Corrosive wear test device and using method thereof

A corrosion and wear test, corrosion liquid technology, applied in the field of corrosion and protection, material wear, can solve the problems of electrochemical information collection difficulties, fast rotation speed, liquid flow chaos, etc., to achieve good test repeatability, simple operation, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

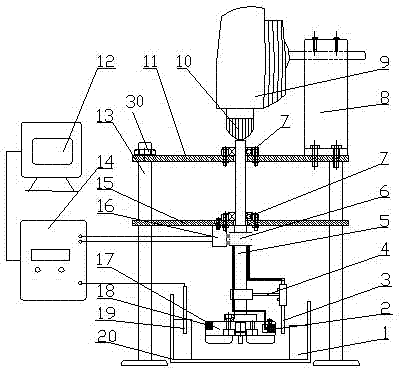

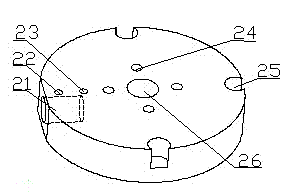

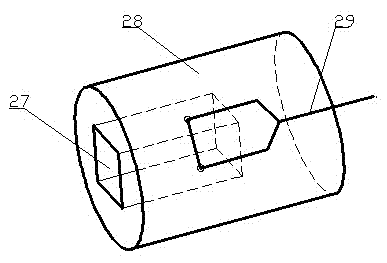

[0031] refer to Figure 1 to Figure 4

[0032] A corrosion and wear test device, comprising a frame, the frame is provided with a vertical DC carbon-free motor 9, the vertical DC carbon-free motor can realize precise control of the number of revolutions of 0 ~ 2000rad / min; when starting, by The low speed slowly increases to the set number of revolutions, which ensures the stability of the overall device. In addition, the motor can also achieve timing and has an overheating protection function.

[0033] The output shaft of the above-mentioned vertical DC carbon-free motor is connected with the transmission shaft 5 vertically arranged on the frame, and the lower end of the transmission shaft is connected with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com