Thermal insulation material and electronic equipment using same

A heat-insulating material and particle technology, which is applied in heat exchange equipment, mechanical equipment, and pipelines through heat insulation protection, can solve problems such as the inability to set up space, and achieve the effect of preventing heat conduction and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

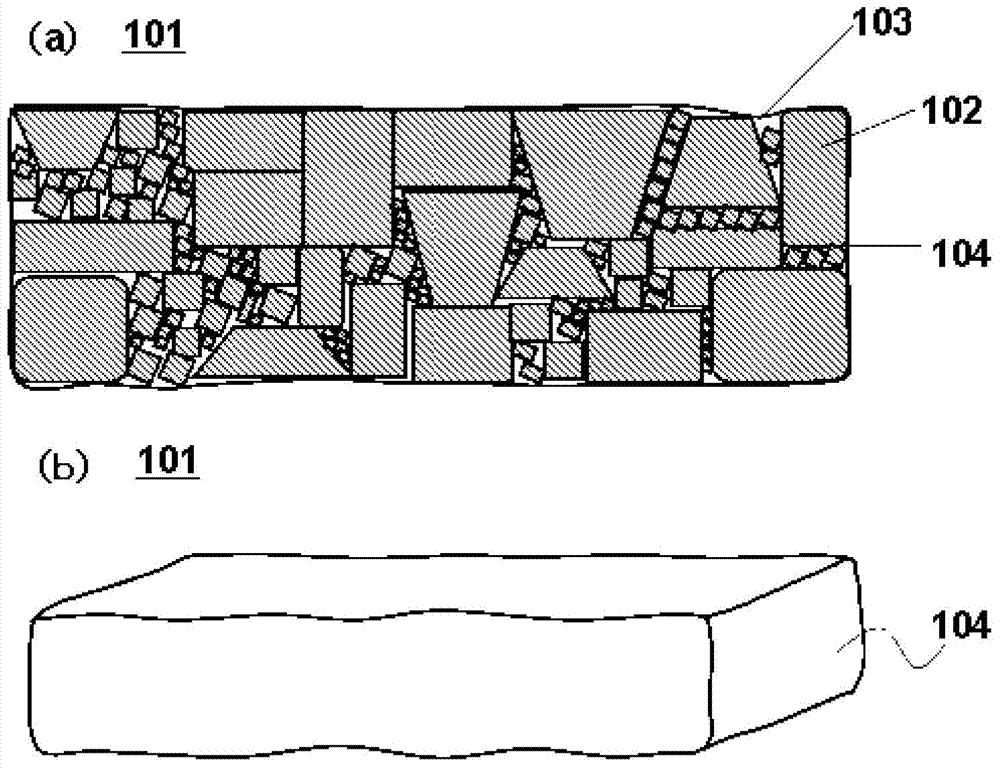

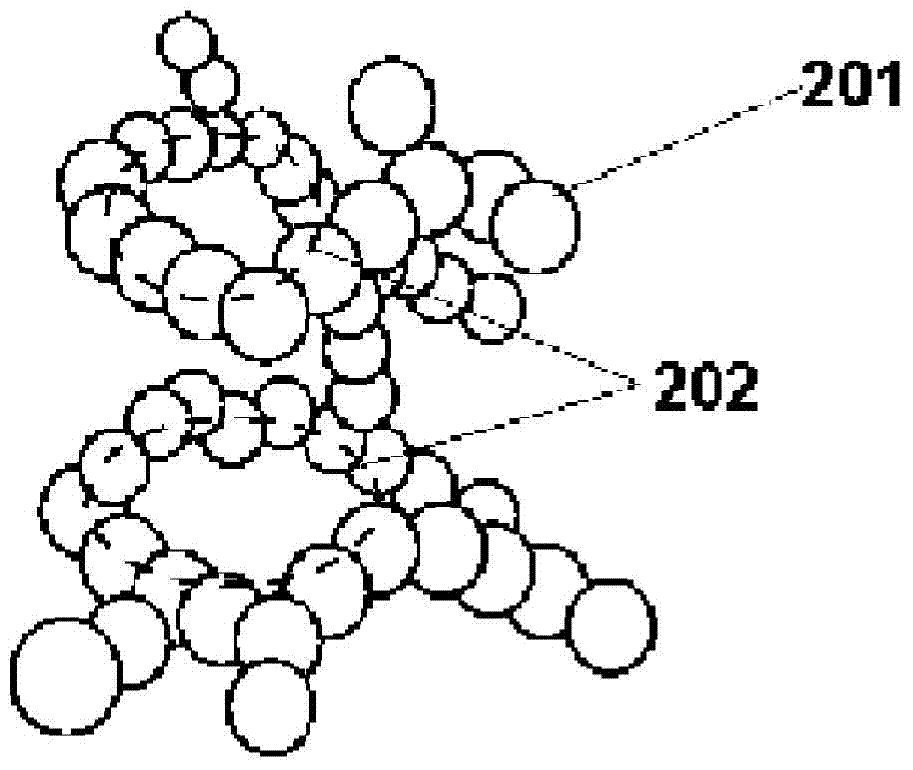

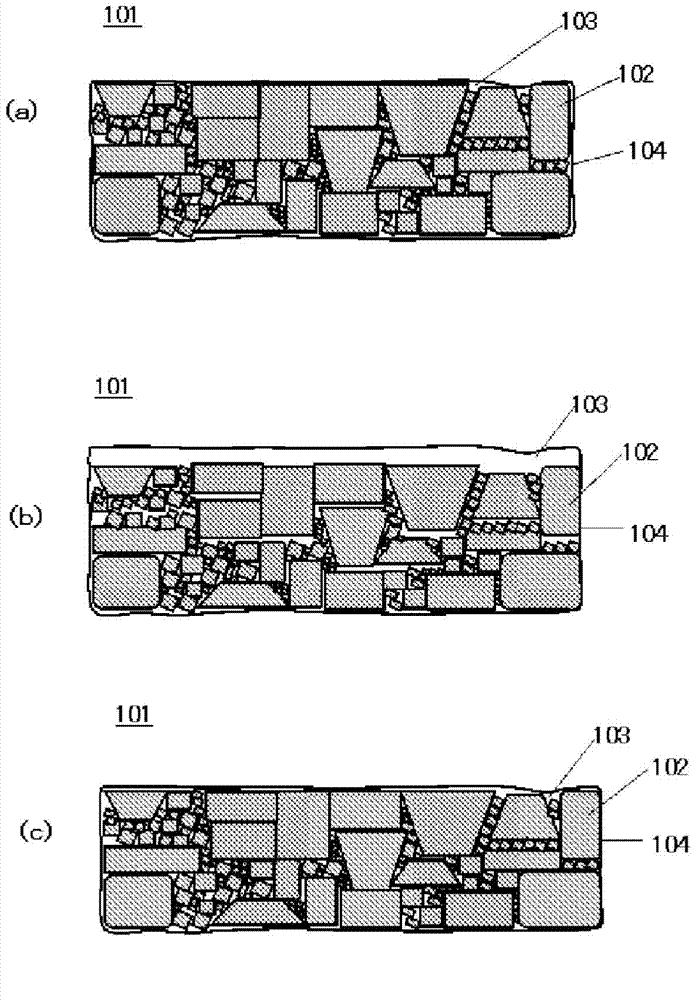

[0056] figure 1 (a) shows the cross-sectional view of the heat insulating material 101 in Embodiment 1. figure 1 (b) shows the perspective view of the heat insulating material 101 in Embodiment 1. also, figure 2 A structural model representing an airgel used in thermal insulation.

[0057] The heat insulating material 101 includes: a block 102 of airgel, an air layer 103, and a resin film 104 covering these parts. As an example, a cuboid heat insulating material is shown.

[0058]

[0059] The size is defined by assuming a cuboid (the smallest cuboid included) covered by contacting each particle. The maximum particle diameter is the length of the longest side among the three sides of the cuboid. The average particle diameter is a diameter obtained by averaging the average values of the three sides of each particle. The following dimensions are defined the same.

[0060] Since the block 102 of airgel needs to be tightly packed in the heat insulating material 101, ...

Embodiment 1

[0082] As Example 1, a heat insulating material 101 ( figure 1 (b)). The block 102 of airgel is enclosed by a resin film 104 . replace Figure 10 The liner 7 of the vending machine shown in (a), (b) is used. That is to say, the heat insulating material 101 is attached to the partition board main body 2 (made of foamed polyurethane), and the heat insulating material 101 is filled with blocks of airgel blocks 102 with an average particle diameter of 10 mm into the blocks made of PE. made of bags.

