A cement rotary kiln whose lining can be replaced from the outside of the kiln

A cement rotary kiln and lining technology, applied in rotary drum furnace, lining repair, furnace and other directions, can solve the problems of reducing equipment utilization rate, long replacement cycle, etc., to improve utilization rate, increase production, and shorten cold repair time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

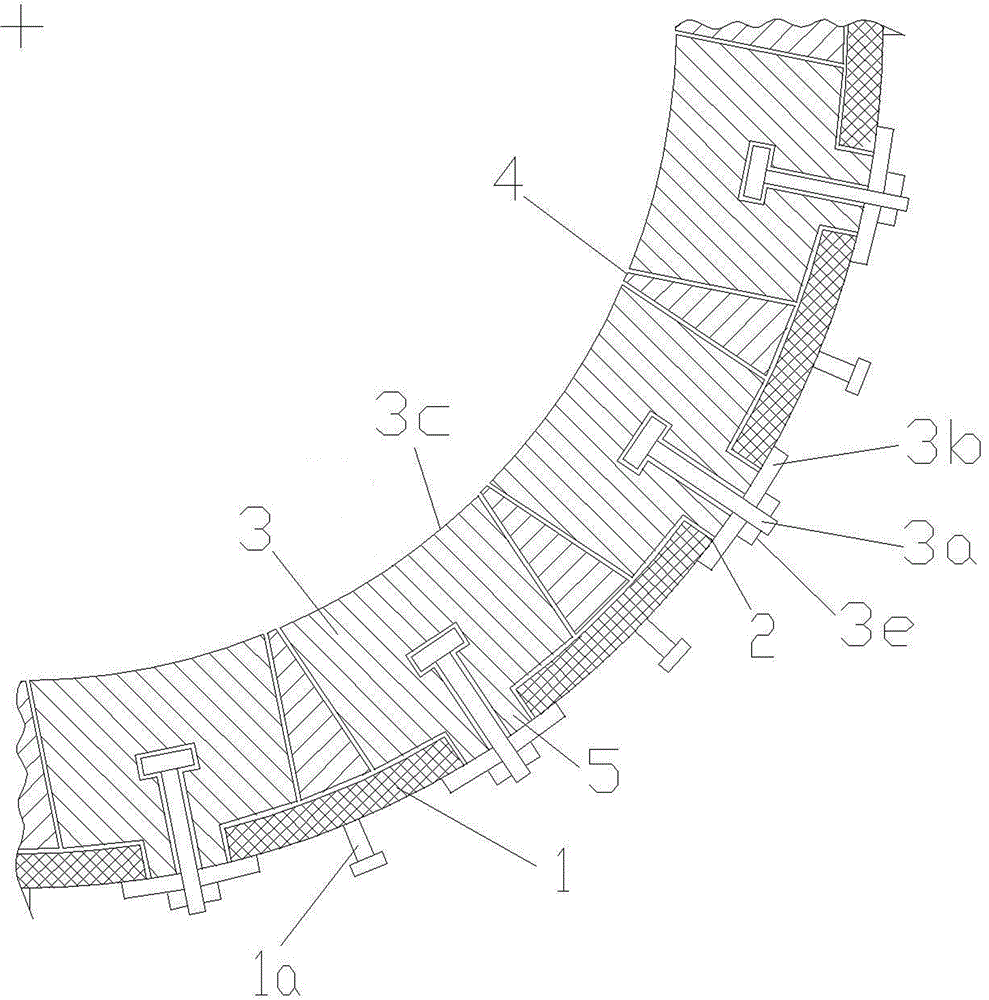

[0018] Such as figure 1 As shown, in a cement rotary kiln whose lining can be replaced from the outside of the kiln, it includes a cement rotary kiln kiln body 1, on which at least one group of long holes 2 is arranged along the circumferential direction, and each long hole There is a certain distance between them, and a reinforcing plate 1a is provided on the outside of the kiln wall of the kiln body 1 .

