High-resolution grating interferometer based on high-density gratings

A grating interference, high-resolution technology, applied in the field of high-resolution grating interferometers, can solve the problem of low optical subdivision multiples, and achieve the effect of improving optical resolution and high optical subdivision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

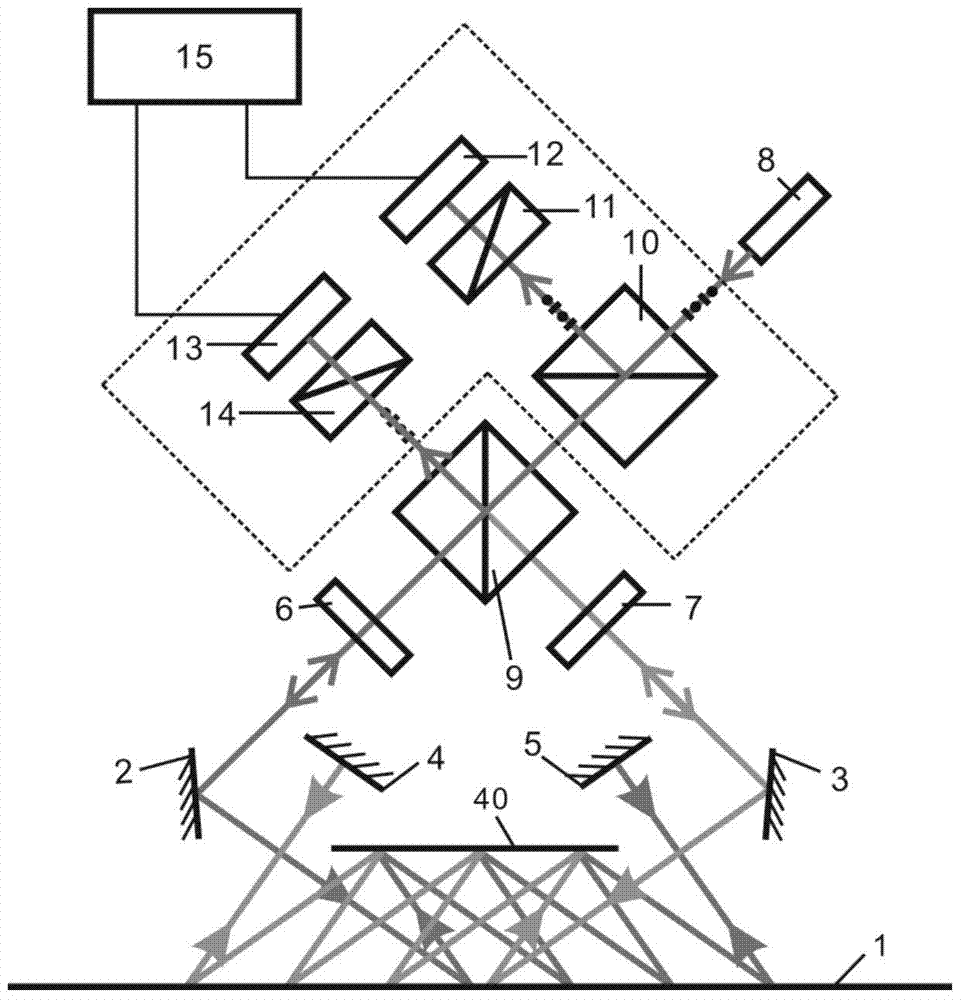

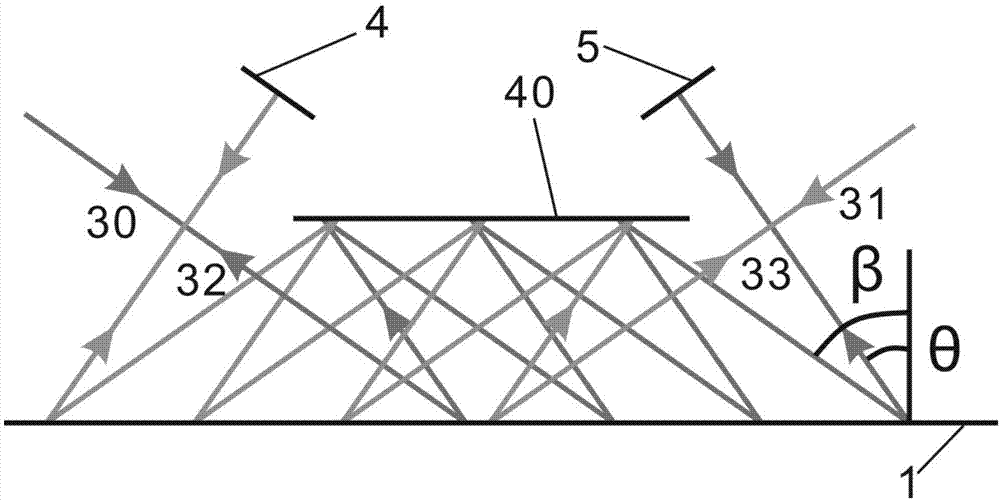

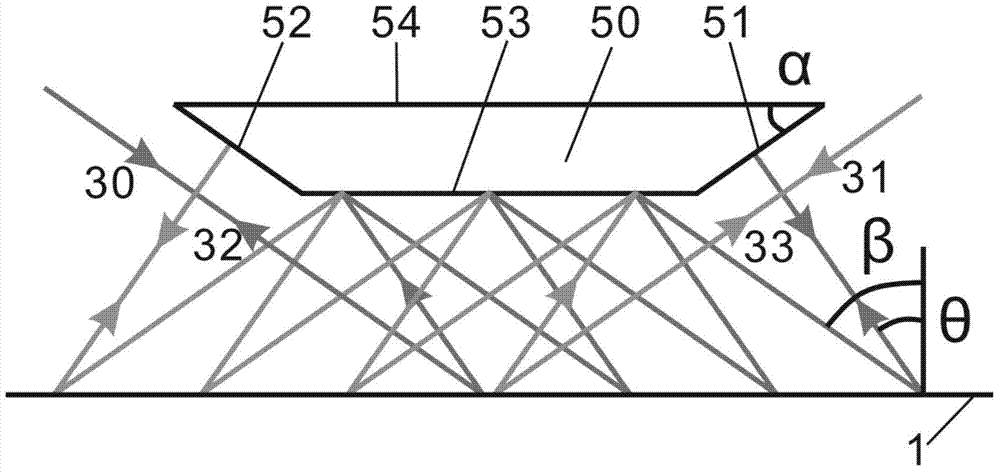

[0023] Such as figure 1 As shown, the laser 8 emits orthogonal dual-frequency linearly polarized light, which is split into two beams by a non-polarizing beam splitter 10, and one beam is formed after passing through the first analyzer 11 placed at 45 degrees to the orthogonal dual-frequency linearly polarized light The interference signal is received by the first photodetector 12 as the reference signal of the dual-frequency heterodyne interferometry; the other beam is divided into the transmitted P light and the reflected S light by the polarizing beam splitter 9, respectively by the first quarter The wave plate 6 and the second quarter wave plate 7 transform it into circularly polarized light, and then enter the scale diffraction grating 1 through the first reflector 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com