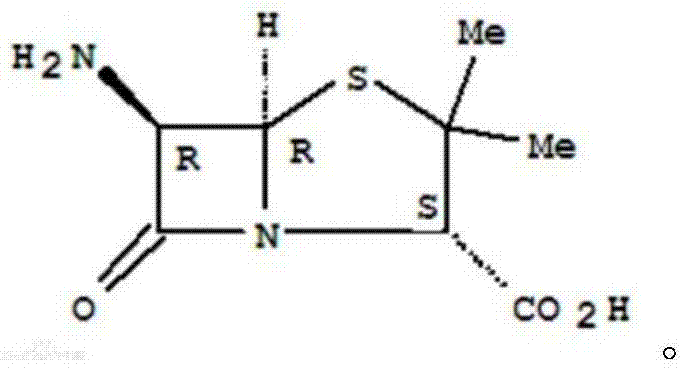

Method for continuously crystallizing 6-amino-penicillanic acid

A technology of crystallization of aminopenicillanic acid, which is applied in the field of medicine, can solve problems such as the inability to realize automatic control, increase the cost of production enterprises, and unstable product quality, and achieve the effect of ensuring uniformity, reducing waste of resources, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The volume of the reaction tank is 100L, the set height of the liquid level in the reaction tank is 60% of the height of the reaction tank, and the bottom end of the stirring paddle is located at 2 / 3 of the set liquid level.

[0035] The volume of the crystallization tank is 100L, and the set height of the liquid level in the crystallization tank is 60% of the height of the crystallization tank.

[0036] There are five sets of filtering devices.

[0037] a. The lysate with a 6-APA content of 22% is continuously fed into the pipeline mixer at a constant flow rate of 20 L / min, and at the same time, butanol is continuously fed into the pipeline mixer at a constant speed of 4 L / min , the two are mixed to obtain a mixed solution;

[0038] b. Control the temperature of the reaction tank at 10°C, turn on the stirring, and continuously pass the mixed solution in the pipeline mixer into the reaction tank at a constant flow rate of 24L / min, and at the same time, add 20% hydrochl...

Embodiment 2

[0044] The volume of the reaction tank is 100L, the height of the liquid level in the setting reaction tank is 80% of the height of the reaction tank, and the bottom end of the stirring paddle is located at 1 / 2 of the setting liquid level.

[0045] The volume of the crystallization tank is 100L, and the set height of the liquid level in the crystallization tank is 80% of the height of the crystallization tank.

[0046] There are three sets of filtering devices.

[0047] a. The lysate with a 6-APA content of 28% is continuously fed into the pipeline mixer at a constant flow rate of 30 L / min, and at the same time, butanol is continuously fed into the pipeline mixer at a constant speed of 6 L / min , the two are mixed to obtain a mixed solution;

[0048] b. The temperature of the reaction tank is controlled at 5°C, the stirring is turned on, and the mixed solution in the pipeline mixer is continuously passed into the reaction tank at a constant flow rate of 36L / min, and 20% aqueou...

Embodiment 3

[0054] The inventor has carried out quality detection to the 6-aminopenicillanic acid that embodiment 1-2 obtains, and the result is shown in table 1, table 2.

[0055] Table 1

[0056] sample

content

simple

total miscellaneous

color grade

Example 1-1

99.5%

0.21%

0.53%

2#

0.3%

Example 1-2

99.4%

0.32%

0.54%

2#

0.3%

Example 1-3

99.3%

0.31%

0.51%

2#

0.2%

Example 1-4

99.5%

0.24%

0.49%

2#

0.2%

Example 1-5

99.2%

0.23%

0.55%

2#

0.3%

[0057] Table 2

[0058] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com