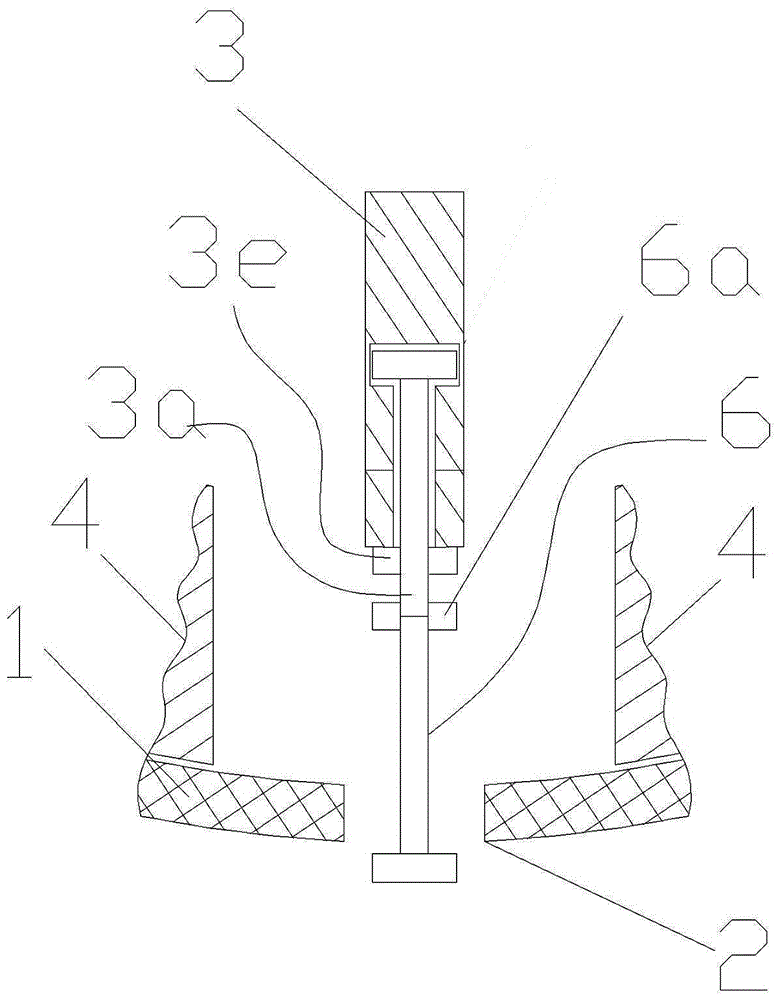

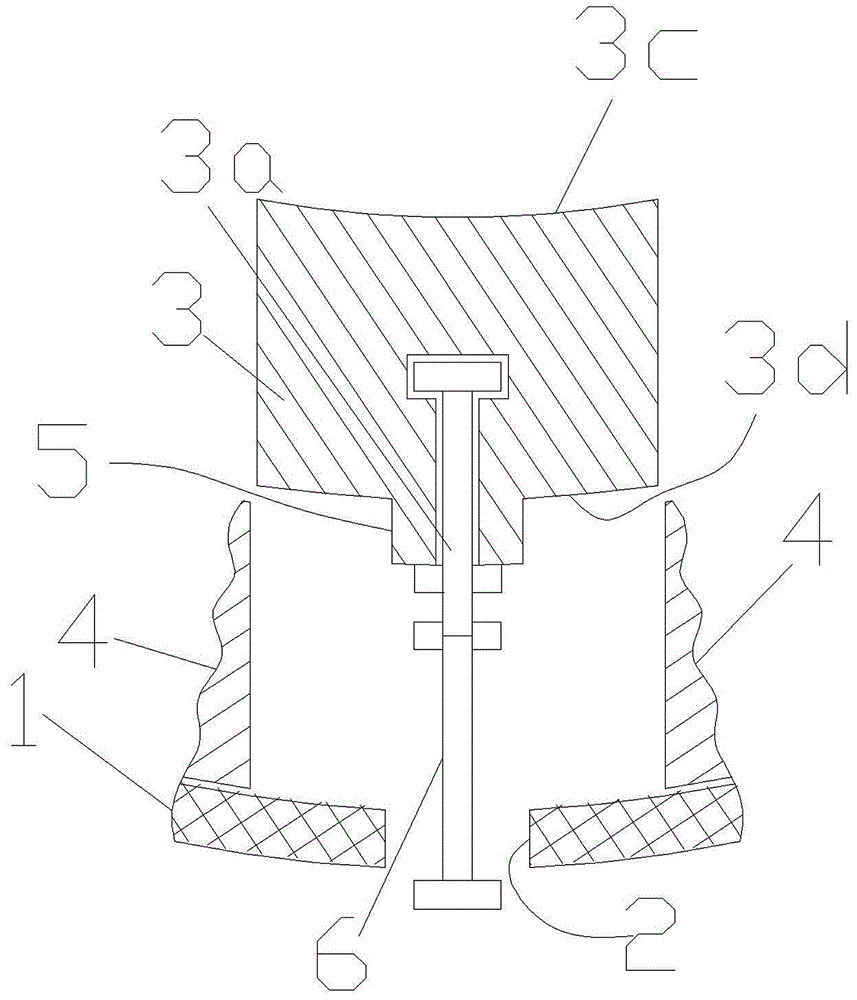

[0019] Such as figure 1 , 2 , 3, set a group of lining bricks 3 that can pass through the long holes, a T-shaped slot is arranged on the lining brick 3, a bolt 3a is arranged in the T-shaped slot, and a bolt 3a is arranged on the bolt 3a. The gusset plate 3b which can cover the elongated hole and whose shape can fit closely with the kiln body is also provided with a fixing nut 3e on the bolt 3a on one side of the gusset plate.

[0020] Such as figure 1 , 3 As shown, an inner arc surface 3c and an outer arc surface 3d are respectively provided on both end surfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com