A device and method for separating antimony-containing alloys

An antimony alloy and molten pool technology is applied in the field of devices for separating antimony-containing alloys, and can solve the problems of difficult operation, no use value, and large loss of molten salt volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

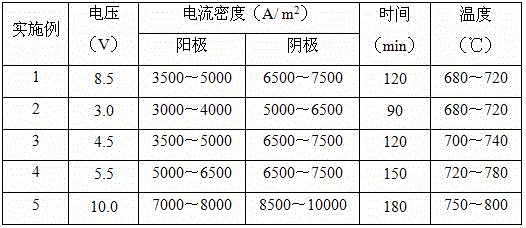

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0046] At first introduce the structure of the device embodiment of separating high lead-antimony alloy or noble antimony of the present invention:

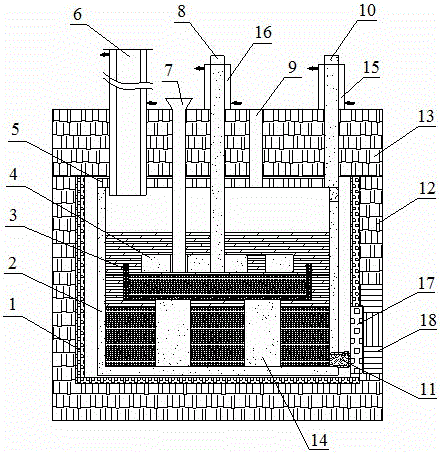

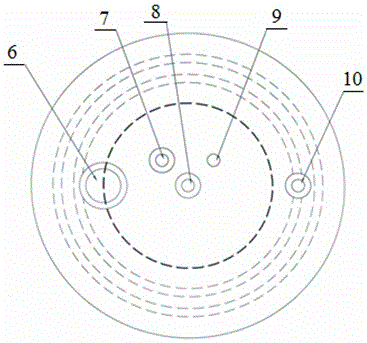

[0047] Such as figure 1 As shown, it includes heating furnace 1, cathode molten pool 2, anode molten pool 3, anode plate 4 with openings, return pipe 6, hopper 7, anode graphite rod 8, cathode graphite rod 10 and cathode slag discharge valve 11. Both the cathode molten pool 2 and the anode plate 4 are made of graphite, and the cathode slag discharge valve 11 is a graphite sealing plug with interference fit; the cathode molten pool 2 is located in the heating furnace 1 and covered with the cathode molten pool Cover plate 5, the cathode molten pool cover plate 5 is connected to the cathode graphite rod 10; the anode molten pool 3 is suspended in the cathode molten pool 2, the anode graphite rod 8 passes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com