Machine Vision Based Wafer and Cell Counting Equipment

A technology of machine vision and counting equipment, which is applied in the direction of instrumentation, calculation, image data processing, etc., can solve the problems of large test case, easy to operate improperly, fragile silicon chips or batteries, and fear of pollution, so as to improve the counting accuracy and Effects of system suitability, prevention of contamination and damage to silicon wafers, ease of care and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

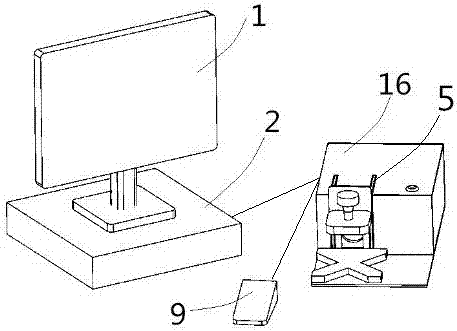

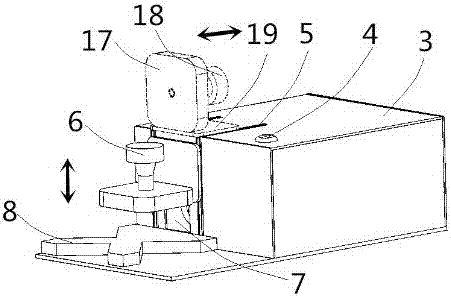

[0018] Such as Figure 1~3 As shown, the silicon chip and cell counting device based on machine vision includes a detection case 16 , a computer screen 1 and a computer case 2 , the computer screen 1 is set on the computer case 2 , and the computer case 2 is connected to the detection case 16 .

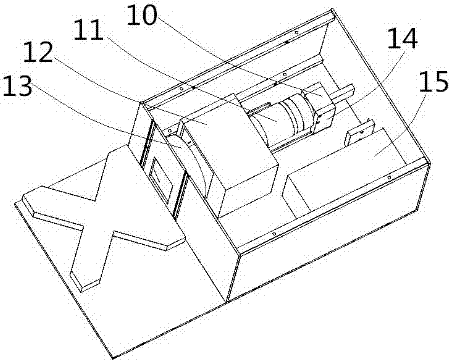

[0019] The detection case 16 includes a box body 3, a detection button 4, a slide rail 5, a pressure plate 6, a detection port 7, a detection table 8, a pedal switch 9, a camera 10, a lens 11, a coaxial light source 12, a ring light source 13, a bracket 14 and a light source controller 15. Detection button 4, slide rail 5, pressure plate 6, detection port 7, detection table 8 and pedal switch 9 are arranged outside the box body 3, camera 10, lens 11, coaxial light source 12, ring light source 13, bracket 14 and light source control The device 15 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com