Manufacturing method of composite material of doped aligned carbon nanotubes

A carbon nanotube and composite material technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of easy agglomeration and poor orientation of carbon nanotubes, and achieve the effect of good orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

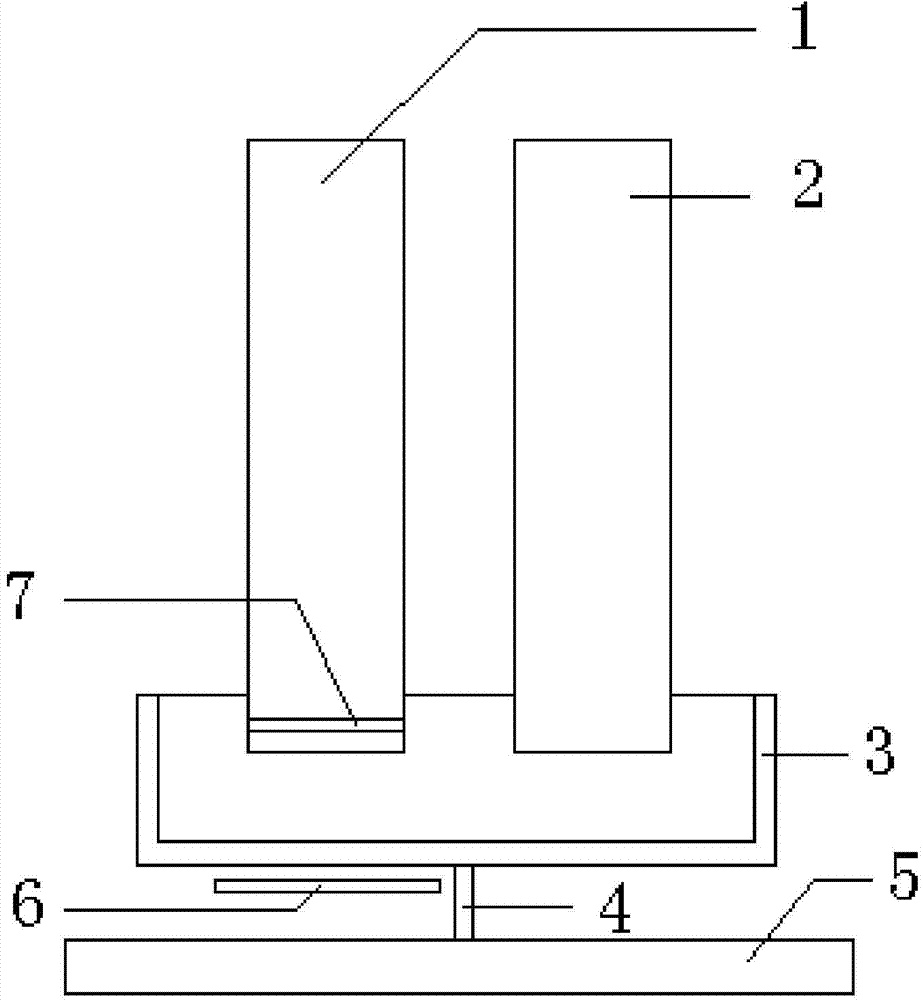

[0017] The present invention will be further described below in conjunction with accompanying drawings and examples.

[0018] The invention provides a method for preparing a composite material doped with aligned carbon nanotubes. The formula is carbon nanotubes and matrix materials, and the specific ratio is determined according to production requirements.

[0019] Its preparation process comprises the following steps:

[0020] (1) The gas-phase dispersed carbon nanotube airflow passes through the high-voltage cathode metal mesh (7) in the carbon nanotube air channel (1) and enters a uniform electric field. Orientation is completed in

[0021] (2) The oriented carbon nanotubes fall into the receiving dish (3) perpendicular to the direction of the electric field;

[0022] (3) The atomized base material falls into the receiving tray (3) from the base material air channel (2) driven by the air flow;

[0023] (4) During the working process, the receiving plate (3) rotates at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com