Method for preparing granite slurry environment-friendly brick

A technology of environmentally friendly bricks and granite, applied in the field of building materials, can solve the problems of increased production cost pressure, impure color of environmentally friendly bricks, low strength of environmentally friendly bricks, etc., achieve low cost, solve water resources and dust pollution, compressive strength and Excellent frost resistance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

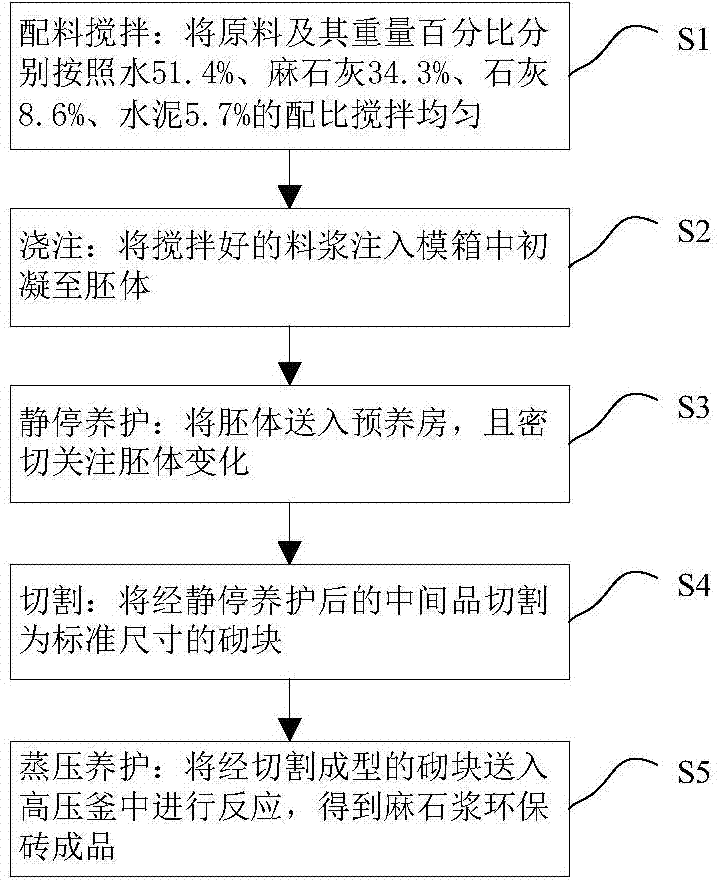

[0017] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

[0018] Please refer to figure 1 , the present invention provides a kind of preparation method of stone pulp environmental protection brick, comprises the following steps:

[0019] S1. Stirring of ingredients: mix the raw materials and their weight percentages according to the ratio of water 51.4%, hemp lime 34.3%, lime 8.6%, and cement 5.7%, respectively;

[0020] S2. Pouring: inject the stirred slurry into the mold box to initially set to the embryo body;

[0021] S3, static maintenance: send the embryo body to the pre-breeding room, and pay close attention to the changes of the embryo body;

[0022] S4. Cutting: cutting the intermediate product after static stop maintenance into blocks of standard size;

[0023] S5. Autoclave curing: send the cut and shaped blocks into an autoclave for reaction to obtain fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com