Miniature coal-fired boiler dust collector

A technology for coal-fired boilers and dust removal devices, which is applied in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high construction cost, complex design structure, etc., and achieve the effect of good dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

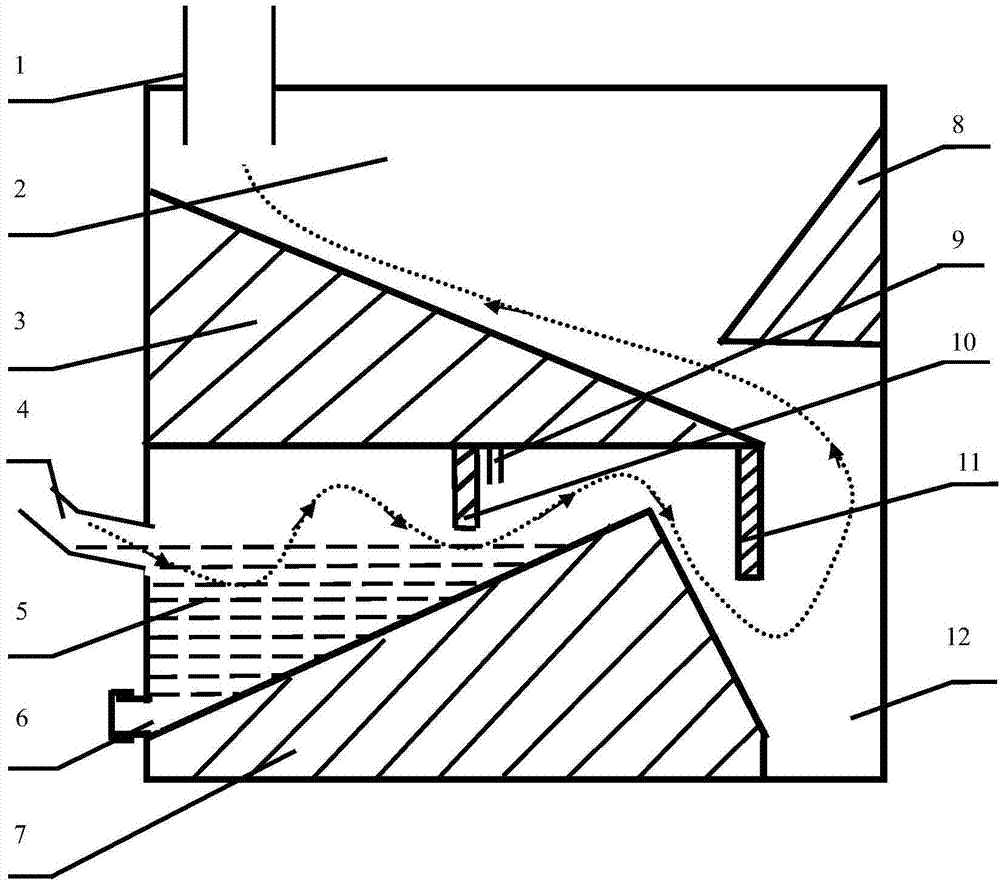

[0009] A structure and method of use of the present invention applied to a small coal-fired boiler dedusting device are described in detail below:

[0010] The device is built at the dust outlet of the boiler. The material is brick and reinforced concrete, and the length, width and height are 3 meters, 2 meters and 2 meters respectively. It is divided into two parts, one is the upper room, including the dust collection room in the upper room, the upper room Italic 1, the upper room Italic 2, and the chimney; the second is the lower room, including the smoke and dust inlet, the sink, the dust outlet 1, and the dust outlet 2 , Italics in the lower chamber, inclined plate one in the lower chamber, inclined plate two in the lower chamber, automatic water replenishment port.

[0011] The specific operation is as follows: start the fan, and under the action of the fan, the smoke and dust are blown from the smoke and dust inlet into the sink in the lower room, arousing a large amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com