Vibration sensor and production method thereof

A vibration sensor, polymer technology, applied in sensors, evaluation of respiratory organs, medical science, etc., can solve problems such as poor sensitivity and poor low-frequency response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146] The size of the vibration sensor in this embodiment is 30 mm×12 mm, and the total thickness is about 400 μm. The vibration sensor includes a first electrode layer 21, a first high molecular polymer insulating layer 22, a second high molecular polymer insulating layer 23 and a second electrode layer 24 stacked in sequence, such as image 3 with Figure 4 shown.

[0147] The material used for the first electrode layer 21 and the second electrode layer 24 is aluminum foil with a thickness of 50 μm. The first polymer insulating layer 22 is a composite polymer layer, and the material used is a composite polymer composed of polyethylene terephthalate film (Yongtai Plastic) and polydimethylsiloxane film (Yongtai Plastic). Film with a thickness of 150 μm. The second polymer insulating layer 23 is a single polymer layer, and the material used is polyethylene terephthalate film (Yongtai Plastics), with a thickness of 100 μm. The side of the first high molecular polymer insula...

Embodiment 2

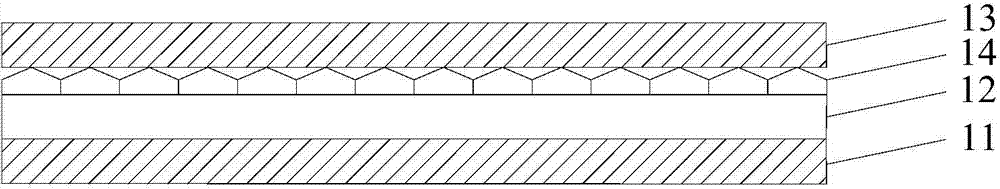

[0152] The size of the vibration sensor of this embodiment is 30 mm×12 mm, and the total thickness is about 400 μm. The vibration sensor includes a first electrode layer 11, a first polymer insulating layer 12, and a second electrode layer 13 that are stacked in sequence, such as figure 1 with figure 2 shown.

[0153] The material used for the first electrode layer 11 and the second electrode layer 13 is copper foil with a thickness of 100 μm. The first polymer insulating layer 12 is a composite polymer layer, and the material used is a composite polymer film (Yongtai Plastics) composed of polyethylene terephthalate film and polypropylene film, with a thickness of 130 μm. On the opposite side of the first high molecular polymer insulating layer 12 and the second electrode layer 13, a diamond-shaped protrusion structure is provided, the height of the protrusion is 50 μm, the length of the long diagonal of the rhombus is 0.1 mm, and the distance between two adjacent rhombus ...

Embodiment 3

[0157] The size of the vibration sensor of this embodiment is 30mm×12mm, and the total thickness is about 1mm. The vibration sensor 3 includes a first electrode layer 31, a first high molecular polymer insulating layer 32, an intervening film layer 33, a second high molecular polymer insulating layer 34 and a second electrode layer 35 stacked in sequence, such as Figure 5 with Image 6 shown.

[0158] The material used for the first electrode layer 31 is copper foil with a thickness of 70 μm, and the material used for the second electrode layer 35 is tungsten with a thickness of 130 μm. The first high molecular polymer insulating layer 32 and the second high molecular polymer insulating layer 34 are both single polymer layers, made of polyethylene terephthalate film (Yongtai Plastics), with a thickness of 100 μm. The intermediate film layer 33 is a composite polymer layer, and the material used is a composite polymer film composed of polyethylene terephthalate film (Yongtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com