Method for making wine by applying multi-microorganism bacterial solution

A multi-microorganism and bacterial liquid technology, which is applied in the field of winemaking, can solve the problems of insufficiency of microbial screening and enrichment, and achieve the effects of saving labor input, fragrant aroma, and increasing the content of characteristic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Production of multi-microbial bacteria liquid according to the following steps

[0019] (1) The multi-microbe liquid is obtained by mixing the mixed bacterial liquid and the mixed yeast liquid at a mass ratio of 3:1;

[0020] (2) The concentration of bacteria in the bacterial mixture is 1×10 9 / ml, containing Bacillus subtilis (Bacillus subtilis) CCTCC AB 130007, Bacillus subtilis (Bacillus subtilis) CCTCC AB 130018, Bacillus licheniformis (Bacillus licheniformis) CCTCC AB 91060, Bacillus circulans (Bacillus circulans) CCTCC AB207850 The mass ratio between the bacterial liquid is 3:2:1:1. The mixed bacteria liquid is obtained by inoculating each pure species of bacteria into the beef extract peptone liquid medium with a pH value of 7.2, culturing at 37°C for 24 hours in a digitally controlled fermentation tank, and stepwisely expanding the culture at an inoculum amount of 10% and mixing;

[0021] (3) The concentration of yeast in the yeast mixture is 1×10 8 / ml, con...

Embodiment 2

[0023] Example 2 Brewing liquor using multi-microbe liquid

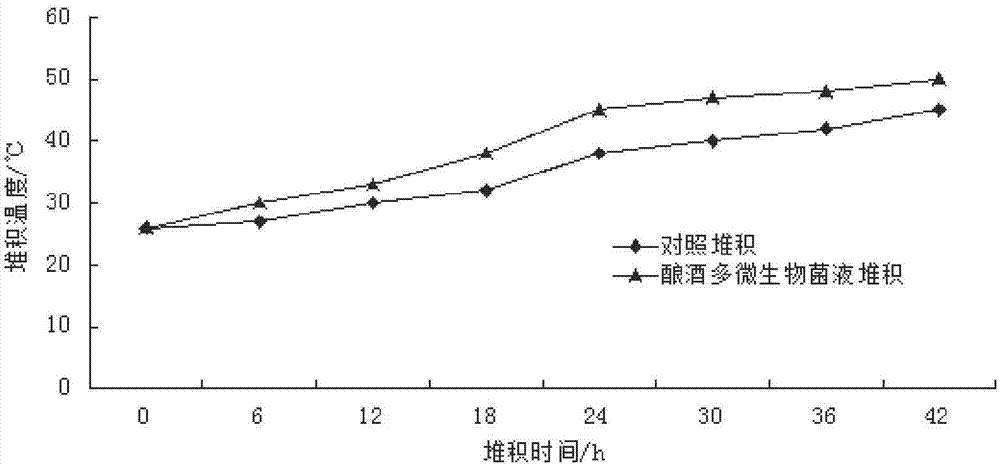

[0024] (1) When the amount of grain is 1000kg, mix 50L of the multi-microbial bacteria liquid with the grains evenly, control the moisture of the grains to 50%, the temperature is 30℃, and pile the grains into a trapezoidal long pile;

[0025] (2) The stacking temperature will gradually increase. When stacking for 40-45 hours and the temperature reaches 45°C or higher, ventilate the stack to lower the temperature and reduce the temperature to 30°C;

[0026] (3) Mix 20L of multi-microbial bacteria liquid with 30℃ grain mash, and ferment in the tank;

[0027] (4) Other processes not involved are the same as the original wine-making production process.

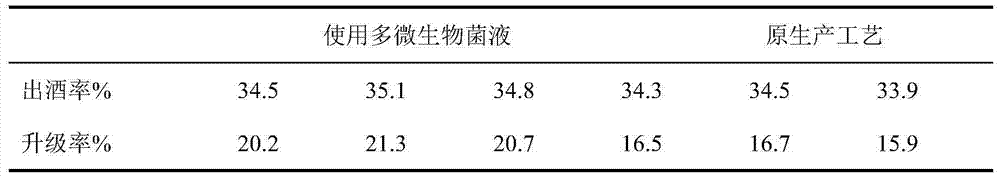

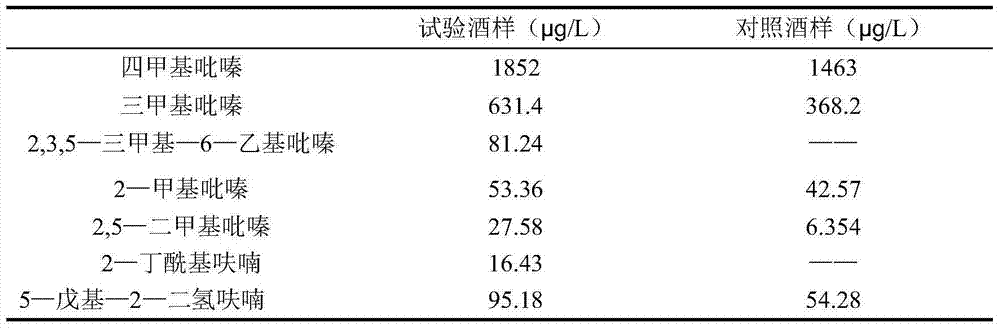

[0028] From figure 1 , The data in Tables 1 and 2 can be seen: the use of multi-microbial bacteria liquid technology can significantly increase the upgrade rate of wine, and the rate of wine production is basically stable; it can effectively increase the temperature of grain acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com