the ingots to remove scale stand-by;

[0025] b) Raise the temperature of the solder extrusion equipment to 460 °C, place the turned ingot in the muffle furnace for preheating, the preheating temperature is 470 °C, put the preheated ingot into the mold of the extrusion equipment Inside, extruded into a Φ1.7 mm brazing wire, and drawn to a Φ0.7 mm brazing wire;

[0026] c) Clean the drawn silver brazing wire and put it into the material tray of the ring-making equipment, wind the brazing wire into a diameter of Φ4.5 mm, the number of turns is 4 turns, and the pitch (two adjacent The axial distance of the corresponding point of the ring on the middle diameter) is a spring-shaped so...

Embodiment 2

[0031] The preparation method of the high-efficiency sheath solder with strong adhesion of the present invention is:

[0032] a) Mix silver, copper, zinc, nickel, and manganese according to the ratio of 49:16:23:4.5:7.5 and melt them, and cast them into Φ50mm rod-shaped solder alloy ingots, cut off the risers and turn the ingots Remove scale for use;

[0033] b) Raise the temperature of the solder extrusion equipment to 460 °C, place the turned ingot in the muffle furnace for preheating, the preheating temperature is 470 °C, put the preheated ingot into the mold of the extrusion equipment Inside, extruded into Φ2.5 mm brazing wire, and drawn to Φ1.0 mm brazing wire;

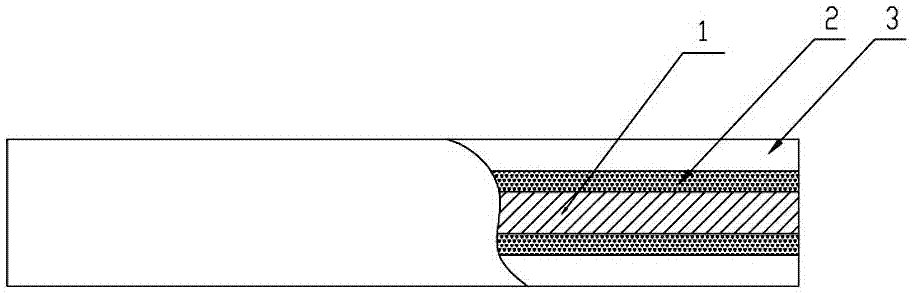

[0034] c) Clean the drawn silver solder wire and put it into the material tray of the ring-making equipment, and wind the solder wire to make a ring-shaped solder core 1 with a middle diameter of Φ8.0 mm;

[0035] d), e) steps are the same as in Example 1.

Embodiment 3

[0037] The preparation method of the high-efficiency sheath solder with strong adhesion of the present invention is:

[0038] a) Mix Cu, Cu-P master alloy and rare earth in proportion and melt them, cast them into Φ50 mm rod-shaped BCu93P7 solder alloy ingots, cut off the risers and turn the ingots to remove scale for later use;

[0039] b) Raise the temperature of the solder extrusion equipment to 450 °C, place the ingot after turning to remove scale in the muffle furnace for preheating, the preheating temperature is 460 °C, put the preheated ingot into the extrusion equipment In the mold barrel, extrude into Φ2.2 mm solder wire, and draw it to Φ2.0 mm silver solder wire;

[0040] c) After the drawn copper-phosphorus-tin solder wire is subjected to frictional texture treatment, it is then cleaned with dilute acid and passivated. After cleaning, it is put into a straightening and cutting machine and cut into 50 mm long solder strips inner core 1;

[0041] d) Weigh phosphoric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com