Automobile air rotary compression energy storage type braking system

A technology of rotary compression and braking system, which is applied to vehicle parts, brakes, transportation and packaging, etc. It can solve the problems of wearing out brake pads, hindering the operation of the transmission, and energy loss, so as to achieve the effect of increasing the braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

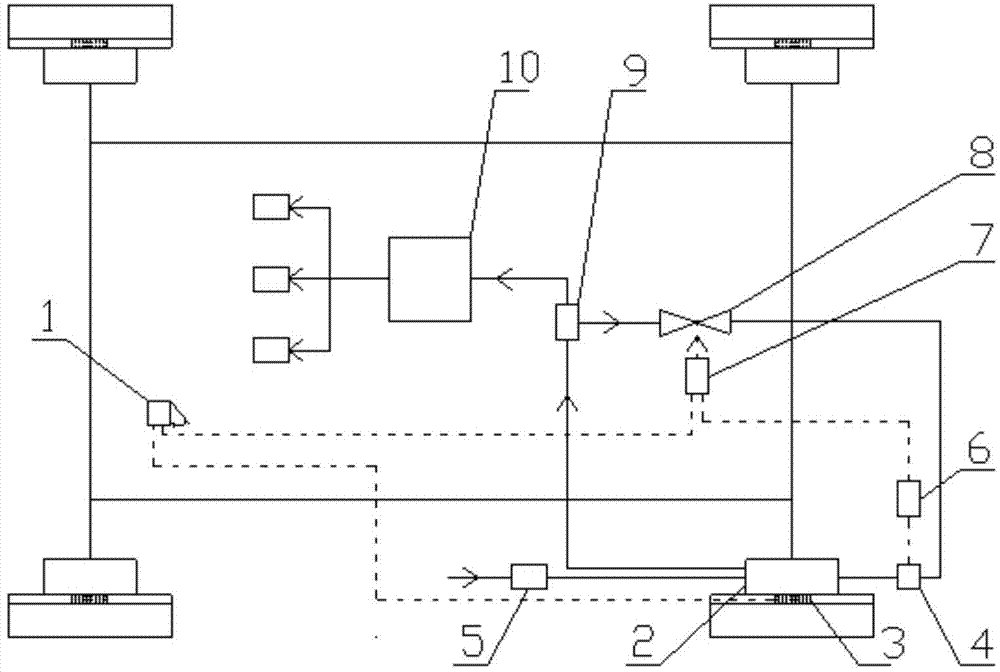

[0027] figure 1 It is a schematic diagram of the system structure of the present invention. As shown in the figure, the system includes: a sliding vane air compression device 2, a pedal and an angular displacement sensor 1, an electromagnetic clutch 3, a pressure feedback transmitter 6, a voltage comparator 7, Solenoid valve 8, low pressure air inlet 5, high pressure air inlet 4, buffer tank 9, gas storage tank 10, and connecting gas pipelines and signal transmission lines.

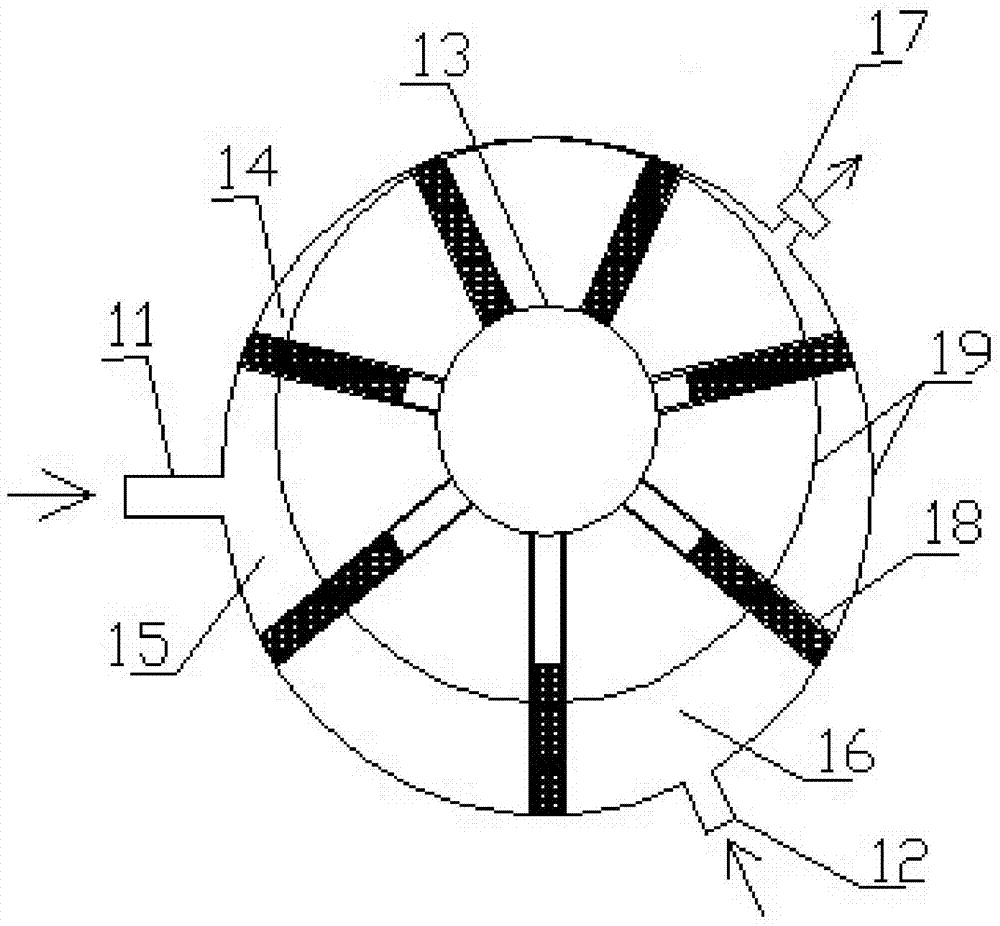

[0028] For the gas pipeline connection circuit, the gas storage tank 1 is connected to the buffer tank 9 through the one-way valve, the buffer tank 9 is connected to the air outlet 17 of the sliding-vane air compression device 2 through the one-way valve, and the sliding-vane air compression device 2 is connected to the electromagnetic Clutch 3, the sliding vane air c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com