Glass curtain wall with vacuum thermal baffle

A technology of vacuum insulation panel and glass curtain wall, which is applied in the direction of wall, climate change adaptation, insulation improvement, etc. The effect of long service life, improved integrity and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

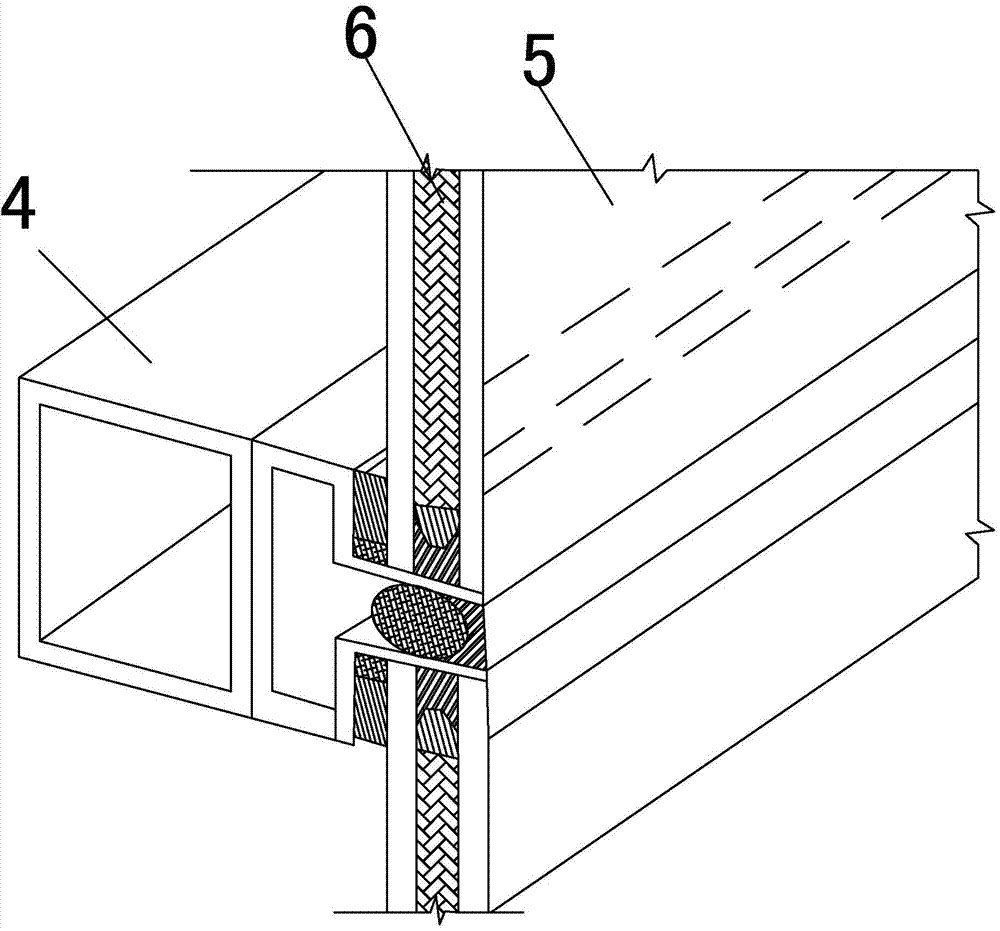

[0030] See figure 1 , the glass curtain wall of this embodiment includes: a supporting structure 4 of metal material suspended on the main structure of the building, and a plurality of hollow glass 5 arranged on the supporting structure 4, wherein only the said A vacuum insulation panel 6 is provided in the interlayer space of the insulating glass 5 .

[0031] The insulating glass 5 is a two-layer insulating glass, and the vacuum insulation panel 6 is pasted on the inner wall of the outer glass of the insulating glass to prevent glass fragments from falling when the outer glass self-explodes and ensure safe use.

[0032] As another embodiment, the insulating glass is triple-layer insulating glass, and the triple-layer insulating glass includes inner and outer interlayer spaces, and the vacuum insulation board is arranged in the inner interlayer space and / or the outer interlayer space to Prevent glass fragments from falling when the glass self-explodes, ensuring safe use. Whe...