[0083] If the separator main body 2 with the heat insulating material 101 is as Figure 10 (b) When used in this way, compared with the conventional material, since thermal conductivity is low, it turns out that heat leakage from a gap can be suppressed. The thermal conductivity is 0.02 W / m·K. Furthermore, since it has compression performance, it is also possible to prevent heat leakage.

[0084] In Embodiment 1, regarding the air layer 103 present in the airgel block 102 stuffe...

Embodiment approach 2

[0086] Embodiment 2 is characterized in that the resin film 104 described in Embodiment 1 is provided with a heat-shrinkable function.

[0087] As the heat-shrinkable resin, a heat-shrinkable resin to which the shape memory effect of plastic by electron beam irradiation is applied is used. "Sumiturub" and "Iracustribu" (trademark) manufactured by Sumitomo Electric Industries can be used.

[0088] As the material, polyolefin, polyvinylidene fluoride as a fluoropolymer, thermoplastic elastomer, etc. are selected, but the resin is not limited to these as long as it has shrinkability.

[0089] These resins are characterized in that, when exposed to a temperature of, for example, 100°C, they shrink to about half in a certain direction at the maximum, and the film can increase in thickness direction to reduce the volume of the bag. The thickness and the like of the resin film 104 are the same as those in the first embodiment.

[0090] As mentioned earlier, aerogels are structurall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com