Three-dimensional wave velocity imaging measurement-while-drilling method and device for rock in front of tunnel face

A measurement-while-drilling, face-to-face technology, used in measurement devices, earthwork drilling, geophysical measurement, etc., can solve the problems of large observation space, accurate detection of bad geological bodies, false positives and missed reports of geological bodies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

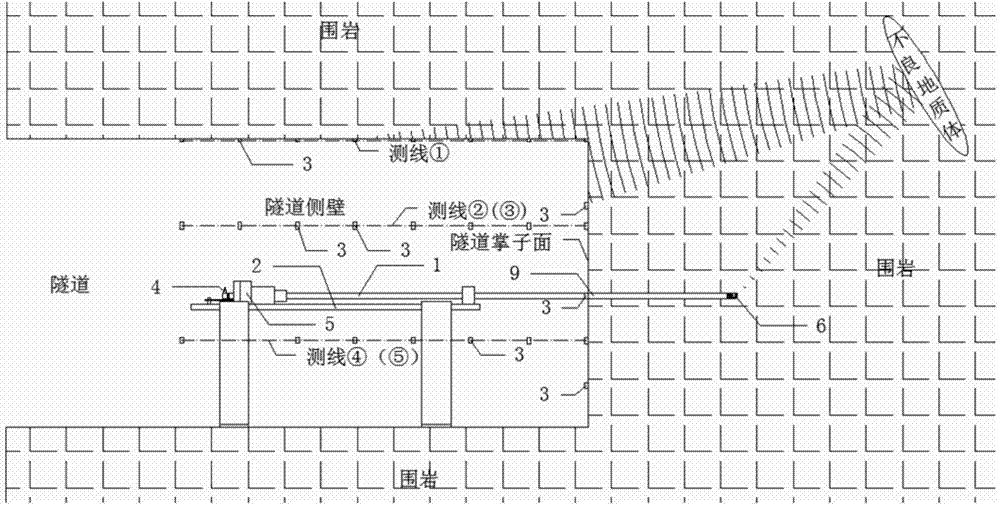

[0093] Such as figure 1 Shown is the overall schematic diagram of the tunnel seismic three-dimensional advanced geological detection method and device.

[0094] First of all, according to the quality grade of the rock mass where the face is located, the risk is eliminated on the face of the face. If the strength of the rock mass is grade 4 or 5, the flatness of the face of the face needs to be processed to ensure that the face of the face is The surface is relatively flat, so that the geophones can be arranged on a plane. If the grade of rock mass on the face of the face is of other strengths, the face of the face needs to be sprayed and anchored with concrete to ensure that the rock mass on the face of the face will not fall off during the drilling process of the advanced drilling rig, so as to ensure that the earthquake prediction while drilling proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com