Embodiment 2

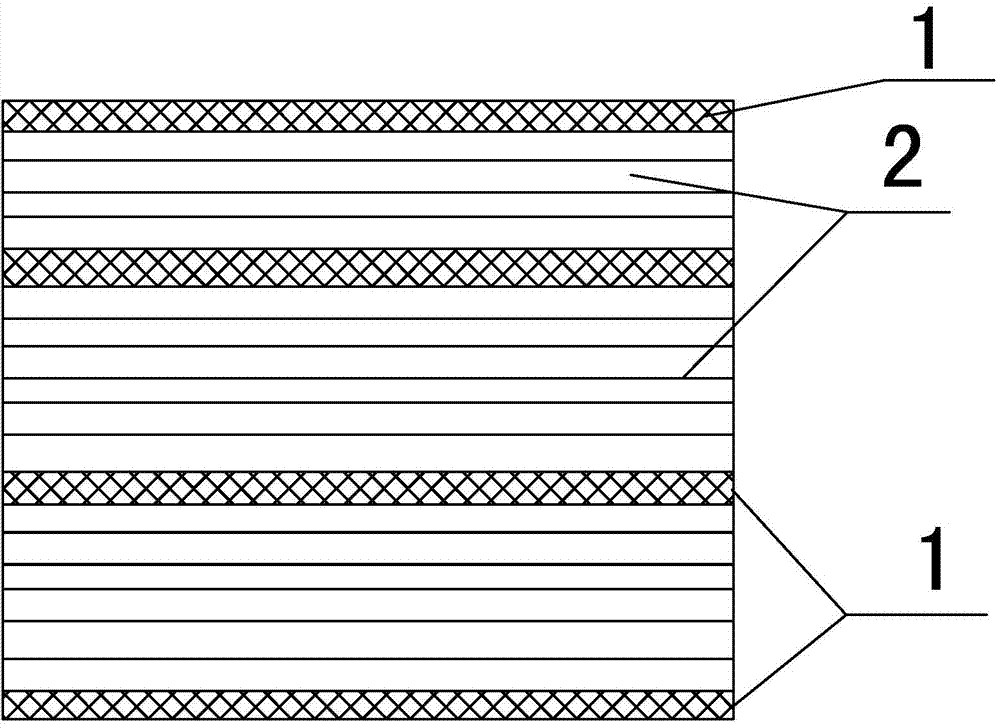

[0042] Such as image 3 , the core material of the vacuum insulation panel in this example includes a multi-layer glass fiber sheet 2 formed by a wet papermaking method (that is, a chopped strand core material) and 2-5 layers of gas-phase SiO 2 An intermediate core material composed of powder layers or plates 1 alternately stacked; the entire intermediate core material is wrapped by an ultra-fine glass fiber cotton sheet 3, and the fibers in the ultra-fine glass fiber cotton sheet 3 have a diameter of 1-4um and a length of 1 -5mm, the thermal conductivity of the VIP made of this core material is 3.0-4.0mW / m.k, and the service life is not less than 30 years.

[0043] As a variable implementation manner, the intermediate core material is arranged in a bag body composed of the above-mentioned ultra-fine glass fiber cotton sheet, or the above-mentioned ultra-fine glass fiber cotton sheet wraps the surrounding edges of the intermediate core material.

Embodiment 3

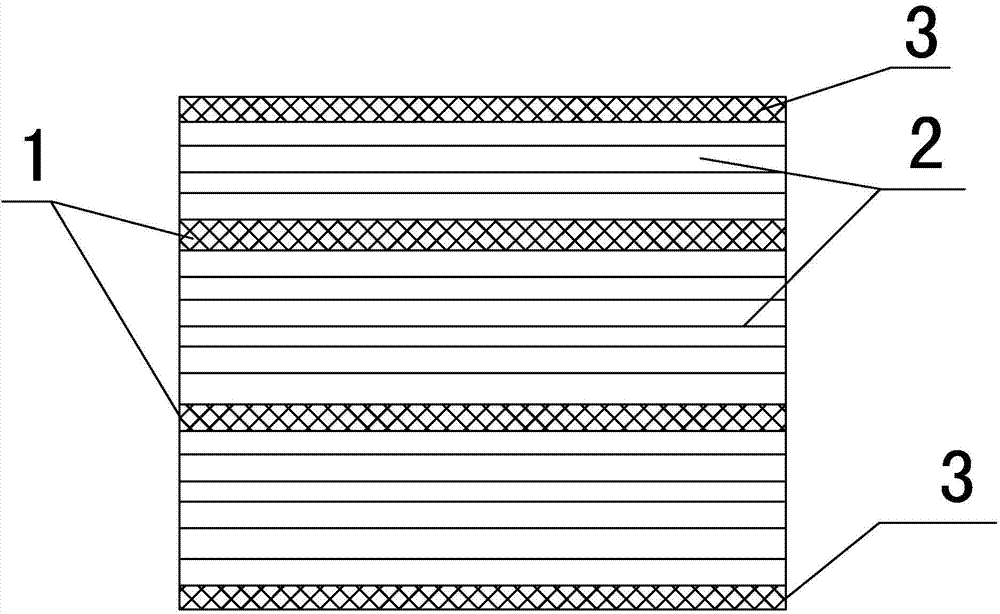

[0045] Such as Figure 4 , the vacuum insulation panel core material in this example includes 10-30 layers of glass fiber sheet 2 formed by wet papermaking method (ie chopped strand core material) and 2-10 layers of gas phase SiO 2 An intermediate core material composed of powder layers or plates 1 alternately laminated; the upper and lower sides of the intermediate core material are covered with SiO 2 Board 1 and ultra-fine glass fiber cotton sheet 3, the ultra-fine glass fiber cotton sheet 3 covers the four sides of the middle core material at the same time; the fiber diameter in the ultra-fine glass fiber cotton sheet 3 is 1-4um , The length is 1-5mm, the thermal conductivity of the vacuum insulation panel made of this core material is 3.0-4.0mW / m.k, and the service life is not less than 30 years.

[0046] The glass fiber sheet is formed by a wet papermaking method from glass fiber chopped strands produced by a drawing method with a diameter of 6-13um and a length of 4-20m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com