Novel spunlaced nonwoven material for soft weather-proof building structure and production process for material

A technology of building structure and production process, applied in non-woven fabrics, building elements, textiles and papermaking, etc., can solve the problems of waterproof and anti-seepage performance, the strength in all directions needs to be improved, and achieve increased strength and waterproof performance, high strength , the effect of feeling good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

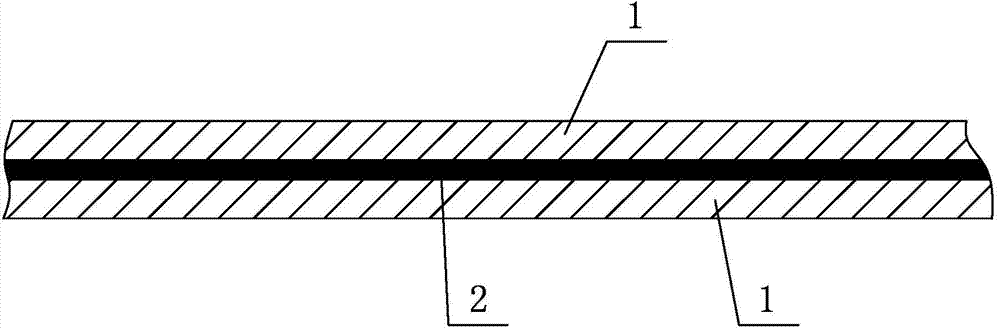

[0024] like figure 1 As shown, the new soft and weather-resistant spunlace nonwoven material of the present invention includes a PE microporous breathable film 2 sandwiched between two layers of polyester spunlace nonwoven materials 1 .

[0025] The production process of the soft and weather-resistant building structure spunlaced nonwoven new material of the present invention specifically includes the following:

[0026] Polyester fiber and PE microporous air-permeable membrane 2 are used as raw materials; firstly, the polyester fiber is fed into the long curtain, horizontal opener, large bin cotton mixing box, fine opener, and then the carding machine, carding machine The second is to carry out layered carding. The raw materials processed by the first carding machine are sequentially fed into the cross-lapper and the drafting machine, and then the raw materials processed by the drafting machine are stacked with the raw materials processed by the second carding machine, an...

Embodiment 2

[0035] like figure 1 As shown, the new soft and weather-resistant spunlace nonwoven material of the present invention includes a PE microporous breathable film 2 sandwiched between two layers of polyester spunlace nonwoven materials 1 .

[0036] The production process of the soft and weather-resistant building structure spunlaced nonwoven new material of the present invention specifically includes the following:

[0037] Polyester fiber and PE microporous air-permeable membrane 2 are used as raw materials; firstly, the polyester fiber is fed into the long curtain, horizontal opener, large bin cotton mixing box, fine opener, and then the carding machine, carding machine The second is to carry out layered carding. The raw materials processed by the first carding machine are sequentially fed into the cross-lapper and the drafting machine, and then the raw materials processed by the drafting machine are stacked with the raw materials processed by the second carding machine, an...

Embodiment 3

[0046] like figure 1 As shown, the new soft and weather-resistant spunlace nonwoven material of the present invention includes a PE microporous breathable film 2 sandwiched between two layers of polyester spunlace nonwoven materials 1 .

[0047]The production process of the soft and weather-resistant building structure spunlaced nonwoven new material of the present invention specifically includes the following:

[0048] Polyester fiber and PE microporous air-permeable membrane 2 are used as raw materials; firstly, the polyester fiber is fed into the long curtain, horizontal opener, large bin cotton mixing box, fine opener, and then the carding machine, carding machine The second is to carry out layered carding. The raw materials processed by the first carding machine are sequentially fed into the cross-lapper and the drafting machine, and then the raw materials processed by the drafting machine are stacked with the raw materials processed by the second carding machine, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com