Cleaning skin-care substrate and preparation method thereof

A matrix and cleaning technology, applied in the field of cleaning skin care matrix and its preparation, can solve the problems of affecting the stability and skin feel of paste, poor balance of overall efficacy, reducing mildness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The present invention provides a kind of preparation method of cleaning skin care matrix described in above-mentioned technical scheme, comprises the following steps:

[0078] Mixing lauric acid, stearic acid, palmitic acid, myristic acid, the first emulsifier and the second emulsifier to obtain the A-phase material;

[0079] Mixing the first moisturizing agent, the pH regulator, the second moisturizing agent, the first thickener and the chelating agent to obtain the B-phase material;

[0080] mixing the first surfactant, the second surfactant, the third surfactant and the fourth surfactant to obtain the C-phase material;

[0081] mixing phase A material, phase B material, water, phase C material and phase D material, and aging to obtain a clean skin care base;

[0082] The D-phase material is the second thickener.

[0083] The preparation method provided by the invention is simple, controllable and has good repeatability.

[0084] In the present invention, the mixin...

Embodiment 1

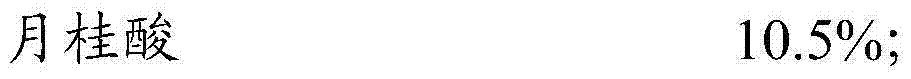

[0100] Phase A material:

[0101]

[0102]

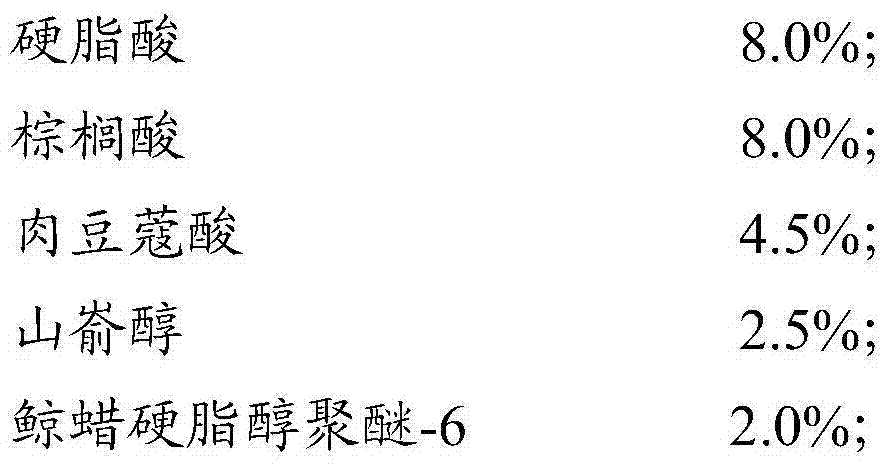

[0103] Phase B material:

[0104]

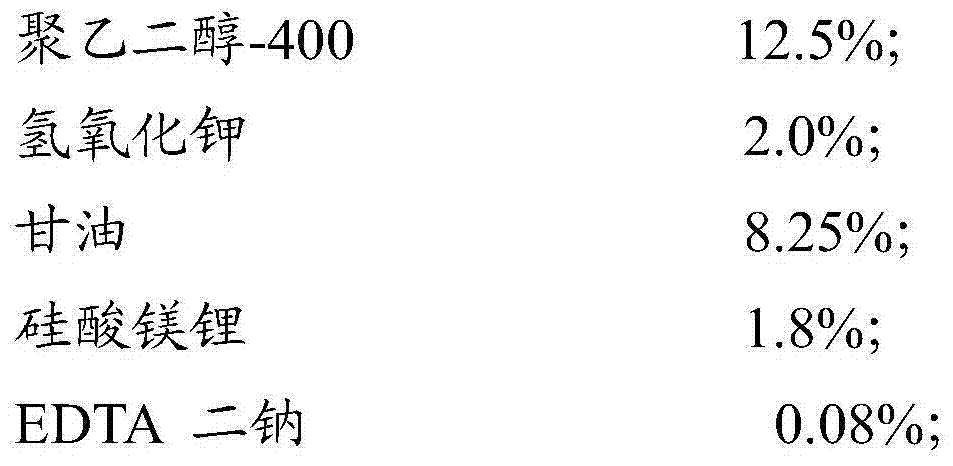

[0105] Phase C material:

[0106]

[0107] Phase D material:

[0108] Acrylic acid (ester) / palmitoleth-25 acrylate copolymer 1.2%;

[0109] The balance is deionized water.

[0110] (1) Mix and stir the components of the A-phase material and heat to 85°C with a stirring speed of 600r / min, and stir and dissolve to obtain the A-phase material, which is set aside;

[0111] (2) Mix and stir the components of phase B material with deionized water and heat to 85°C with a stirring speed of 1000r / min, homogenize for 4min, and keep warm for 30min to obtain the material solution of phase B for later use;

[0112] (3) Slowly filter the material of phase A and add it to the material solution of phase B. After pumping, keep the temperature at 85°C in vacuum and stir for 90 minutes at a stirring speed of 600 r / min to obtain the mixed material A for later use.

[0113] (4) Add the components of t...

Embodiment 2

[0125] Phase A material:

[0126]

[0127] Phase B material:

[0128]

[0129] Phase C material:

[0130]

[0131] Phase D material:

[0132] Acrylic acid (ester) / palmitoleth-25 acrylate copolymer 1.3%;

[0133] The balance is deionized water.

[0134] (1) Mix and stir the components of the A-phase material and heat to 85°C with a stirring speed of 600r / min, and stir and dissolve to obtain the A-phase material, which is set aside;

[0135] (2) Mix and stir the components of phase B material with deionized water and heat to 85°C with a stirring speed of 1000r / min, homogenize for 4min, and keep warm for 30min to obtain the material solution of phase B for later use;

[0136] (3) Slowly filter the material of phase A and add it to the material solution of phase B, then keep it in vacuum at 85° C., stir for 90 min at a stirring speed of 600 r / min, and obtain the mixed material A, which is set aside.

[0137] (4) Add the components of the C-phase material to the mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com