Automatic liquid adding device of underground coal mine emulsified liquid

A liquid adding device and emulsification technology, applied in chemical instruments and methods, dissolving, mixers, etc., can solve the problems of corrosion, inoperability, slow running of the bracket, etc., and achieve the effects of convenient use, simple design and production, and simple replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

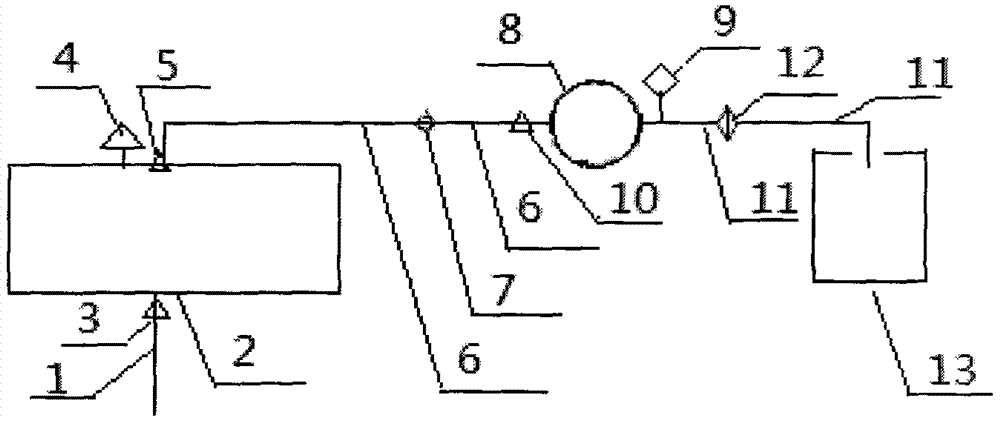

[0008] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0009] Such as figure 1 Shown, a kind of coal mine underground emulsion liquid adding device of the present invention, by liquid device by emulsion tank 2, liquid inlet pipe 6, liquid outlet pipe 1, filter 12, check valve 7, liquid level switch 4 and liquid adding The two ends of the emulsion tank 2 are connected with two flanges 3 and 5, and the liquid inlet pipe 6 and the liquid outlet pipe 1 are connected, and the liquid inlet pipe 6 and the liquid outlet pipe 1 are respectively connected to the On the emulsion tank 2 and the filling pump 8, the catheter 11 on the other side of the filling pump 8 is connected to the emulsion tank 13, the liquid level switch 4 is installed on the top of the emulsion tank 2, the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com