High-performance stokehole liquid iron management analysis system

An analysis system, molten iron technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., to achieve the effects of high efficiency, easy expansion, and high short-term prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] 1. The structure and specific working process of the molten iron management analysis system in front of the furnace:

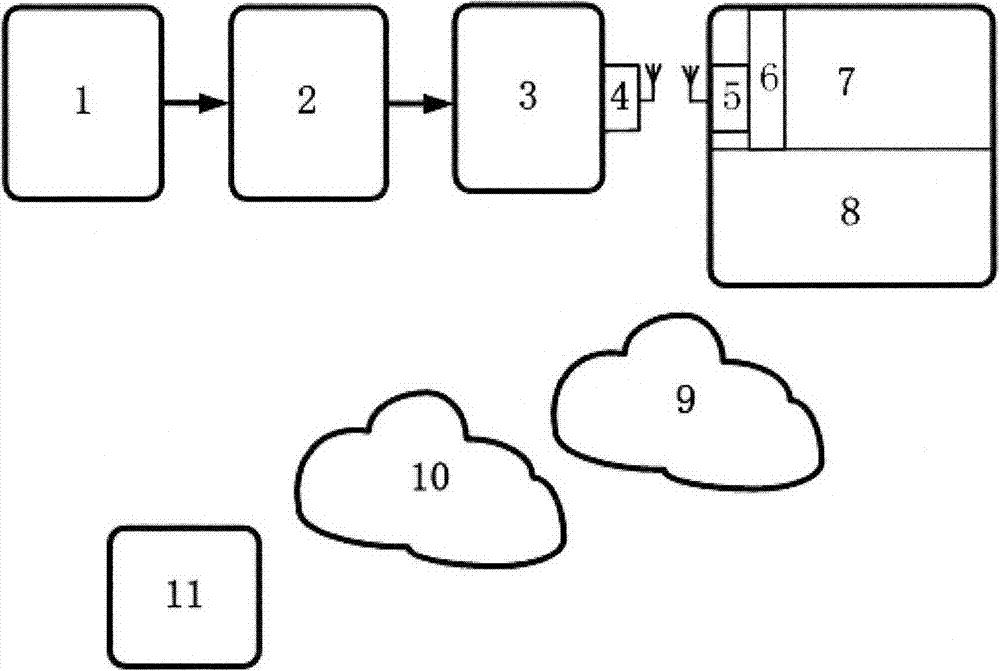

[0019] see figure 1 , a high-performance molten iron management and analysis system in front of the furnace consists of: molten iron furnace 1, thermal analysis sensor 2, signal amplification and conditioning circuit 3, bluetooth sending module 4, bluetooth receiving module 5, data acquisition card 6, virtual instrument 7, computer 8 , Internet network 9, GPRS network 10, mobile phone 11.

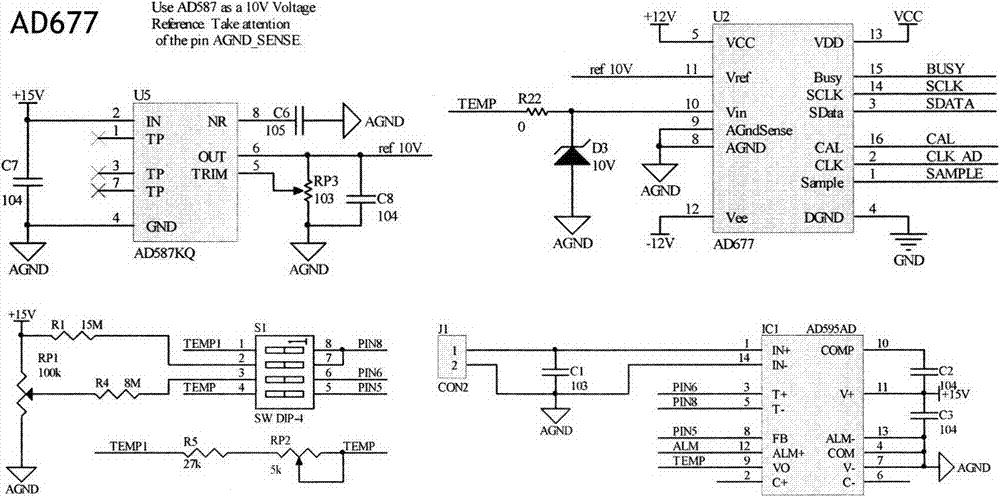

[0020] The thermal analysis sensor 2 is installed on the furnace body of the molten iron furnace 1, and transmits the temperature analog signal to the signal amplification and conditioning circuit 3. After signal conditioning of the analog signal by the signal amplification and conditioning circuit 3 , it is converted into a digital signal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com