Pressure-sensitive type display screen touch unit, touch screen and manufacturing method of pressure-sensitive type display screen touch unit

A technology of touch unit and manufacturing method, which is applied in the field of basic sensing unit of touch screen, touch screen and its manufacture, and touch unit of pressure-sensitive display screen, which can solve the problem that the surface is too sensitive to contamination, unable to apply large size, and difficult to perceive static Stress and other problems, to achieve the effect of being sensitive to pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The display screen touch unit and its manufacturing method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

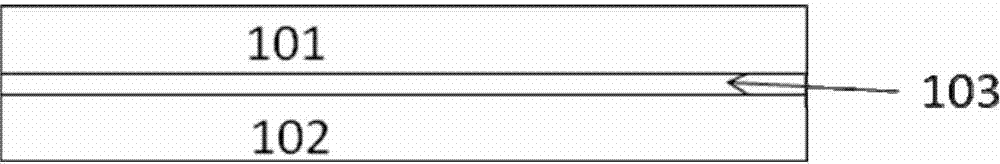

[0025] figure 1 It is a structural schematic diagram of the pressure-sensitive display screen touch unit of the present invention. Such as figure 1 As shown, it describes the most basic unit of a touch pressure sensor, which is mainly composed of an upper electrode (drive electrode) 101 , a lower electrode 102 and an ultra-thin dielectric layer 103 in the middle. in:

[0026] Both the upper electrode 101 and the lower electrode 102 are transparent or translucent conductors, and their materials can be but not limited to indium tin oxide (ITO), aluminum-doped zinc oxide (AZO), fluorine-doped tin oxide (FTO), doped Gallium zinc oxide (GZO), graphene, metal nanowire arrays, etc. Its general film thickness and preparation methods are well known in the industr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com