Electromechanical impedance method-based portable hardness detection structure and detection method thereof

A technology for detecting structure and electromechanical impedance, which is applied in the direction of testing material hardness, measuring devices, strength characteristics, etc., can solve the problems of large quality and volume, inability to eliminate the error of pit fillet, and inconvenient industrial promotion and use, etc., and achieve simple detection structure , Speed up measurement efficiency and improve measurement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

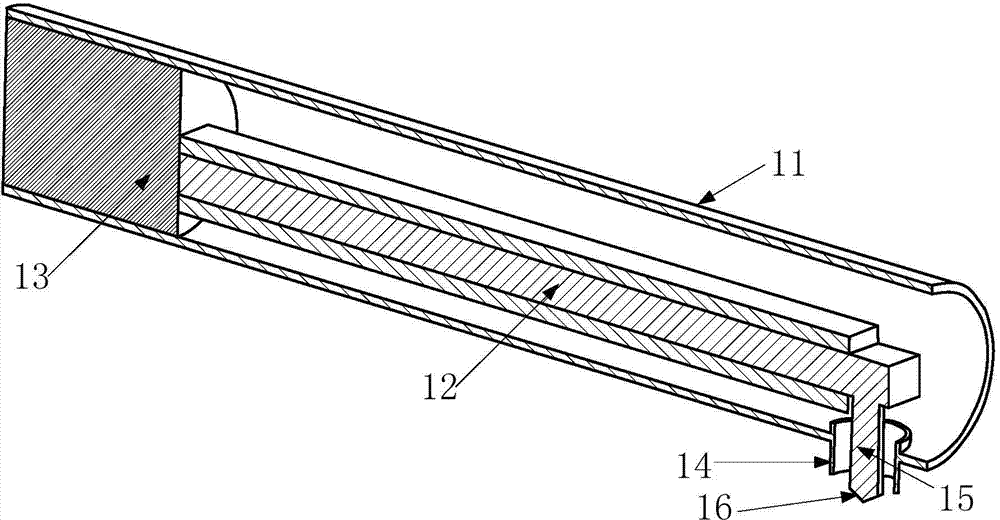

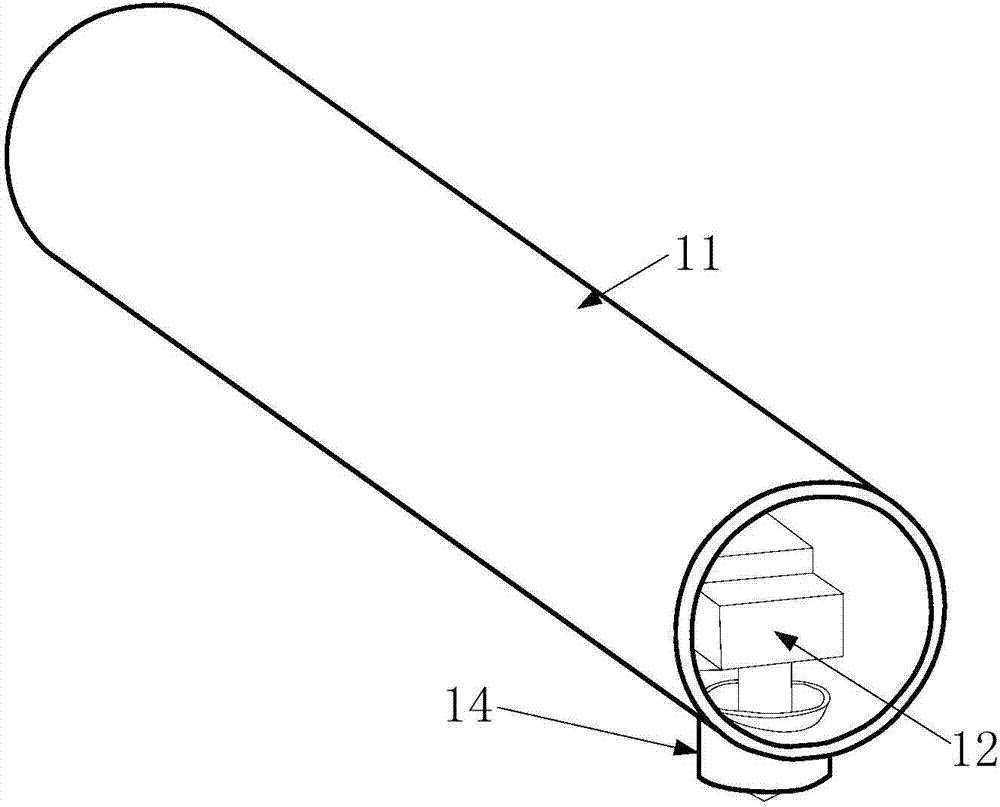

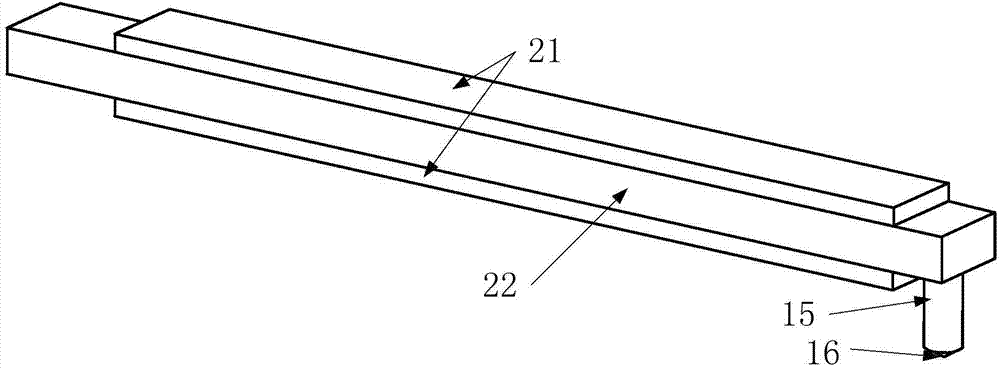

[0035] Such as figure 1 As shown, the portable hardness detection structure based on the electromechanical impedance method of this embodiment includes: a hollow cylinder 11, a piezoelectric twin crystal beam 12, a support block 13, a limit tube 14, a needle point 15 and a hardness tester head 16; wherein, the hollow One end of the tube 11 is a solid support block 13, and the side wall of the other end is provided with a limit tube 14, the axis of the limit tube 14 is perpendicular to the axis of the hollow tube 11; one end of the piezoelectric double crystal beam 12 is fixed by the support block 13 In the hollow cylinder 11, the other end is a free end, and a needle point 15 is provided. The axis of the needle point 15 is perpendicular to the surface of the piezoelectric bicrystalline beam 12, and extends out of the hollow cylinder 11 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com